In the preliminary scheme design and subsequent scheme implementation process, HNC-RJR series machine loading and unloading robots are equipped with offline programming simulation software for customers to use, which can predict potential problems and program complex tasks, thereby increasing the reliability of the robotic loading scheme and enhancing the stability of the scheme implementation.

Machine Loading & Unloading Robot

Get A Free Quote

Products List

Application & Configuration

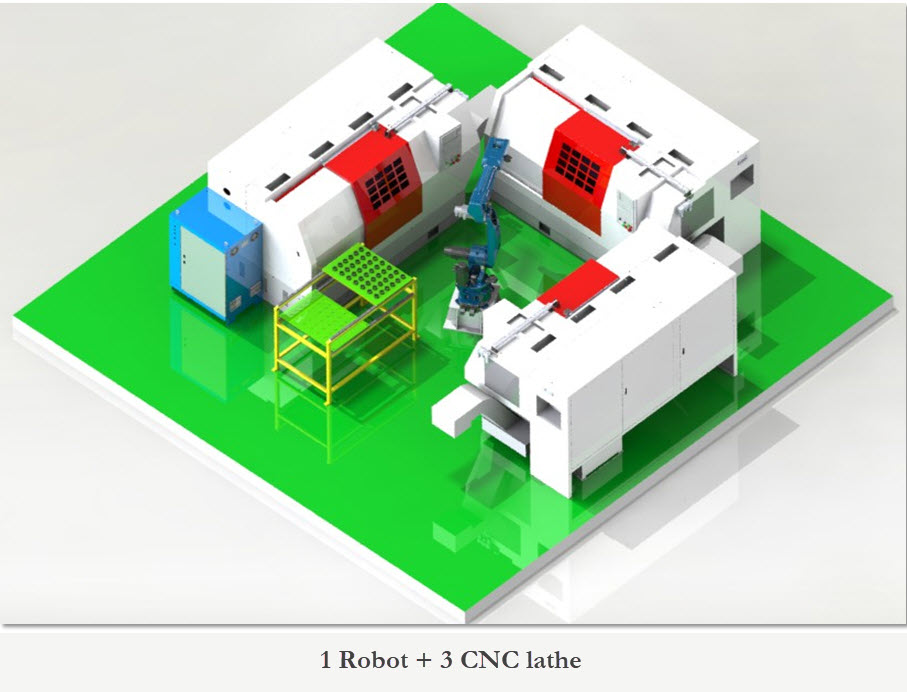

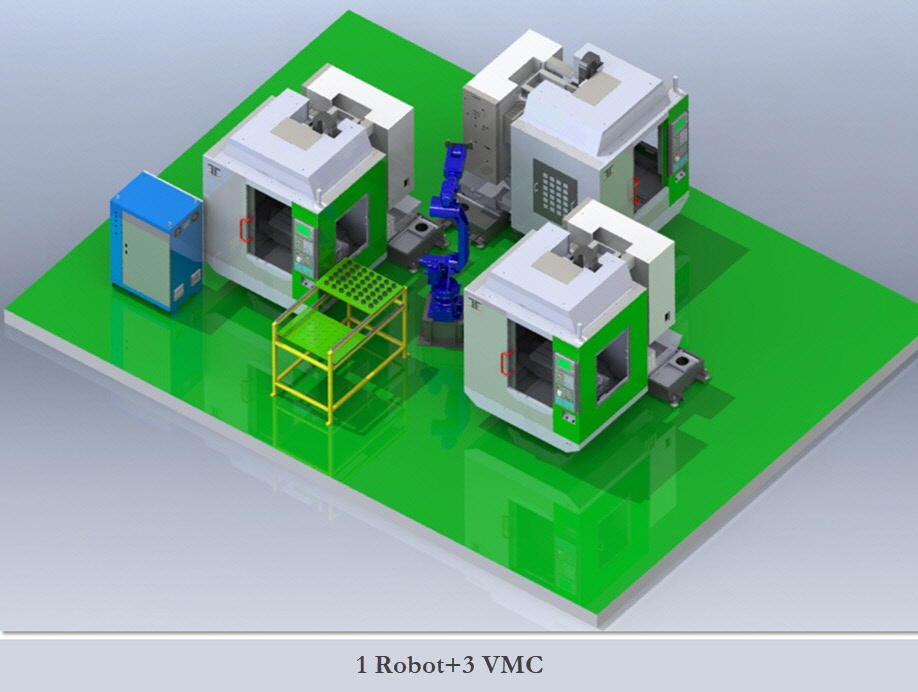

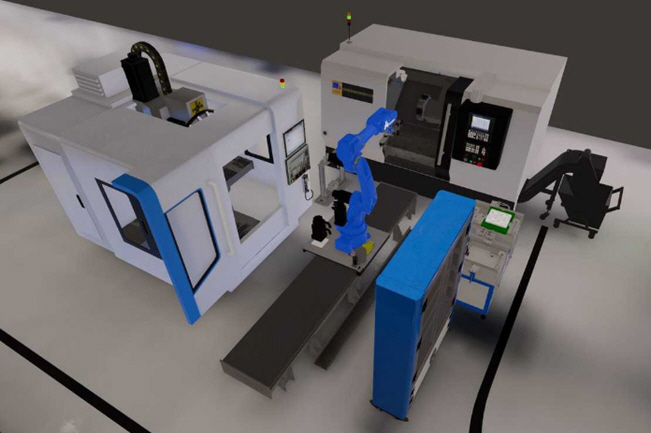

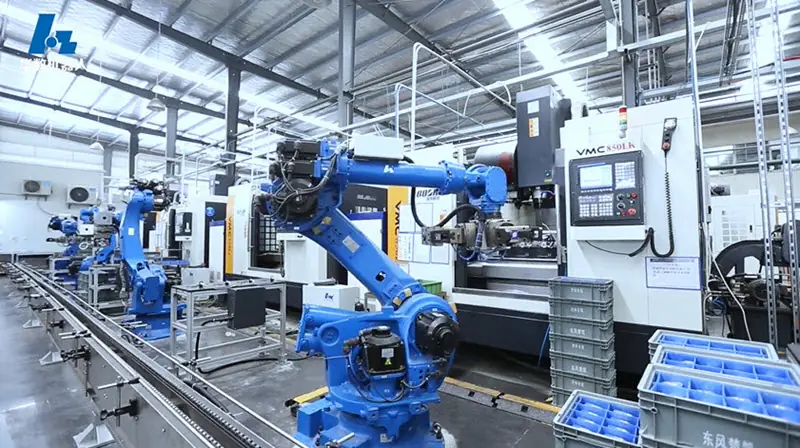

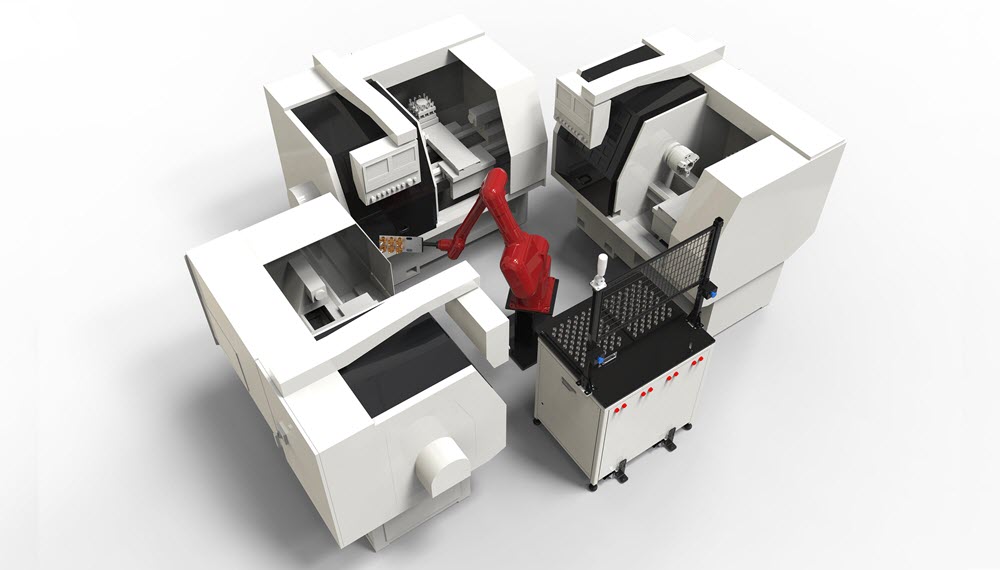

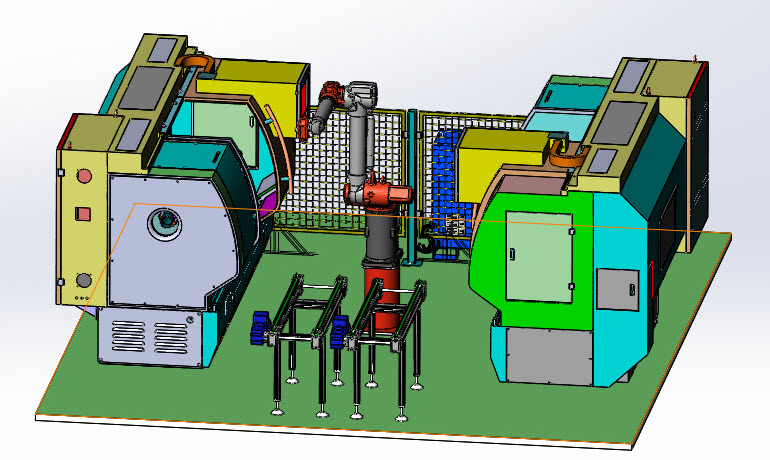

Combined with customer automation needs and production processes, CNC machine tools, robot guide rails, tooling, material racks and machine tool (including loading and unloading robots) fixtures of different uses and specifications can be selected. Various automated robotic loading solutions can be realized to improve the processing efficiency of a broad range of machines such as CNC machines, punching machines, grinders and etc.

Among them, auxiliary modules (robot rails, material racks, control cabinets, etc.), custom modules (tools, fixtures, etc.), external protection systems (fences, sensors, etc.), layout mode (one robot with two machine tools, or with three machine tools, or with multiple machine tools) can be fully customized according to the actual processing needs of customers.

According to customer needs, we provide the following conventional configurations for robotic loading and unloading of CNC machine tools. If you have special needs, we can also provide you with customized solutions.

| Items | Model | Details |

| 6-axis Loading Robot | RJR/RBR Series | / |

| CNC Machine | Standard√ | Automatic door renovation, electrical renovation required |

| Robot Gripper | Customized | Design according to the workpiece |

| Robot Base | Customized | / |

| Material Racks | Customized | Storing materials and locating materials |

| Security Fence | Standard√ | / |

| Electrical Accessories | Standard√ | Connect the devices |

| Pneumatic Accessories | Standard√ | / |

Get A Free Quote