Model

Axis

Working radius

Payload

RJR680 is the latest launch of a general type medium-large load six-axis robot. At the beginning of R&D design, a variety of operating conditions are considered such as load and upload, handling, welding, polishing, and so on. Its performance has reached the advanced level of similar products.

1, High rigidity and high speed: the whole machine design uses finite element analysis to analyze the core mechanics, combining with the rich robot design experience of HCNC ROBOT, casting the excellent structural rigidity of the HSR-JR680; at the same time, through optimizing the motor selection and reduction ratio configuration, the end synthesis speed of the whole machine can be up to 4 m/s.

2, High-precision: in order to meet the works with strict requirements on the precision of the trajectory such as welding, polishing, and deburring, the RJR680 transmission system has been carefully designed and rigorously assembled to eliminate the drive line transmission errors as much as possible so that the re-positioning accuracy can reach ±0.07 mm. RJR680 is at an advanced level compared to similar products in the mainland.

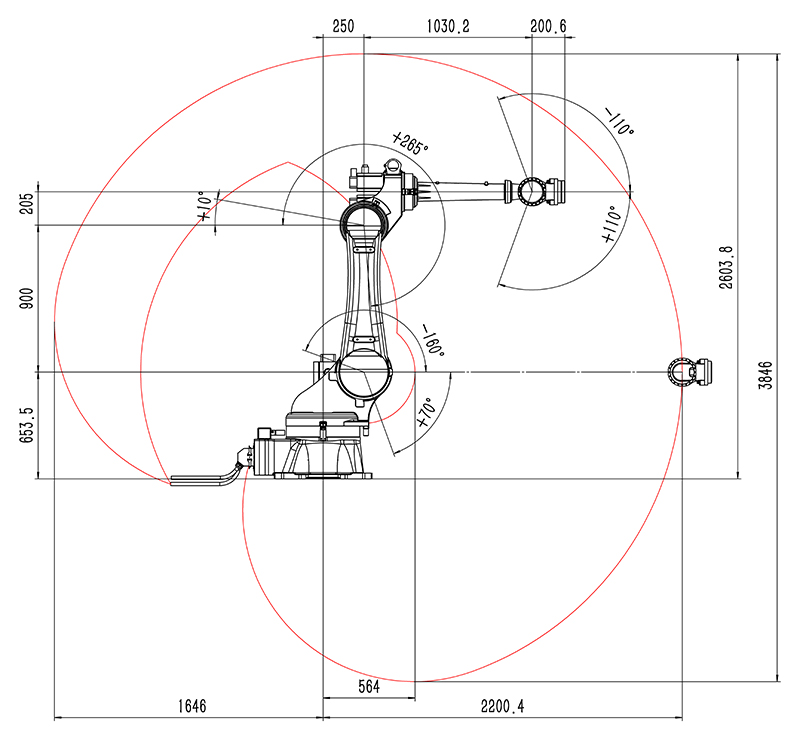

3, Wide working range: The arm span is 2200 mm, which can cover many working scenes. The wrist structure is compact and can be flexibly rotated in a narrow space.

4, High loading: the load allowance of the fourth, fifth, and sixth joints reaches 25% can eliminate the tight weight control during the fixture design so that it can leave more room for design. In some cases, it can be used as a 100 kg load robot. Besides, the extra safety margin means a higher safety factor and longer service life.

5, High protection: arm protection level up to IP65 which can prevent dust, waste, and liquid pollution, and it is suitable to use in harsh conditions such as polishing and deburring. It can also provide continuous and stable products as well as reduce maintenance costs to create more value for you.

