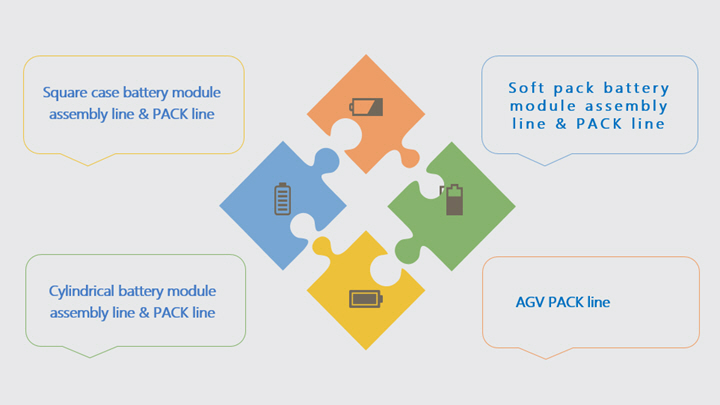

HuazhongCNC lithium battery assembly lines are divided into four categories, square shell battery module assembly line, soft pack battery module assembly line, cylindrical battery module assembly line, and AGV PACK line.

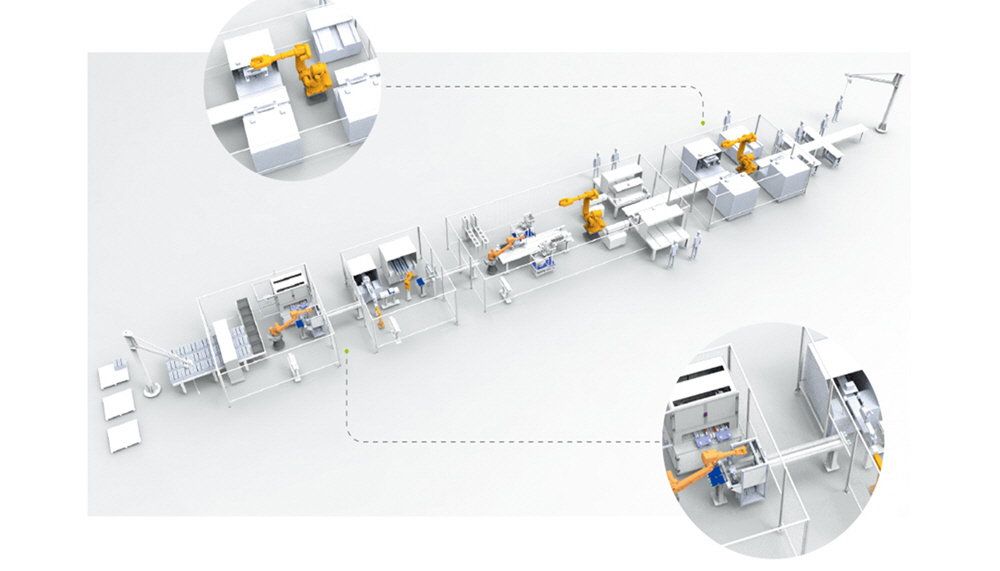

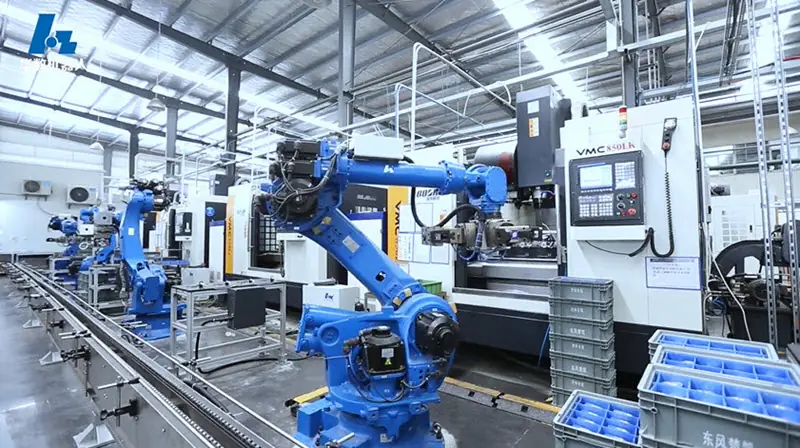

Based on intelligent robots and information-based manufacturing technology, the lithium battery production line can realize flexible and intelligent production. The whole process adopts the information acquisition module to monitor the entire production line, and the central control system controls the entire production process. The production process adopts robot instead of manual production, and very few stations are set up with manual intervention, and the degree of automation is high.