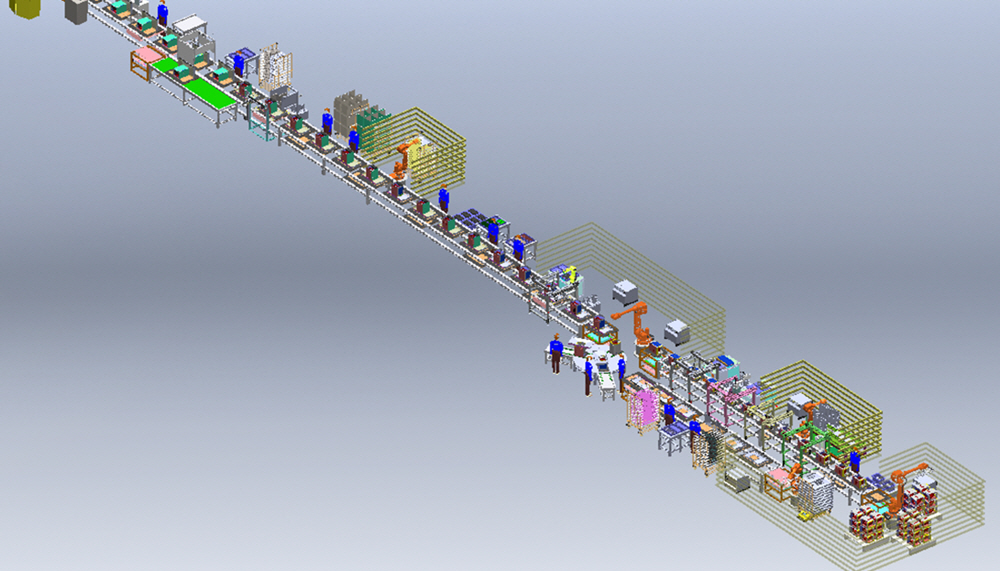

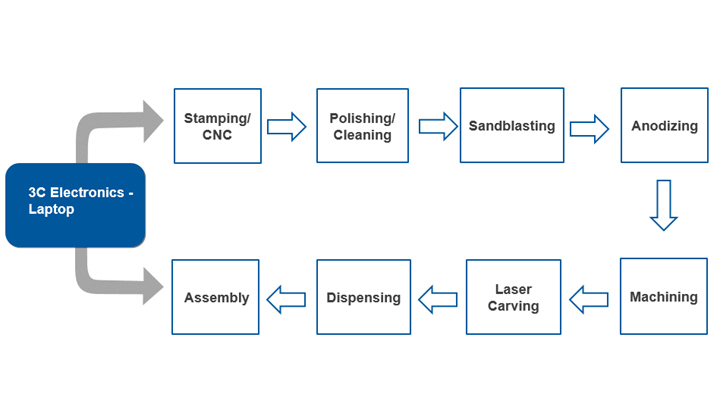

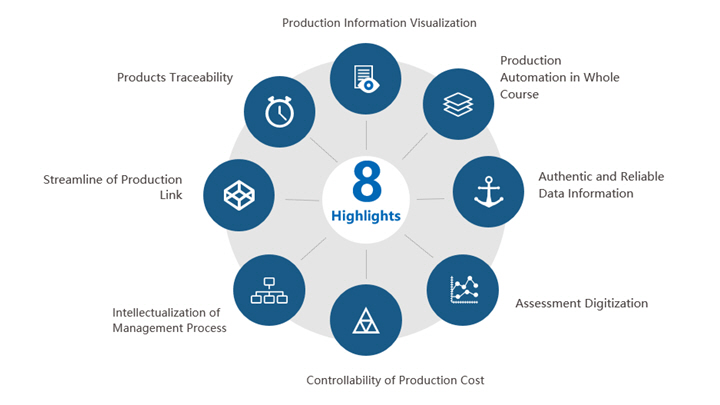

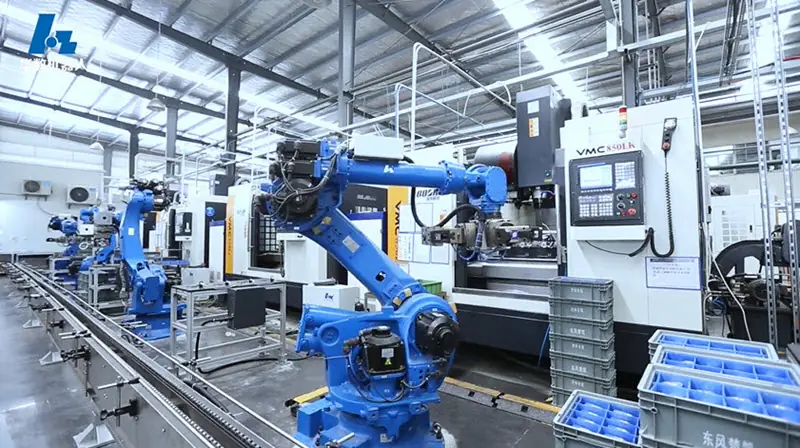

Automated assembly line or robotic assembly line is indispensable in industrial manufacturing, and its application fields are getting wider and wider. After the HNC series automated assembly line robotic arms are configured with advanced algorithms, workers and robots can be organically combined to establish a division of labor and operate in the automated assembly system, which can meet the assembly requirements of various products, thereby reducing product manufacturing cycles. Our robotic assembly lines have been successfully applied in many fields such as home appliances, kitchen & bathroom, 3C electronics, etc.

Offer You The Best Service

Get A Free Quote