- – Robot offline programming software with independent intellectual property rights

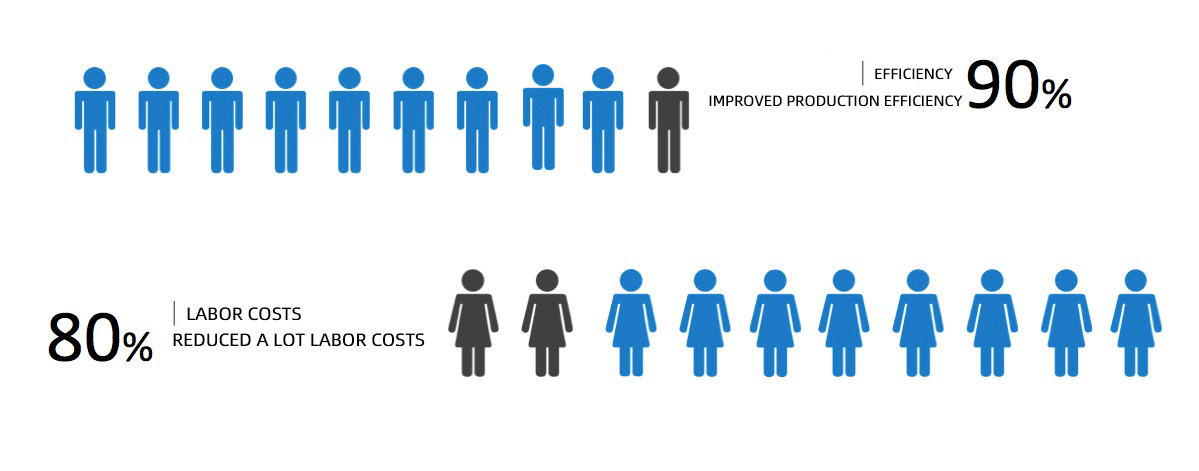

- – Specially designed for practical industrial application requirements

- – InteRobot supports HuazhongCNC, ABB, KUKA, Yaskawa, Kawasaki and etc. industrial robots

