HuazhongCNC Industrial Robot and CNC Controller Applied on Intelligent Mold Production Line

Mold is an important basic process equipment of manufacturing industry, mainly used for high-efficiency mass production of related parts and components in industrial products, and is an important part of equipment manufacturing industry. Today we will share with you the successful application cases of HuazhongCNC industrial production robots and CNC machine controller systems in the smart mold manufacturing industry.

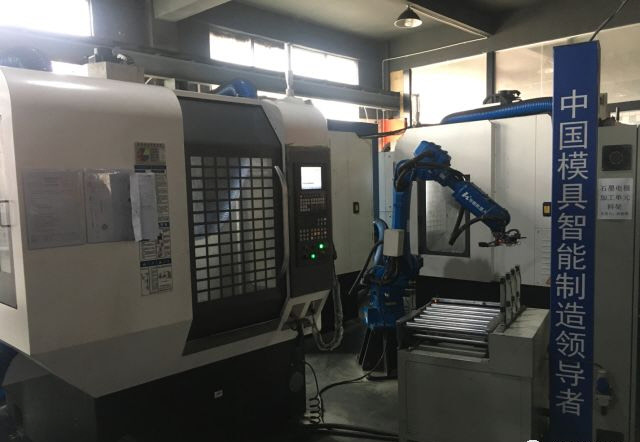

Intelligent mold manufacturing workshop

Introduction About Our Customer

Guangdong Longkai Co., Ltd. is located in Dongguan City, Guangdong Province. It is a professional supplier of comprehensive solutions in the field of plastic molds and mold intelligent manufacturing. The company has the world’s advanced intelligent mold production workshop, precision machining workshop, mold design center, project management center, quality inspection center, after-sales service center, etc. It has more 100 sets of German and Japanese high-speed machining centers, spark machines, precision grinders and etc. It is focusing on the development, design and manufacturing of mold products for different fields such as automobiles, household appliances, electronics, babies and children, and precision plastics.

HuazhongCNC industrial robots and CNC controller used in mold manufacturing workshop

Steel CNC processing center equipped with HNC 8 series CNC system

Cooperation Between Longkai and HuazhongCNC

Since 2015, HuazhongCNC and Longkai have jointly built an intelligent mold manufacturing production line based on the characteristics of the mold industry. The intelligent factory mainly includes a hardware integration solution and a software integration solution. The hardware integration scheme is divided into electrode processing area, steel material processing area, EDM processing area, three-coordinate detection system and intelligent logistics system. Software integration solutions include intelligent scheduling system, intelligent execution system, intelligent control system and intelligent decision-making system.

HuazhongCNC engineers are debugging CNC machine tool on site

Technical Characteristics of Longkai Mould Intelligent Production Lines

The collaborative work of equipment and robots is the first in the industry to realize the intelligence of mold manufacturing; the intelligent production line software solution in the field of mold processing aims to realize the intelligent production line “real-virtual integration, design and manufacturing integration, process management and control integration, and production and collaboration integration”. It integrates production and resources to establish core competitive advantages, and ultimately achieves rapid response, high quality, and low cost in manufacturing. By building a distributed collaborative manufacturing service system platform based on the enterprise’s private cloud, customers can rely on the cloud platform and big data center to develop value software and process expert systems for the mold industry to enhance the competitiveness of the enterprise.

Molds processed by intelligent mold production lines

Significances of Adopting Mold Smart Production Lines

After the introduction of the mold intelligent production line, the big data management center is used to realize intelligent production scheduling, automatic mold generation, automatic binding of program information to the machine, automatic detection, automatic feedback, automatic repair and compensation, and automatic material distribution. It realizes the intelligent production of the whole process from raw materials to finished, which not only reduces dependence on personnel, but also achieves controllable and traceable product quality.

In this successful application case, the processing speed of the high-speed drilling and tapping center equipped with HNC 8 series CNC mill controller is 10-20% faster than that of well-known overseas systems. It has achieved original transcendence in intelligent technology and large-scale applications in the field of intelligent mold manufacturing.