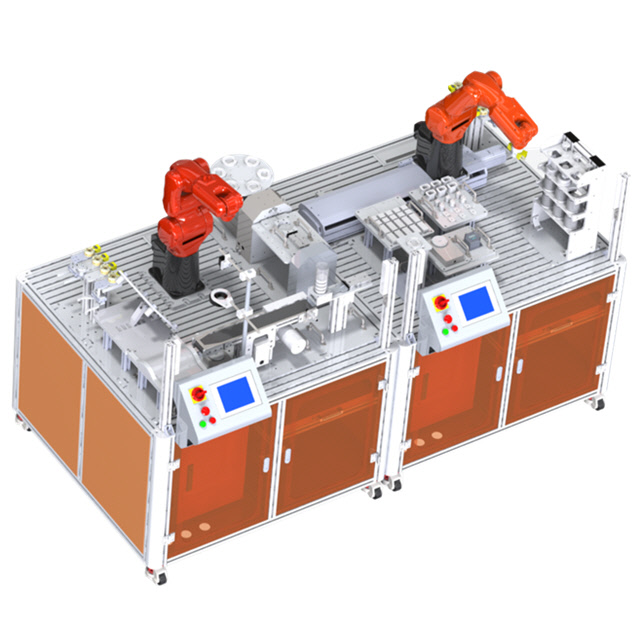

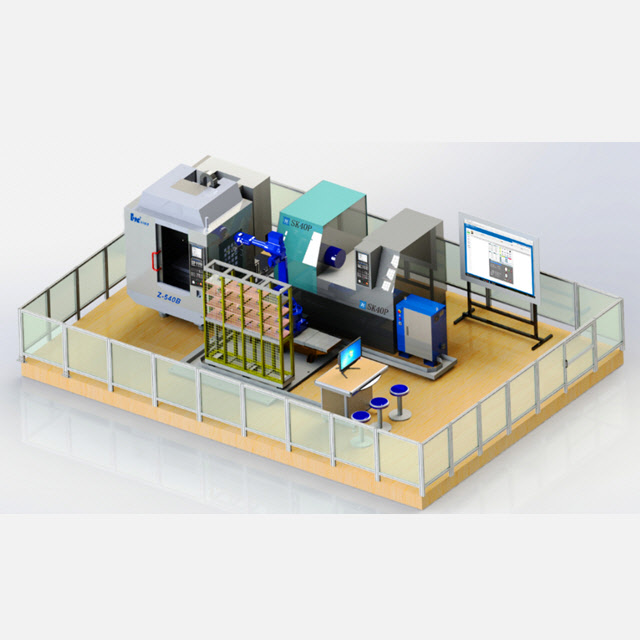

1. Adopt mechatronics symmetrical structure, optimize the internal reinforcement through finite element analysis, and improve the resistance to bending and torsion.

2. The bed of the 5-axis CNC machining center adopts a typical box frame structure, the overall structure is stable and the rigid.

3. The use of high-rigid casting iron materials, after heat treatment, it can eliminate the casting internal stress to have better accuracy retention.

4. All linear axes adopt high-rigidity roller guides, and the balls are designed with screw transmission structure.

5. The high-torque motor drives the B axis (pitch) and C axis (rotation) to rotate, the transmission chain is very short, “zero” backlash, and good rigidity. High-precision angle encoder performs feedback to achieve accurate positioning.

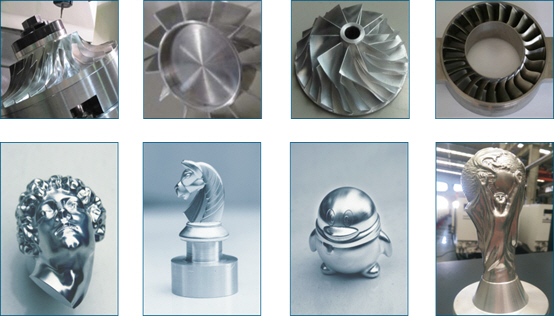

6. The five-axis VMC machine has the characteristics of high dynamics, high rigidity, high power and powerful cutting.