| Material handling robot | RJR680 | |

| Degree of freedom | 6 | |

| Payload | 80Kg | |

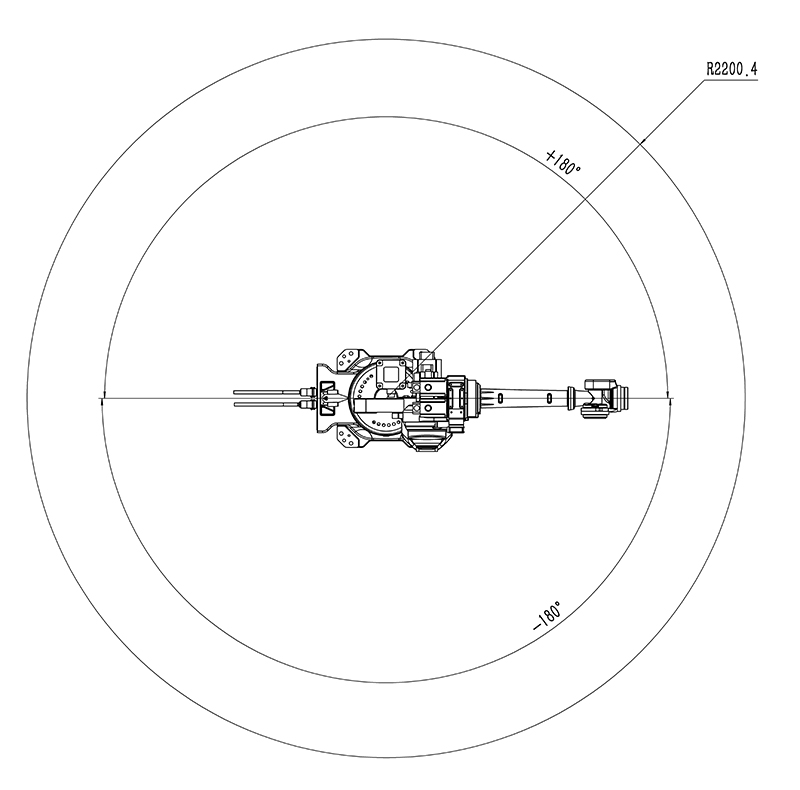

| Maximum working radius | 2200.4mm | |

| Repeated precision | ±0.07mm | |

| Range of motion |

J1 |

±180° |

| J2 | -160°/70° | |

| J3 | +10°/265° | |

| J4 | ±360° | |

| J5 | ±110° | |

| J6 | ±360° | |

| Rated speed |

J1 |

85°/s, 1.48rad/s |

| J2 | 85°/s, 1.48rad/s | |

| J3 | 104°/s, 1.81rad/s | |

| J4 | 177°/s, 3.08rad/s | |

| J5 | 155°/s, 2.7rad/s | |

| J6 | 187°/s, 3.26rad/s | |

| Maximum speed |

J1 |

127.5°/s, 2.22rad/s |

| J2 | 127.5°/s, 2.22rad/s | |

| J3 | 104°/s, 1.81rad/s | |

| J4 | 177°/s, 3.08rad/s | |

| J5 | 155°/s, 2.7rad/s | |

| J6 | 187°/s, 3.26rad/s | |

|

Allowable moment of inertia |

J6 |

25kg㎡ |

| J5 | 32.7kg㎡ | |

| J4 | 32.7kg㎡ | |

| Allowable torque |

J6 |

330Nm |

| J5 | 340Nm | |

| J4 | 400Nm | |

| Applicable environment |

Temperature |

0~45° |

| Humidity | 20%~80% | |

| Others | Avoid contact with flammable, explosive or corrosive gases and liquids. Keep away from electronic noise sources (plasma). | |

| Cable Length of Instructor | 8metre | |

| Body-cabinet connection length | 8metre | |

| I/O parameters | Digital: 32 inputs, 31 outputs (one for control cabinet fault indicator output) | |

| Battery capacity | 7.5kVA | |

| Rated power | 6kW | |

| Rated voltage | 3-phase AC380V | |

| Rated current | 10.8A | |

| Body protection grade | IP53 | |

| Installation method | On the ground | |

| Body weight | 722kg | |

| Control cabinet protection grade | IP53 | |

| Control cabinet size | 700mm(wide)×500mm(thick)×1300mm(high)-vertical | |

| Control cabinet weight | 180KG | |

In the history of more than 30 years of development, it has won many awards and more than 1,000 patent certifications.