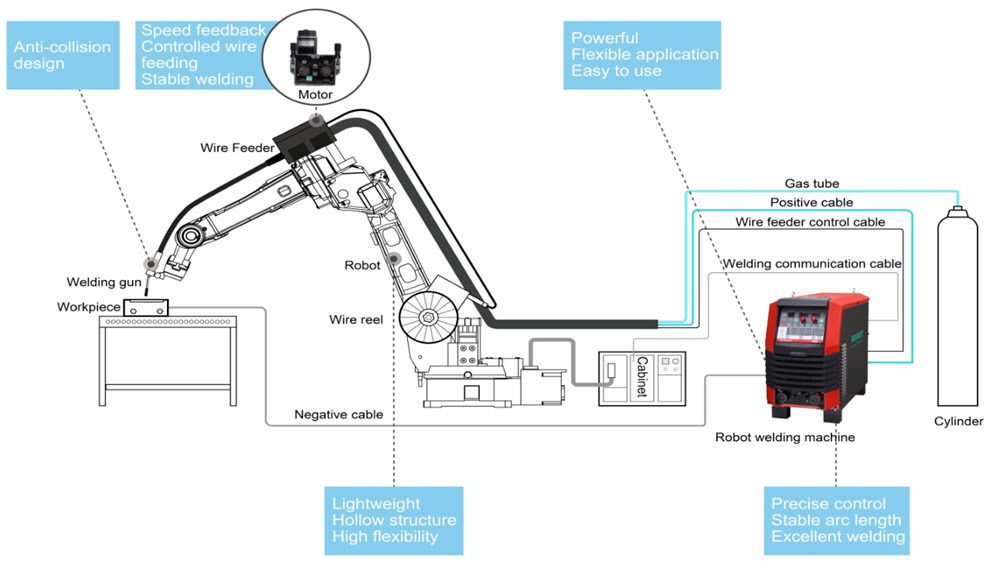

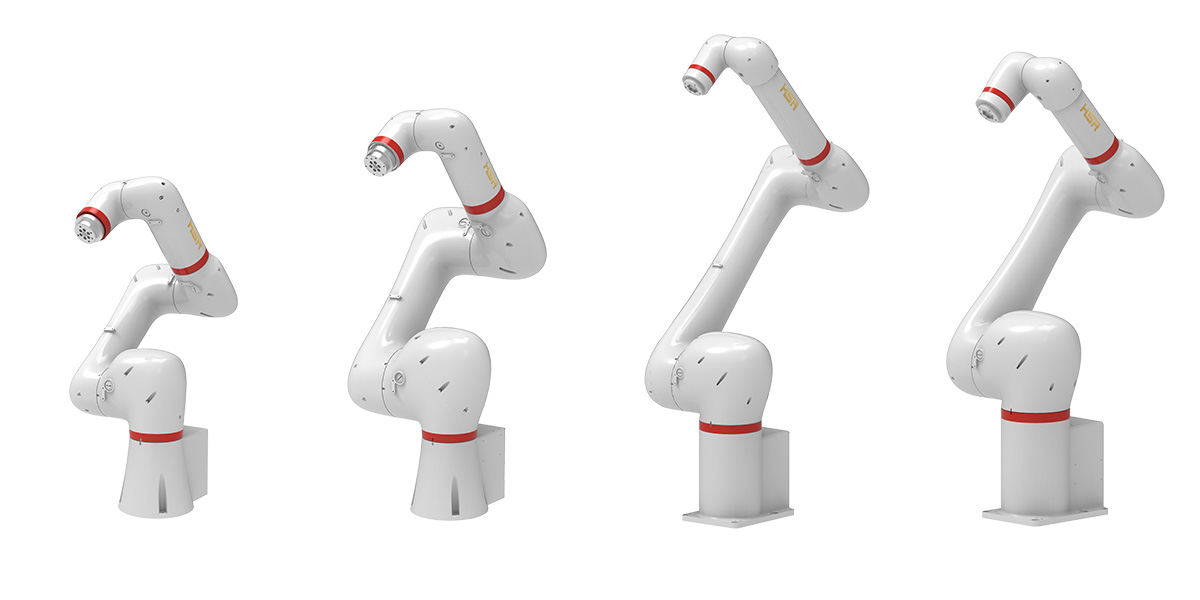

Welding Robotic Arm

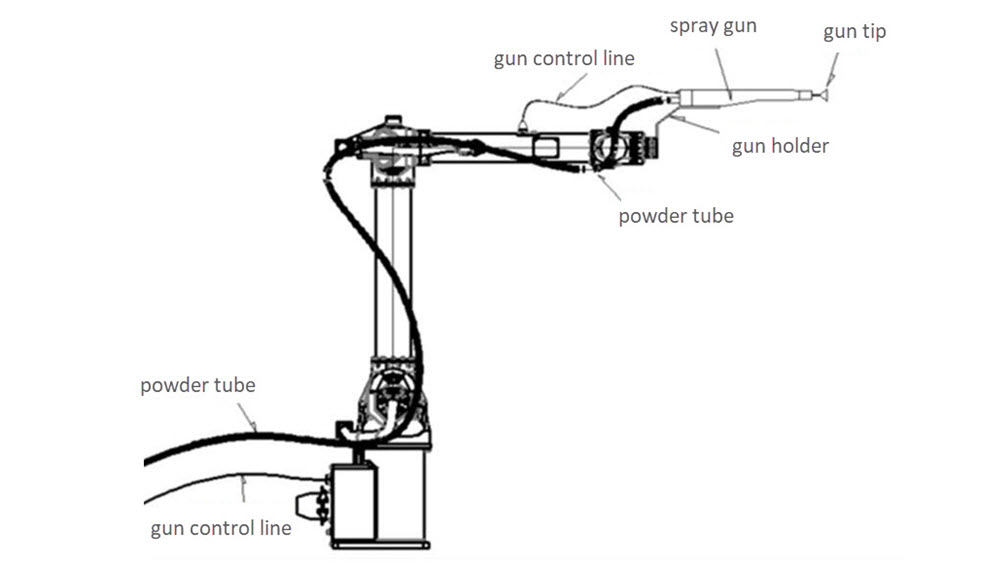

HNC-RJH series welding robots are specially designed and developed for automatic welding. At present, Welding robot arms including HNC-RJH605 and HNC-RJH615.

