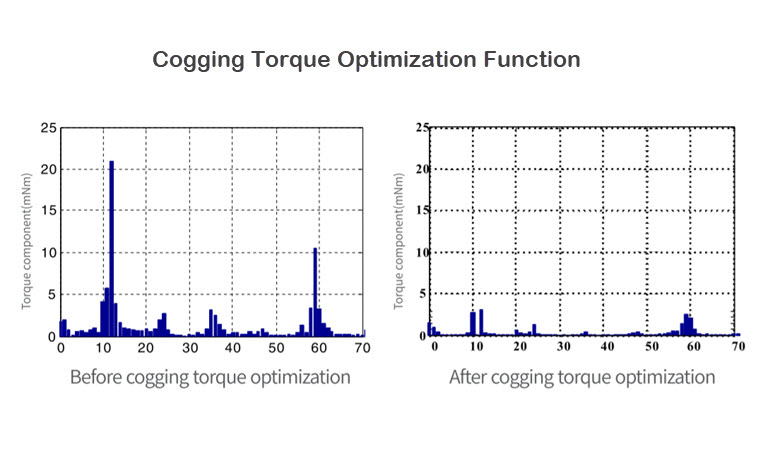

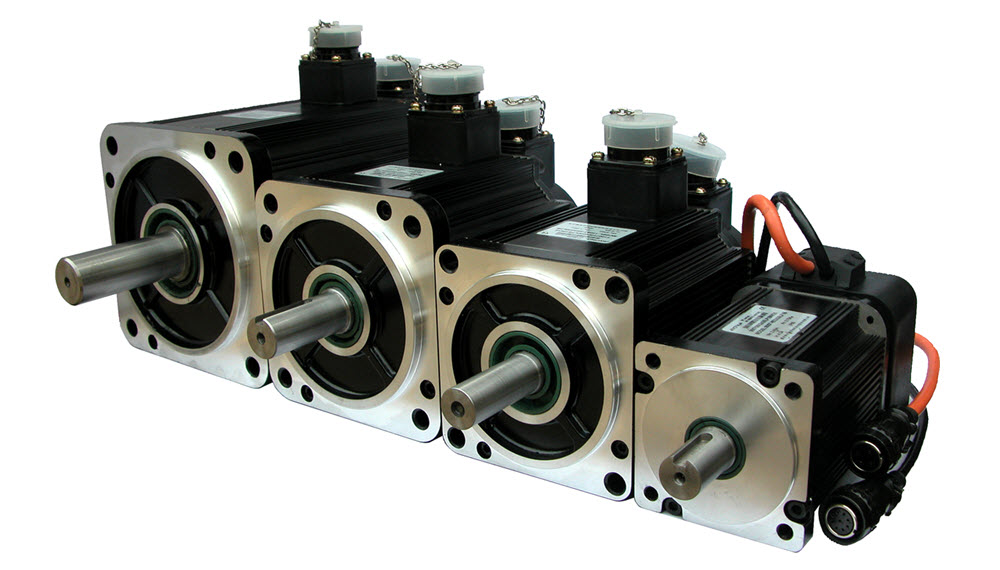

The LDD series CNC servo motors are of high stability, high resolution and high torque density. After optimized with the cogging torque function, the motors are greatly reduced in the cogging torque and torque ripple. It enhances the dynamic balance accuracy, makes the machine tool run more smoothly with reliable processing quality and decreased noise.

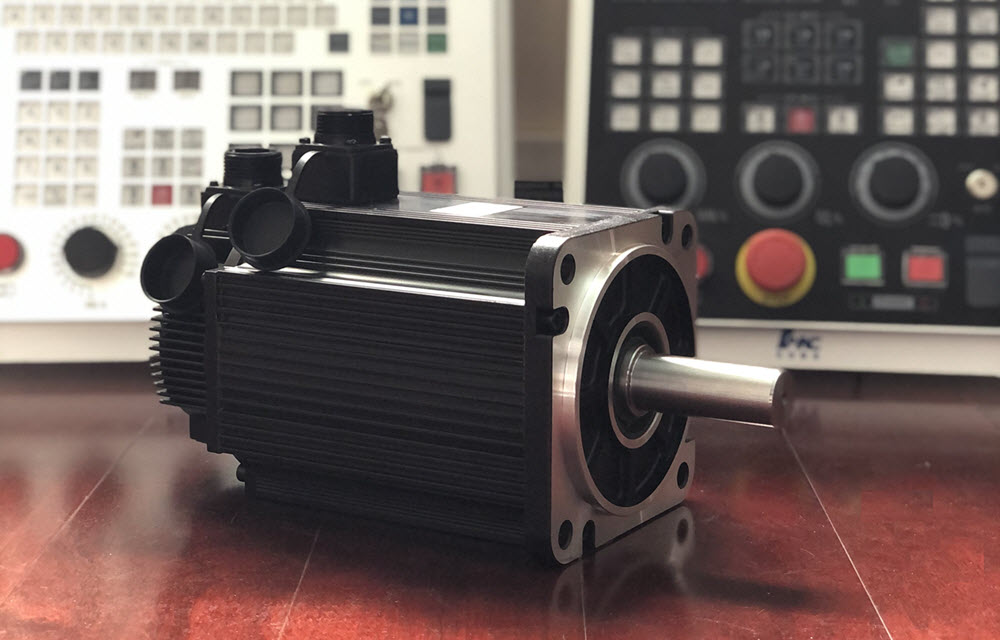

CNC Motor

Get A Free Quote

Products List

GM

HNC AC Spindle Motor for CNC

- Torque: 14-1079 Nm

- Rated speed: 500-2000rpm

- Rated power: 2.2 to 160kw

Functions & Features

The CNC motors have the advantages of advanced production technology, solid structure, optimized size, light weight, high running efficiency, energy saving, low noise and long-term trouble-free service life.

The LDD series low voltage feed motors have the characteristics of high torque density, low cogging torque, high response frequency and high stability. GK series high-voltage feed motors have the characteristics of high torque, high power, wide output range, low torque ripple, and high rotation accuracy. They can be adapted to a variety of encoders and never demagnetize. GM series high-voltage CNC spindle motors have the characteristics of high torque, fast dynamic response, energy saving, high speed and stable performance.

The CNC system which adopts the high-performance CNC motors can ensure the CNC machines run more smoothly, greatly improve the precision and finish of metal processing, and fully meet the needs of various complex metal processing such as turning, milling and grinding.