Model

Axis

Working radius

Payload

The RJR630 has further structural optimization and an advanced interpolation algorithm for the control system. Featuring the highest precision, strong acceleration, it easily handles the load and uploads, palletizing, assembly, polishing, and welding, etc.

1. Cost-effective. Low cost, it is a universal industrial robot that can be reprogrammed for other handling and assembly operations and the cost can be recovered in one year.

2. Longevity Service life. The use of high-precision and high-rigidity imported reducers can last for several decades. One investment can be beneficial for years.

3. High acceleration performance. Low-speed ratio and high-precision reducer with ultra-fast acceleration performance that the fastest acceleration time can be 0.3 seconds.

4. High integration. The built-in signal line and the air pipe of the main body are plug-and-play without complicated wiring. The internal cable is non-slipping, which can keep the trouble-free rate for a long time.

5. Ultra-high precision. In addition to the precise design, the imported high-precision reducer is used. The re-positioning accuracy of the end part is up to ±0.05 mm.

6. High smoothness. The advanced control system and the servo drive system are used to achieve high-speed and smooth motion performance, and the transition point is an almost zero-time pause.

7. High rigidity. After structural optimization, high-power motors and high-quality materials are used to achieve good rigidity.

8. High load capacity. The maximum load of 30 kg at the end part can easily handle the application in the load and uploads, processing, assembly, and welding industries.

| Material handling robot | RJR620(L) | |

| Degree of freedom | 6 | |

| Payload | 30Kg | |

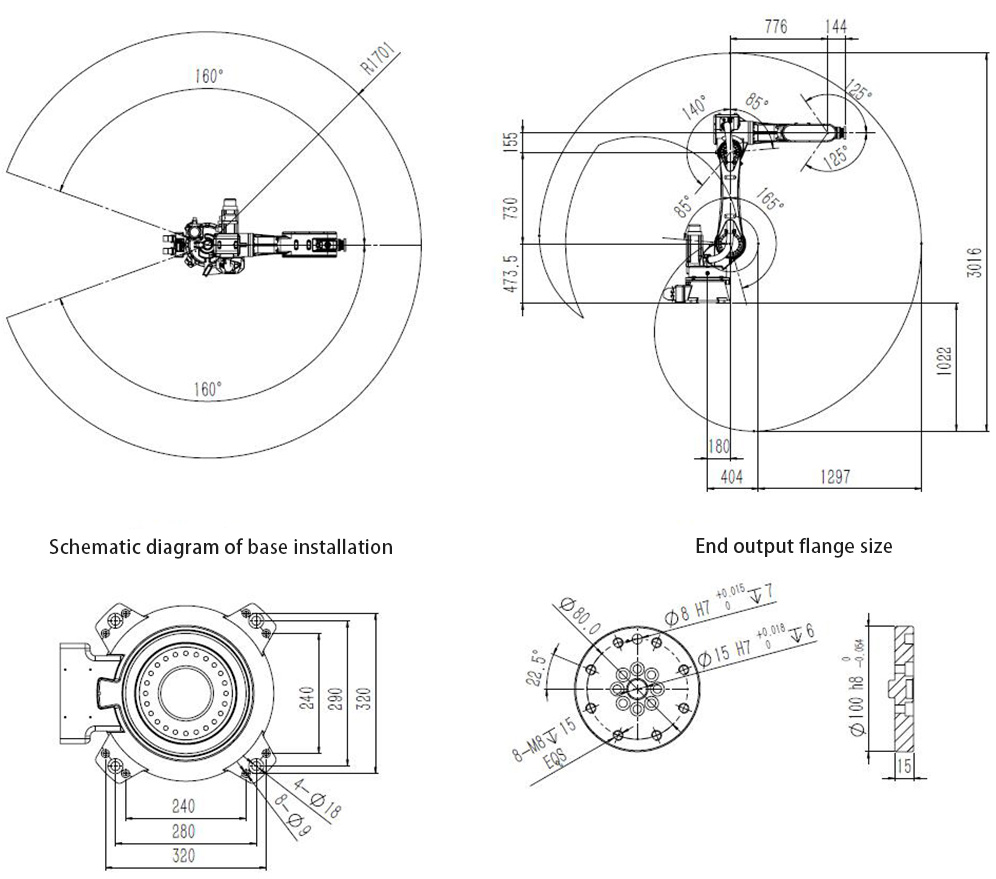

| Maximum working radius | 1701mm | |

| Repeated precision | ±0.05 mm | |

| Range of motion | J1 | ±160° |

| J2 | -175°/+75° | |

| J3 | +40°/265° | |

| J4 | ±180° | |

| J5 | ±125° | |

| J6 | ±360° | |

| Rated speed |

J1 |

99°/s,1.73rad/s |

| J2 | 87°/s, 1.52rad/s | |

| J3 | 144°/s,2.51rad/s | |

| J4 | 180°/s,3.14rad/s | |

| J5 | 180°/s,3.14rad/s | |

| J6 | 225°/s,3.92rad/s | |

| Maximum speed |

J1 |

148°/s,2.59rad/s |

| J2 | 109°/s,1.9rad/s | |

| J3 | 172°/s,3.01rad/s | |

| J4 | 300°/s,5.23rad/s | |

| J5 | 300°/s,5.23rad/s | |

| J6 | 375°/s,6.54rad/s | |

|

Allowable moment of inertia |

J6 |

0.8kg㎡ |

| J5 | 3.3kg㎡ | |

| J4 | 8.7kg㎡ | |

| Allowable torque | J6 | 30.7Nm |

| J5 | 73.4Nm | |

| J4 | 140.4Nm | |

| Applicable environment | Temperature | 0~45° |

| Humidity | 20%~80% | |

| Others | Avoid contact with flammable, explosive or corrosive gases and liquids. Keep away from electronic noise sources (plasma). | |

| Cable Length of Instructor | 8metre | |

| Body-cabinet connection length | 6metre | |

| I/O parameters | Digital: 32 inputs, 31 outputs (one for control cabinet fault indicator output) | |

| Battery capacity | 5.6kVA | |

| Rated power | 4.5kW | |

| Rated voltage | 3-phase AC380V | |

| Rated current | 8.1A | |

| Body protection grade | IP54 | |

| Installation method | Ground installation, upside down installation | |

| Body weight | 305kg | |

| Control cabinet protection grade | IP53 | |

| Control cabinet size | 750mm(wide)×486mm(thick)×1030mm(high)-vertical | |

| Control cabinet weight | 186KG | |

In the history of more than 30 years of development, it has won many awards and more than 1,000 patent certifications.