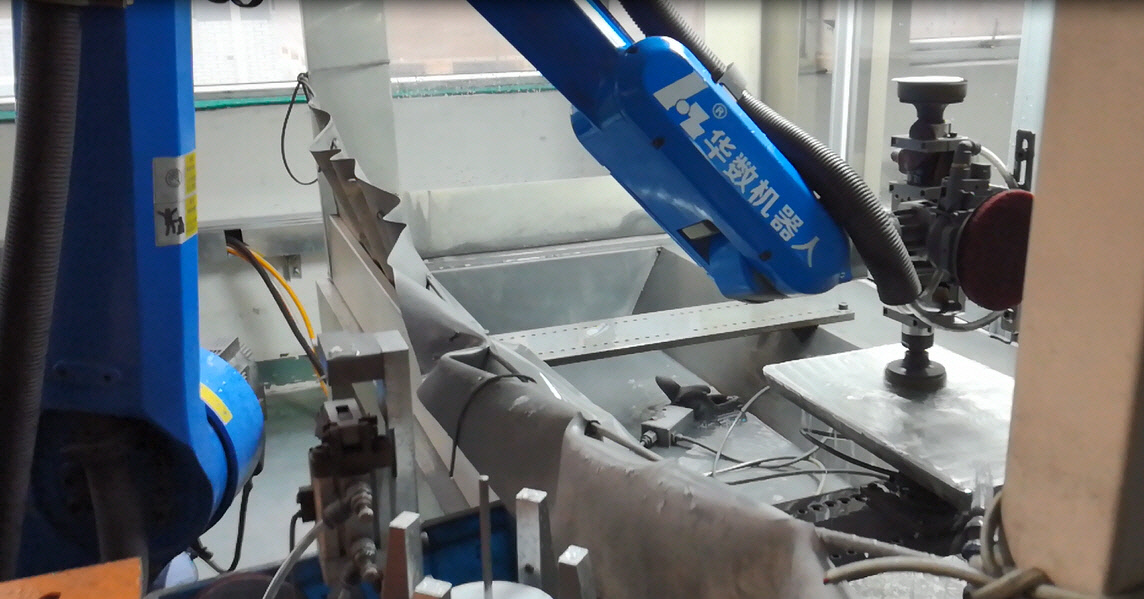

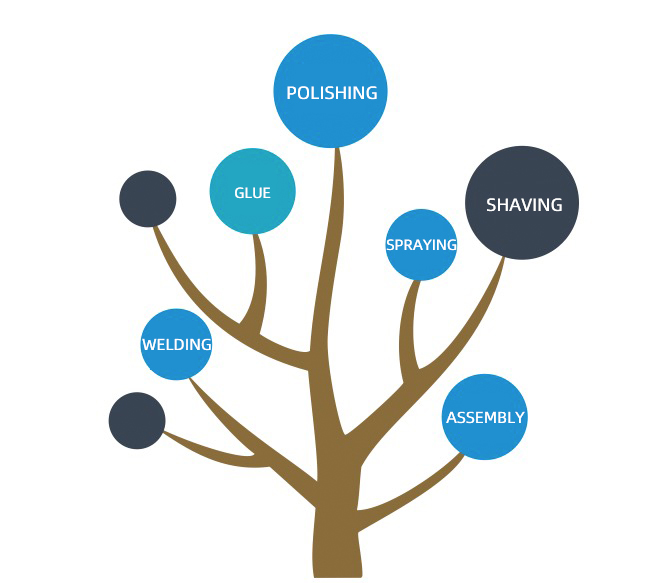

- – Widely used in various areas such as metal parts, molding making, spraying, multi-axis machining and more.

