Features of HNC848Di Closed Loop CNC Controller

- 5-32 axis control

- 17″ color LCD touch screen

- External PLC & IO module

- Support NCUC, Ethercat bus protocol

- Five simultaneously controlled axes

- Five-axis RTCP function

- Five-axis auto calibration

- Used for Five-axis machine, heavy-duty machine, lathe mill combo

- Support dual channel control (optional)

Hardware

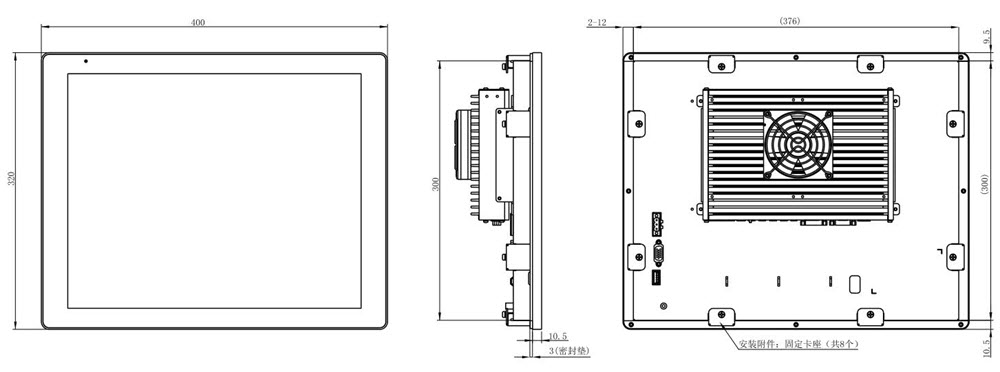

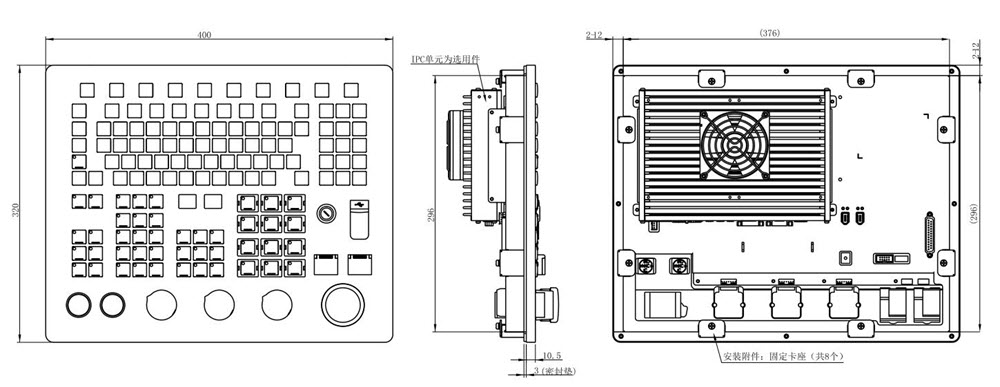

(1) Panel

Material: Aluminum alloy panel, stylish appearance.

Size: 17-inch touch screen, supports 1280*1024 high-definition resolution

Keyboards: Crystal keys, color matching according to function

Multiple functions: MCP keyboard reserves 12 customized keys to facilitate users’ individual needs.

(2) System

CPU: On board i7-5550U CORE dual Core 2.0GHz

Graphics card: Built-in Intel HD Graphics 5500 display core

USB: 8 USB, 4 USB3.0 and 4 USB2.0

Hard disk: 128G solid state drive

System memory: 8G, maximum expansion to 16G

Network: 2 LAN ports, WIFI built-in module

Software

(1) RTCP Functions

Support up to 3 linear axes + 4 rotary axis machine, covering 21 common five-axis machine tools.

It supports RTCP function, and provides two programming methods.

(2) Inclined surface machining

Establish a Tool Coordinate System (TCS) on the inclined surface and program it in this coordinate system.

(3) 3D simulation

Graphical 3D simulation function can not only perform graphic simulation of NC program before processing, but also realize graphical real-time simulation during processing.

(4) Intelligent function

Can work with intelligent APP center. APP intelligent tools related to the 5 axis CNC controller system.

Production Flow