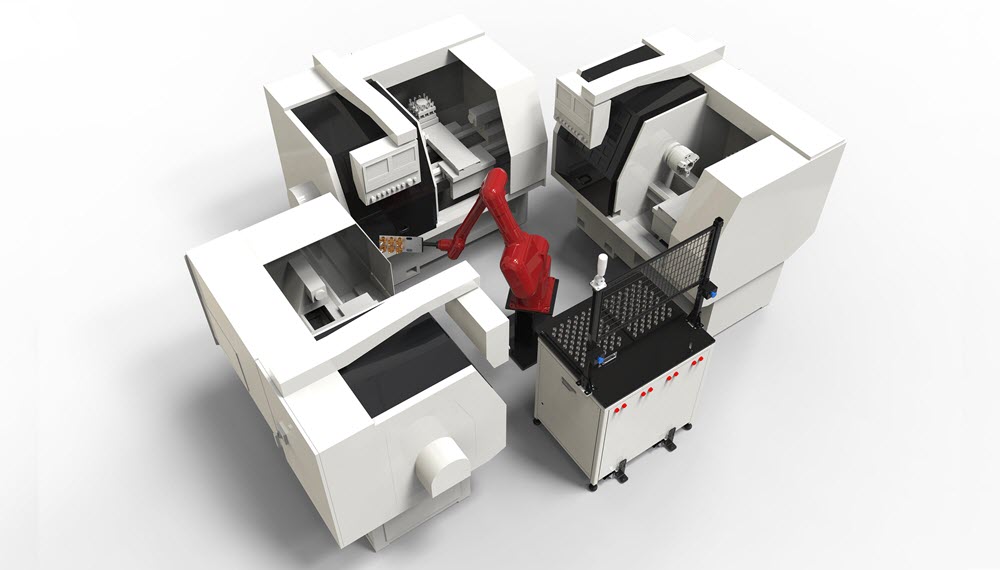

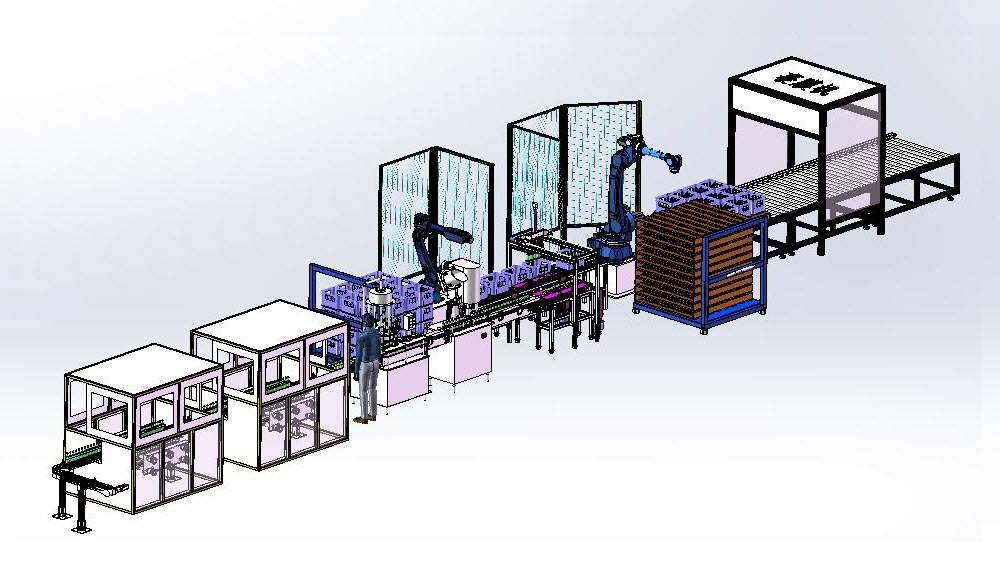

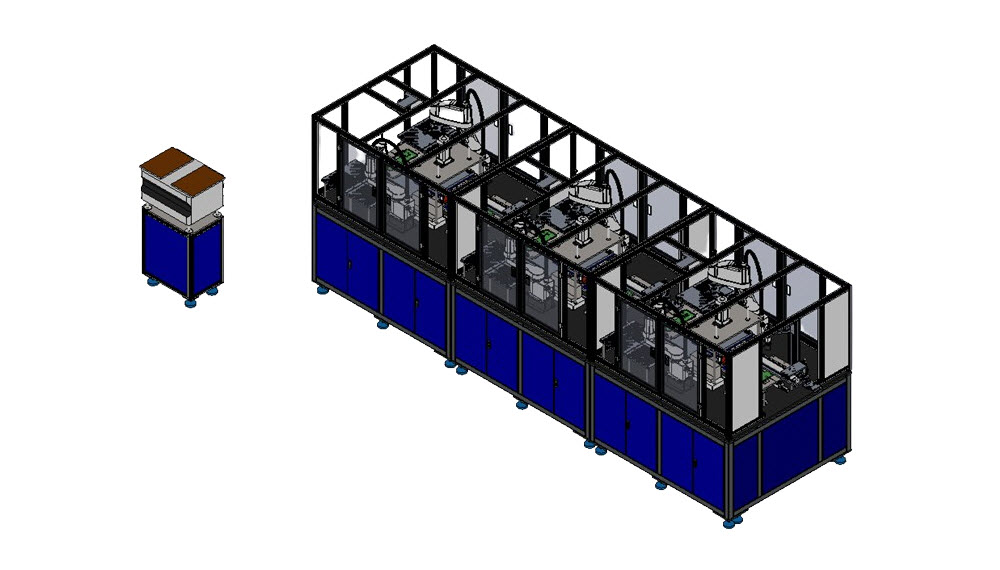

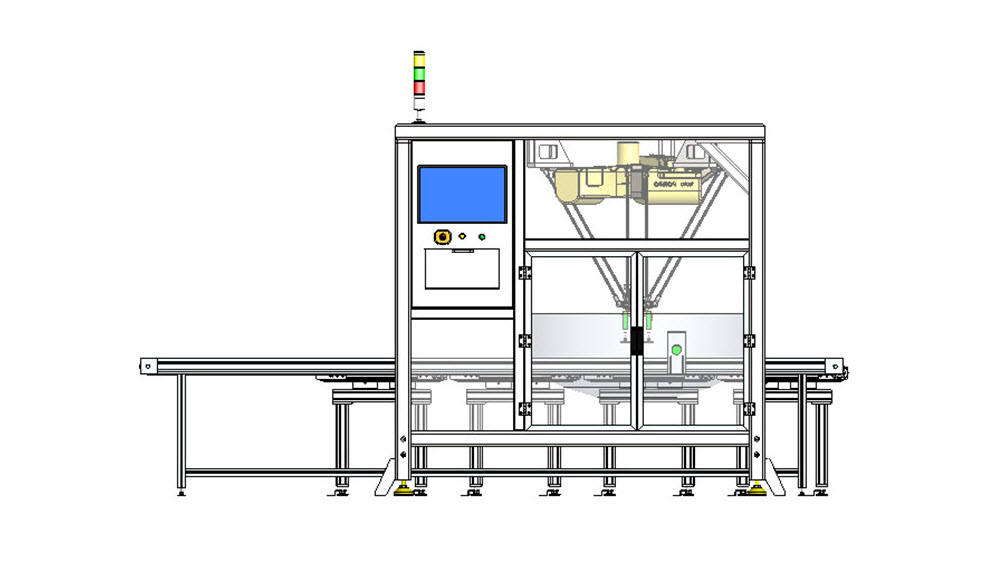

The robotic welding cell integrates a welding machine, welding gun and wire feeder, and has a built-in professional welding process. It can carry out arc welding (MAG welding / MIG welding / CO2 welding) and laser welding.

It is widely used in automobiles, motorcycles, hardware, steel structure, plate, sheet metal, and other industries.