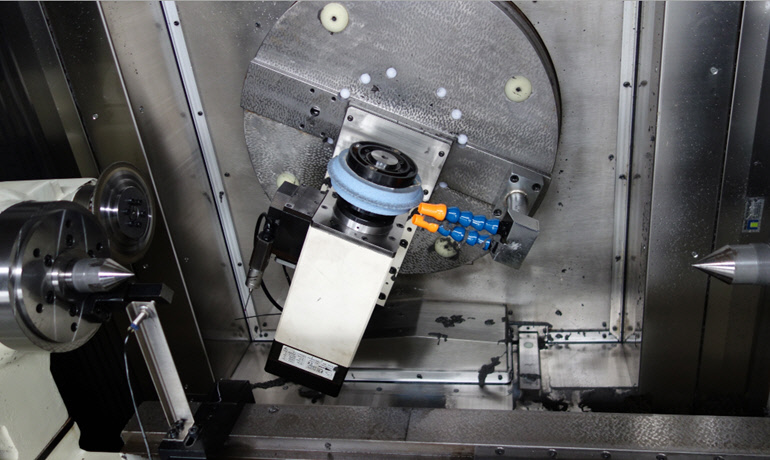

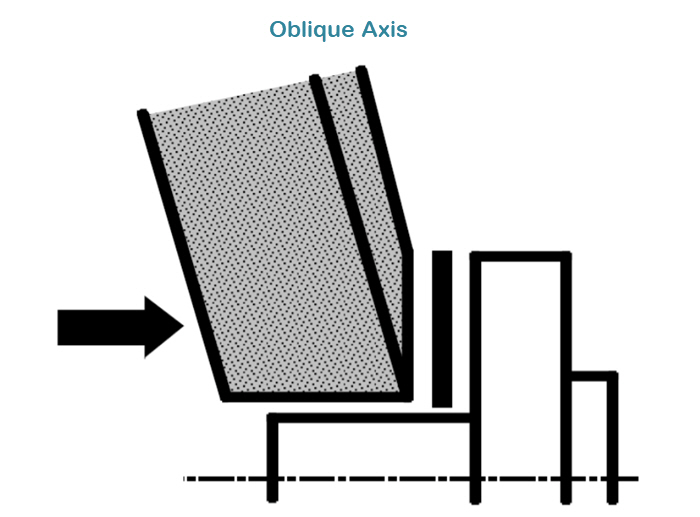

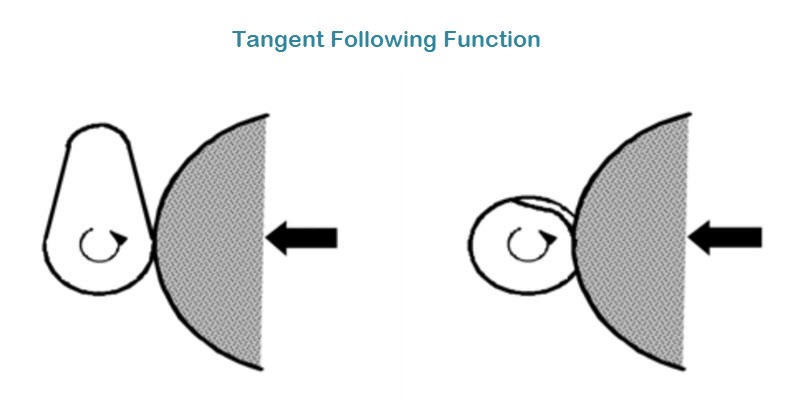

HNC-8 series CNC grinder controller has a variety of advanced functions, such as oblique axis, electronic gear box, video-assisted tool setting, tangent point following, etc., which can effectively ensure the efficient and precise grinding of various workpieces such as outer circle, inner circle, end face, gear hobbing, helical teeth, arc teeth, eccentric circles, non-circular surfaces, etc.

CNC Grinding Machine Controller

HNC-8 series CNC grinder controller is specially designed in line with the application requirements of cylindrical grinding, surface grinding and etc.

According to the contour shape of the workpiece and the actual processing requirements, the HNC-8 series CNC grinding machine controller can use advanced and professional CNC technology, algorithms and grinding processes to realize high-efficiency and high-accuracy control to various CNC grinding machines such as surface grinders, cylindrical grinders, internal grinders, centerless grinders, thread grinders and etc.

Get A Free Quote

Products List

HNC-808DG

HNC-808DG Open Source Grinding CNC Controller

- Axis: 2-4 axes

- Protocol: NCUC, M3, Ethercat

- Screen: 10.4 inches

Features & Functions

According to the diversified grinding requirements, the HNC-8 series grinding machine CNC system is developed with graphical programming functions and grinding process modules that it allows the operators to achieve simple programming without professional knowledge.

Our CNC grinder controller system integrates various process module packages, such as non-vibration plunge grinding, pass grinding, multiple plunge pass grinding, gauge tool setting, grinding wheel repair and other functions, and also provides a secondary development platform to meet the diversified customization needs of customers.