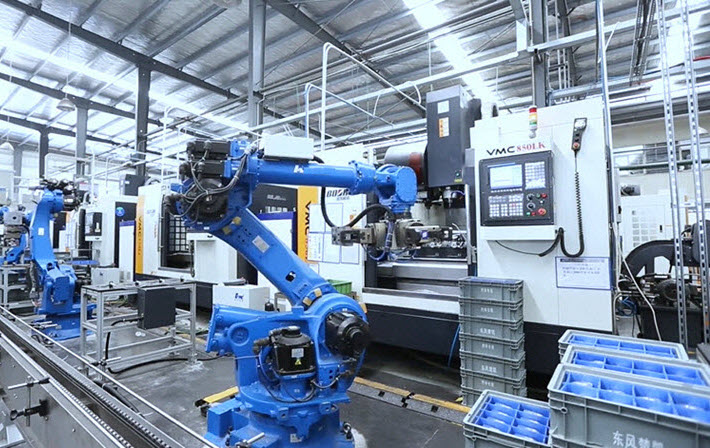

Robotic Production Line for Key Automotive Parts Processing

Industrial robots provide excellent opportunities for modern high-speed car production. Through tailor-made robot production lines, the quality and productivity of automotive parts production and assembly can be improved. This can not only enhance the work process of the entire automotive industry, but also make the production of automotive products more efficient and safer, and improve the competitiveness of companies in the automotive field. In this article, we will share a successful application case of HuazhongCNC robotic production lines in the automotive parts processing.

Basic Introduction of the Project

This project is a demonstration application of automated production line control systems and industrial robots for the processing of key automotive parts. The robotic production line is composed of machine tools, CNC systems, HuazhongCNC industrial robots, and industrial software with independent intellectual property rights. The functions and performances of the used CNC machine tools, robots, CNC systems, and functional components have been comprehensively verified and improved, and the overall process solution capabilities have been enhanced.

Technical Features

The project combines the specific needs of automotive high-pressure oil pump drive unit and wheel hub processing. According to its structural and technological characteristics, the main research and application objects are CNC machining centers, turning centers, CNC grinders and robots. It carried out research on the reliability technology, real-time monitoring technology, process processing technology, intelligent and automation and other adaptable key technologies of the equipment related to the complete solution of the robot production line, realized the practical application in the processing of key automobile parts and components, and played a good exemplary role for market promotion.

1. A total of four automation units are set up, namely the camshaft hot front automatic line, the shell automatic line, the PF2 flange automatic line and the hub flange automatic line.

2. Each automatic production line is equipped with HNC series CNC system and HNC series industrial robot (including servo driver, motor, reducer and etc.).

3. A digital management platform for robotic production line applications has been established to realize the dynamic information collection of processing equipment and robots, the networked and informatized management of the production process, and the interconnection with the workshop management system.

4. The reliability design, growth technology research and evaluation of the numerical control system have been completed. Before the completed numerical control system is delivered to the user, the system manufacturer shall conduct a simulated actual operating condition operation test and write a test report.

Results of the Robotic Production Line Project

With the completion of this project, we have gained a lot of meaningful results:

1. Promoted the in-depth development of HuazhongCNC 8 series CNC system, and promoted the construction of its network, information and intelligent platform.

2. Developed the robot loading and unloading fixture control technology for the production line of key auto parts.

3. Completed the adaptive technology research of the servo drive controller, servo motor and reducer; completed the main structure, stiffness & accuracy stability analysis and optimization design of the robot for the automobile hub unit and high pressure oil pump drive unit; completed the trial production, verification and improvement of two prototypes in the flexible automatic processing production line of the automobile wheel hub unit and the high-pressure oil pump drive unit; completed the application research of special robot loading and unloading fixture for automobile wheel hub unit and high pressure oil pump drive unit.

The robot production line has been successfully operated for more than one year. The overall efficiency of the factory’s production line equipment has been significantly improved, and the parts have good consistency. The relevant staff can understand the operating rate of the production line equipment in real time and grasp the status of each equipment in time. In addition, this project has completed the construction of a demonstration application base for high-pressure oil pump drive units, a hub and hub unit production line demonstration application base, and a digital management platform demonstration application base, which has promoted the demonstration and application of key technological achievements in automobile key parts manufacturing enterprises. And it confirmed that China’s CNC machine tools and CNC systems meet the needs of key automobile parts manufacturing enterprises, and have contributed to the technological innovation of key automobile parts.