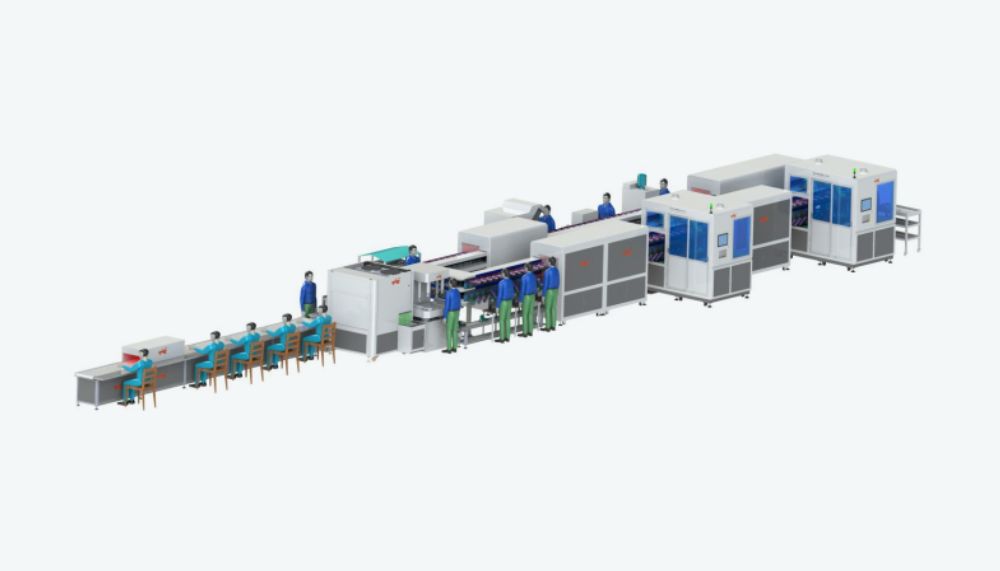

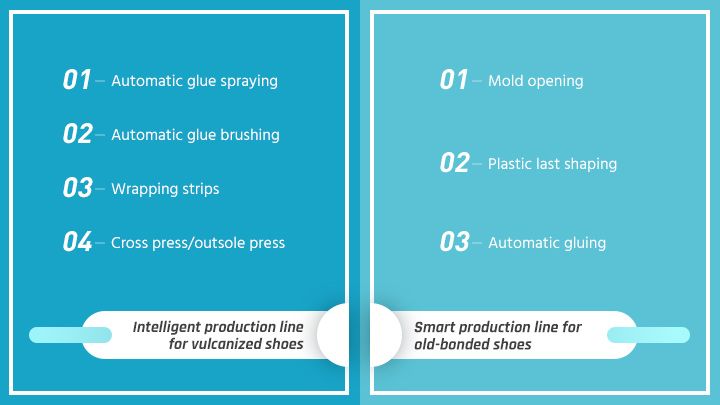

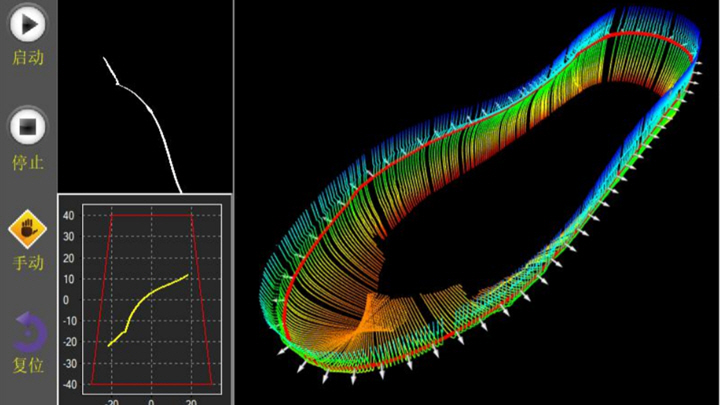

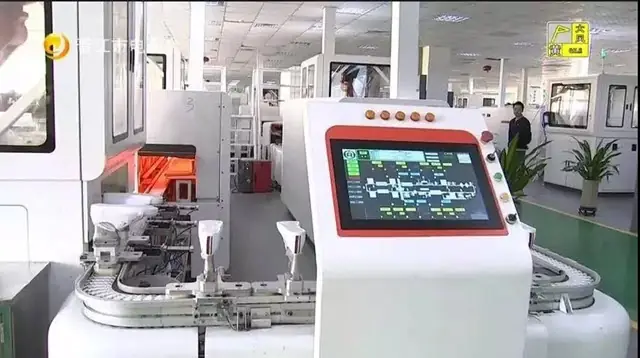

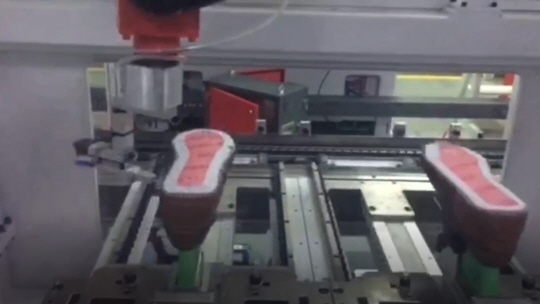

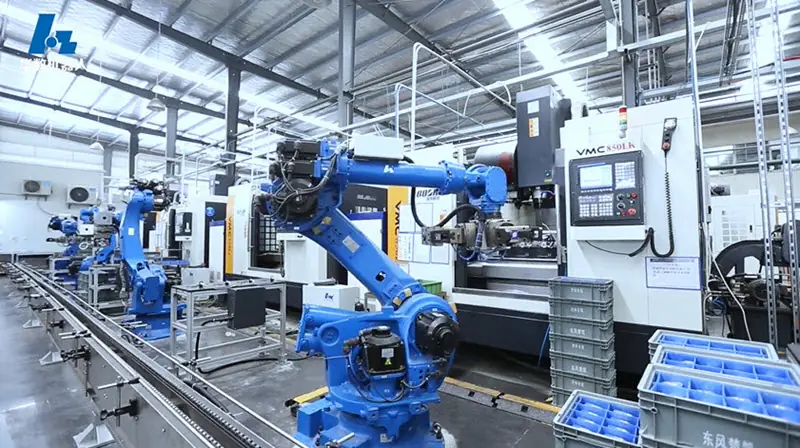

The shoe-making production line is a whole-industry-chain intelligent equipment system specially developed by HuazhongCNC for shoe-making enterprises, aiming to create a flexible and intelligent shoe-making production line. The smart shoe production line integrates robots, robotic 3D vision systems, big data and artificial intelligence technologies.

It empowers the transformation and upgrading of the traditional shoemaking industry with intelligent manufacturing, improves the level of production automation, reduces production costs, and improves production efficiency and product quality for the traditional shoemaking industry, and realizes a human-machine collaborative shoe forming automated production line.