- Fast movement: the working cycle can be as high as 16 times/min, effectively improving production efficiency.

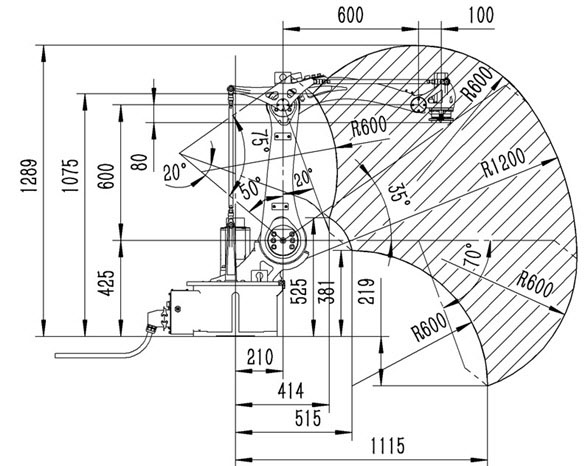

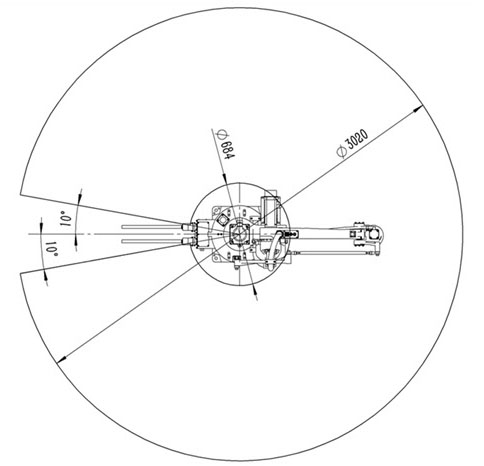

- Large range of motion: the maximum working radius can reach 1510mm, which can be easily applied to punching occasions where the center distance of the punch is 3m.

- Cost-effective: compared with the 6-joint robot, this automated case palletizer robot adopts a 4-joint design, which effectively reduces the input cost and can meet various handling and palletizing applications.

- Easy maintenance: the robotic bag palletizer has a simple structure, adopting a modular component structure and a combined deceleration mechanism, with low difficulty in fault maintenance, and can quickly restore production after troubleshooting.

- High reliability: the whole machine adopts high-performance core components, with low stability and low failure rate, which provides high-reliability performance guarantee for the whole machine, and can continuously perform production tasks for a long time.

- Multiple uses: it is widely used for handling in hot forging, stamping, machine loading and unloading industries, and for palletizing egg, case and bag and etc.

- Strong scalability: it can flexibly arrange and adjust the production connection method according to the actual production needs, and can quickly realize flexible production and follow-up plans to change the design and expand the application.