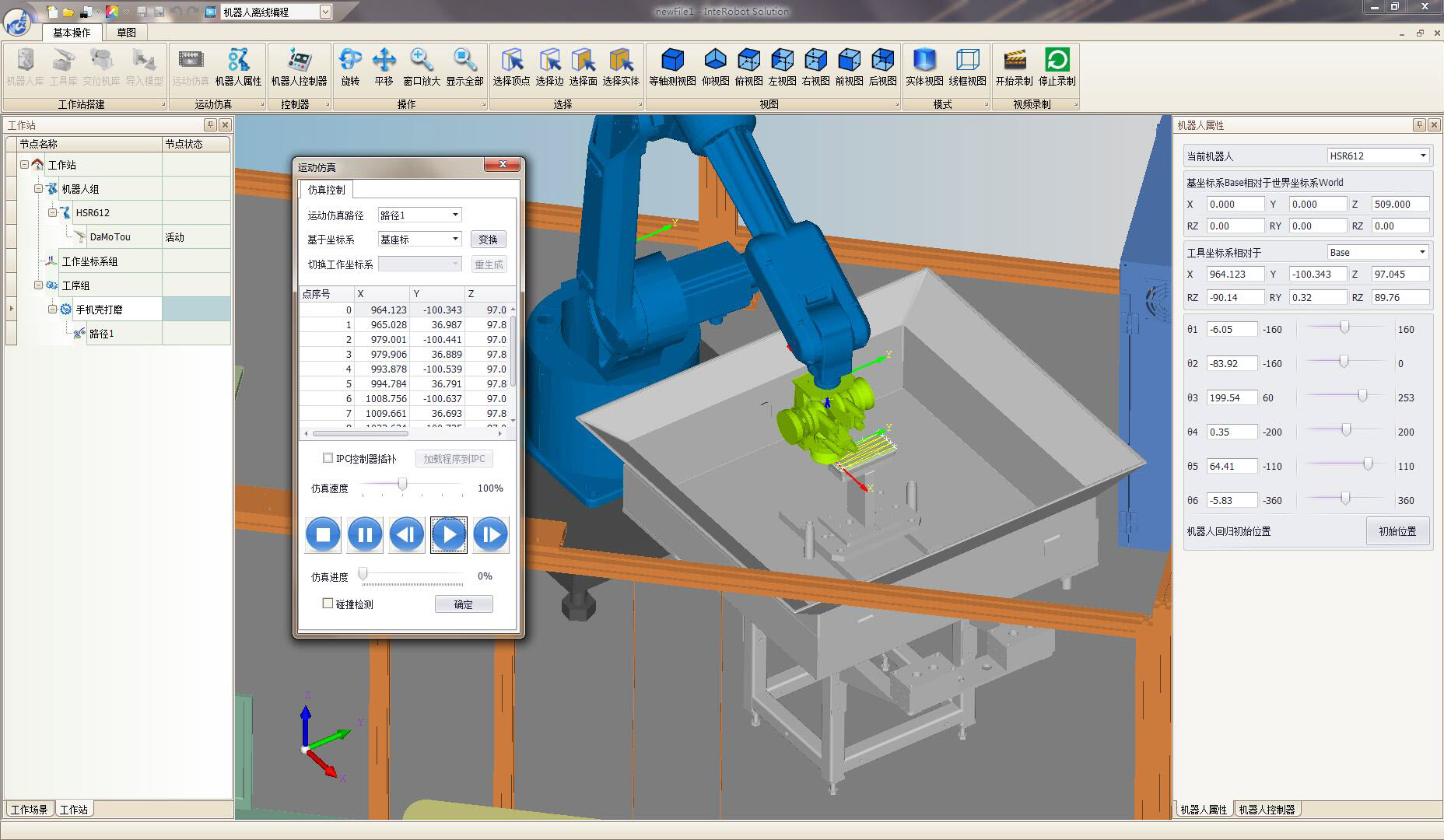

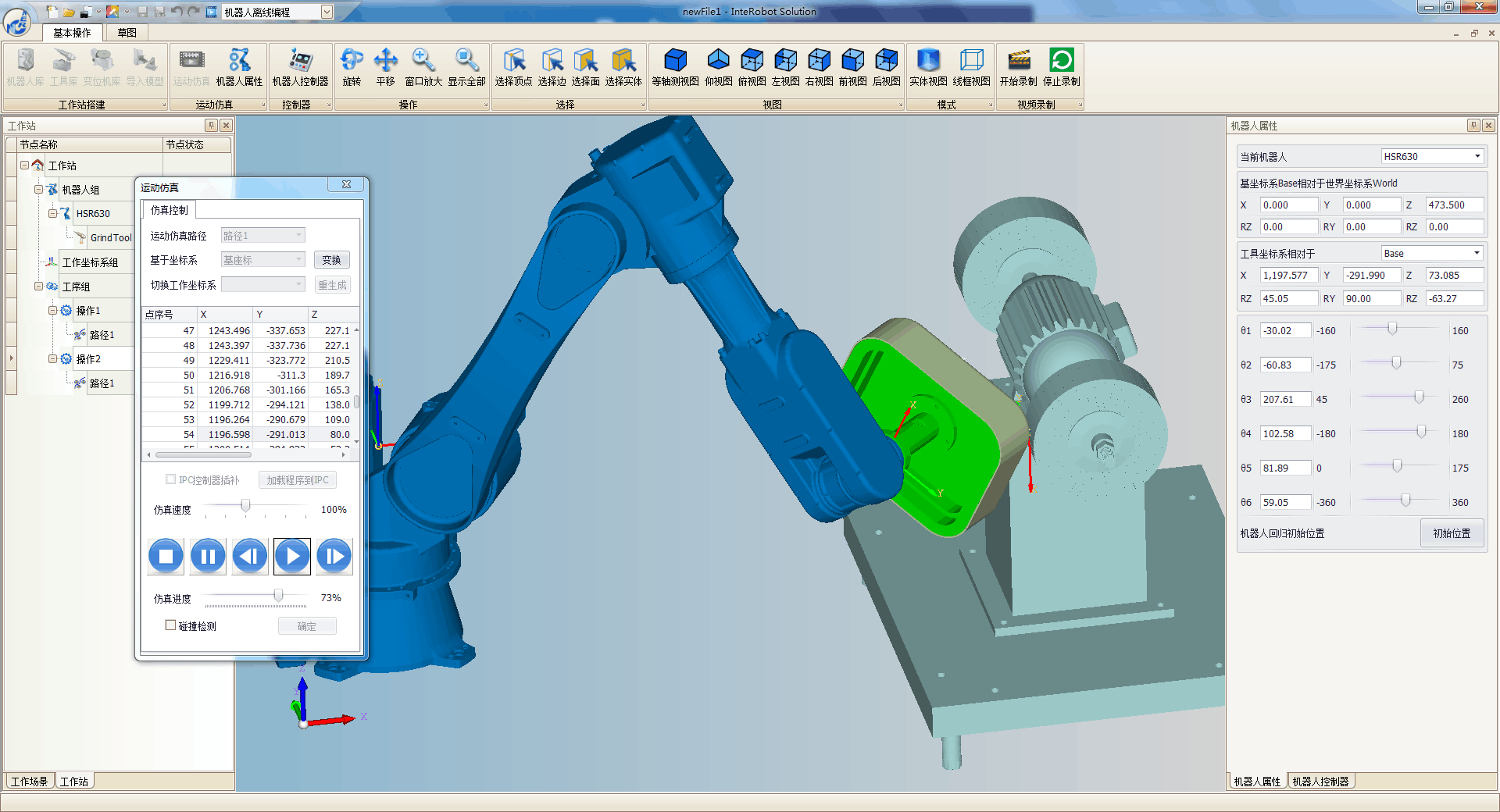

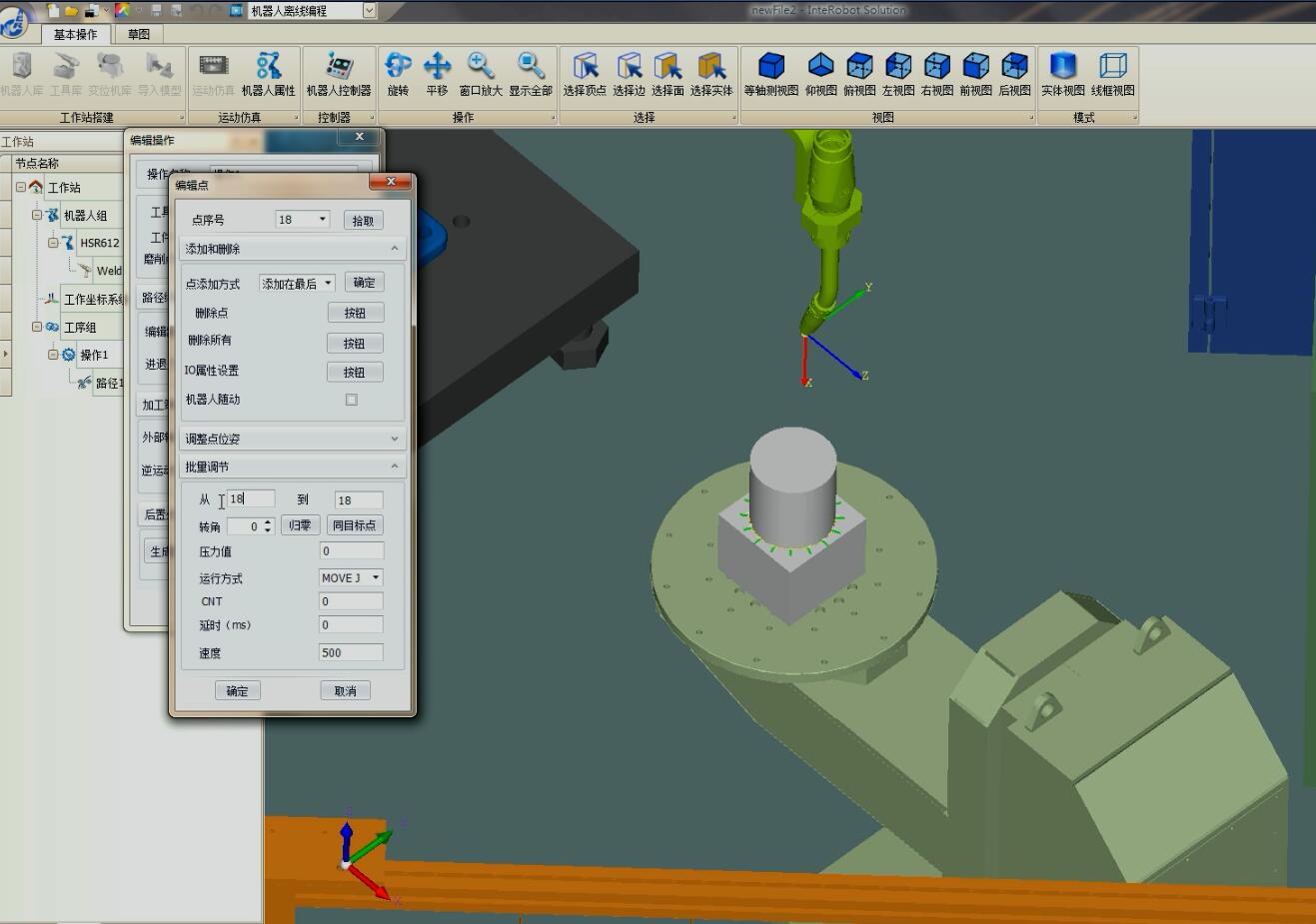

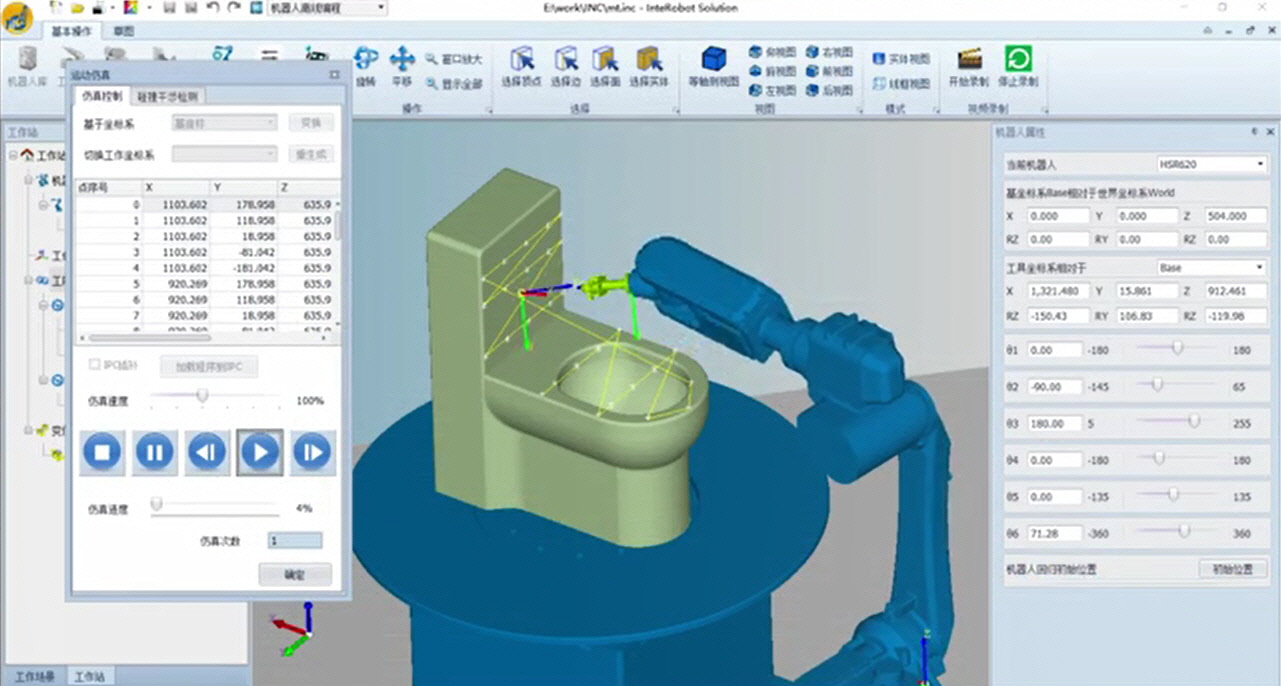

- – Rich offline programming features such as robot library management, tool library management, processing method selection, processing path planning, kinematics solution, robot selection, control parameter setting, anti-collision and interference checking, kinematics simulation and etc.

InteRobot is a professional industrial robot offline programming and simulation software which has been deeply integrated with the process requirements of the application field. The software is easy to use as it is designed with intuitive user interface and clear functional planning.