Types of VMC Machine, Tips of Choosing VMC Machine

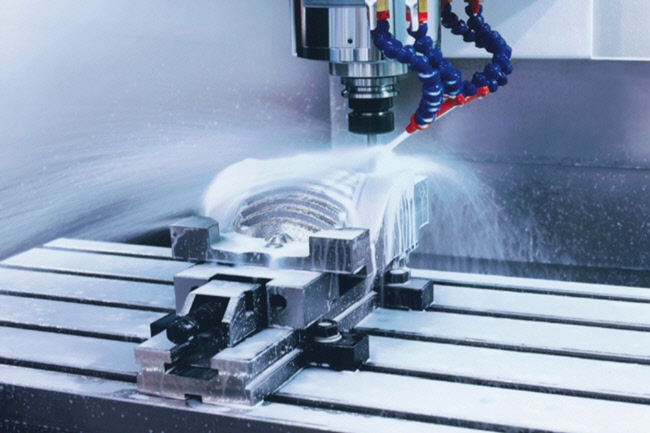

VMC, abbreviated from Vertical machining center, refers to a machining center where the axis of the main shaft is perpendicular to the worktable. It is mainly suitable for processing complex parts such as plates, plates, molds and small shells. The vertical machining center can complete processes such as milling, boring, drilling, tapping and cutting threads. However, do you know what are the types of VMC? In this post, let’s discuss the types of vertical machining centers and tips upon selecting a suitable vertical machining center.

What Are the Types of VMC Machine?

1. Classification According to the Guide Rail – Hard Rail & Linear Rail

According to the form of the guide rail of each axis, the VMC machine can be divided into hard rail and linear rail. The hard rail has good rigidity and is suitable for heavy cutting. The linear rail is ball-bearing guide rail, which has a fast speed and a more sensitive movement.

2. Classification According to the Spindle Speed – Low Speed & High Speed

The spindle speed of the low-speed type VMC machine is 6000-15000rpm, and the spindle speed of high-speed type is above 18000rpm. The high-speed and high-precision VMC machines will have higher surface finish and higher processing precision. Of course, the torque of the spindle will be lower when the speed is high; the torque of ordinary low speed will be higher, and it is suitable for milling and drilling deep holes.

3. Classification According to the Bed Structure – C Type & Gantry Type

According to the bed structure of the VMC, it can be divided into C type and gantry type.

4. Classification According to the Column Structure – Fixed Column & Moving Column

(1) Fixed-column VMC, also known as table movement vertical machining center. The production and sales of this type of vertical machining center account for about 75% of the vertical machining center market, and most machine tool manufacturers have this type of VMC machines such as VMC850, VMC1160 and etc. This type of VMC has the following advantages: Low cost, easy design and manufacturing. Easy to realize mass production. Compared with the movable column VMC: the fixed-column type VMC has high rigidity of the column parts and headstock parts; during the cutting process, the headstock vibration of components is small.

2) Moving-column type VMC machine, it is also known as fixed worktable VMC. The production and sales of this type of vertical machining center account for about 15% of the vertical machining center market. This type of VMC machine is a mid-range vertical machining center with the following advantages: it can be optimized for the inertia of each axis; it effectively avoids the problem of overshoot in response to overshoot when the load weight is small, and slow response when the load weight is large, and it avoids the problems caused by the above problems. The biggest advantage is that this type of VMC machine can process heavy workpieces. Larger workpieces and special-shaped workpieces can be placed on the worktable, and high-precision machining can be smoothly achieved for parts with an incorrect center of gravity. The fixed workbench makes it easier for the operator to approach, the operation of loading and unloading the workpiece is easier and labor-saving, and the pleasantness of the operation is greatly improved.

How to Choose a VMC Machine of Suitable Type and Specifications?

Choosing a high-efficiency VMC has a vital impact on the efficiency of workpiece processing and production efficiency. Let us take a look at the main points of choosing a suitable VMC machine:

1. Determine the Machine Specifications:

Please select the size of the worktable of the machine tool and the stroke of the three linear coordinate systems according to the size of the workpiece to be processed. The size of the worktable must be large enough that the workpiece can be smoothly clamped on it, and the processing size must be within the stroke of each coordinate. In addition, the limitation of the tool change space and the interference area of each coordinate must be considered.

2. Determine the Accuracy of the VMC Machine:

We should select the VMC machine of the corresponding accuracy level according to the machining accuracy requirements of the workpiece. The accuracy of the VMC directly determines the yield of processing. High-precision VMC plays a very important role in reducing defective products and reducing production material loss. The accuracy of VMC machine is an important index to measure the performance.

3. Determine the Capacity of the Tool Magazine:

There are two types of tool magazines: hat type tool magazine and disc type tool magazine. For machining center manufacturers, a VMC machine of the same specification usually has 2 to 3 tool magazines with different capacities. When selecting the capacity of the tool magazine, we should determine the required quantity according to the process analysis result of the workpiece to be processed. The number of tools required for a part in a clamping is required to determine the capacity of the tool magazine.

4. Determine the Configuration of VMC Machine:

The VMC CNC controller brand, guide rail (whether it is a linear rail or a hard rail, this is selected according to the workpiece processed by us. Usually, the product processing uses the linear rail, and the mold processing uses the hard rail), spindle drive mode (belt drive, direct drive, electric spindle), etc. These configurations must be understood clearly in order to correctly select the appropriate VMC.

5. Choose a Reliable Manufacturer

After determining the technical grade and basic structure of the VMC, the next step is to focus on the manufacturer’s technical services. It is recommended to choose a manufacturer with strong after-sales service capabilities and a larger scale.

The above are the types of VMC machine and the important key points for choosing a VMC. I hope this article can help friends who want to buy a VMC machine. If you want to buy a cost-effective, high-performance machining center, you may wish to consider INC-MT which provides high-performance vertical and horizontal machining centers adopting advanced Taiwanese technology. If necessary, please contact us and we will serve you wholeheartedly.