Application cases of HuazhongCNC supporting all-round small five-axis

As a representative of high-grade CNC technology, the Five-axis linkage can process mechanical parts with complex surfaces. Especially in solving aircraft impellers, blades, marine propellers, large diesel engine crankshafts, and other aspects with unique advantages.

Traditional five-axis CNC technology and five-axis CNC machine tools

1, Expensive, difficult to reach

In recent years, five-axis CNC machining centers have been more and more widely used in various fields. In practice, processing shaped and complex parts, five-axis linkage technology is undoubtedly the most effective means to solve the problem. The core components of traditional heavy five-axis equipment are the double pendulum milling head, and the double rotary table, expensive. In addition, compared to the three-axis machine, five-axis machine bed castings are to be processed in more places. The difficulty is also large, water, electricity, oil, gas, and other accessories, the cost is also high.

2, Focus area dedicated

Five-axis machine tool is a landmark of CNC machine tool manufacturing technology. It is the most difficult technology in CNC technology. Traditional five-axis machine tools are mainly used in the complex surface of efficient, precise, automated processing. And it is the key processing equipment in key areas such as shipping, aerospace, and high-precision instruments. In ordinary civilian areas, it is difficult to see the five-axis machine tool figure.

3, Complex operation

Five-axis linkage processing parts itself is complex. Processing personnel must be more familiar with the operation of the machine tool, familiar with the operating system, have a better understanding of processing, and also special software to compile the program. In addition, the processing program is complex and relatively large, and the part’s processing time is extended.

All-in-one with HuazhongCNC system, Small five-axis with amazing grace

HuazhongCNC has accumulated rich experience in five-axis simultaneous machining in various key fields over the years. Supporting full-featured small five-axis machine tools will rewrite the traditional impression of five-axis machine tools.

All-in-one five-axis <<<<

Industrial grade machining center should be the tool magazine, cooling water circulation for this machine is standard. Tool setting instrument and probe is optional. The machine is small, but also maintains heavy cutting characteristics: it can process steel parts. The machine tools on the market use micro-level rotors and DD motor baskets in batches. That it can only process non-ferrous metals such as gold, silver, copper, and aluminum, ABS engineering plastics, and even wood.

Efficient five-axis <<<<

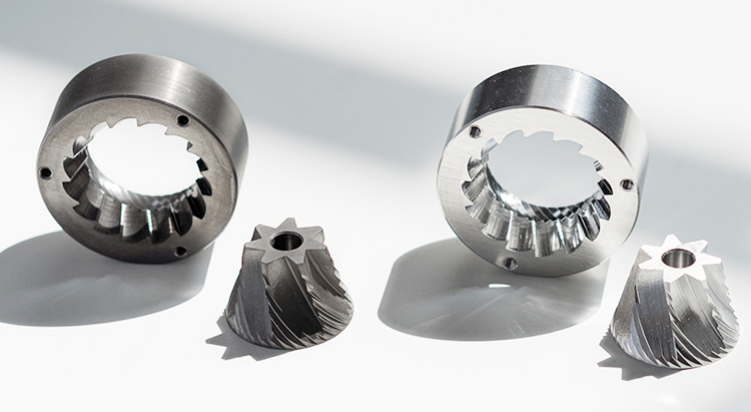

Taking this impeller F55V test part of the 3.0T turbocharger as an example. 7 large and 7 small blades with a diameter of 70 mm, machining completed in 7 minutes and 11 seconds,

Cost-effective five-axis <<<<

Adopt the gantry frame structure, stretch the left column of the gantry into a wall, and install the Y-axis moving parts (screw, line rail) on this wall perpendicular to the ground. This can create a cost-effective five-axis. Because it ensures the space and rigidity requirements while reducing the weight and size of the machine.

HuazhongCNC five-axis system’s High speed and high precision technology

Highlight 1: 5-axis RTCP function

The RTCP function of a 5-axis data machine can be interpreted as a rotation around the tool center point function. In 5-axis CNC machining, the RTCP function is particularly important. Due to the presence of rotating axes, which can effectively reduce non-linear errors during machining. Machining flexibility is a more intuitive advantage. With RTCP technology, the operator does not have to align the workpiece precisely with the axis of the rotary table. And the machine automatically compensates for the offset, which greatly reduces auxiliary time and improves machining accuracy.

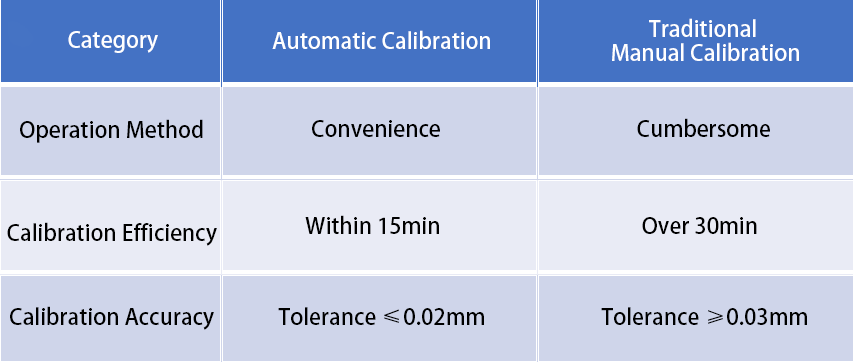

Highlight 2: Fast auto-calibration technology

- Interface-based input of machine structure, travel speed, probe data, and other parameters

- Direct reading of the teaching points for easy operation

- Recording of the measurement position for higher accuracy

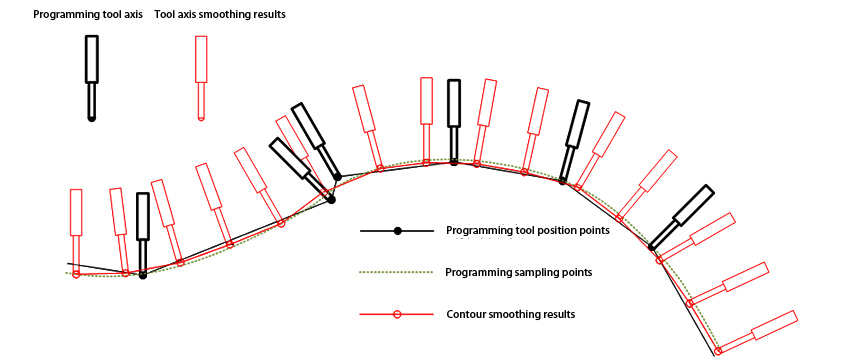

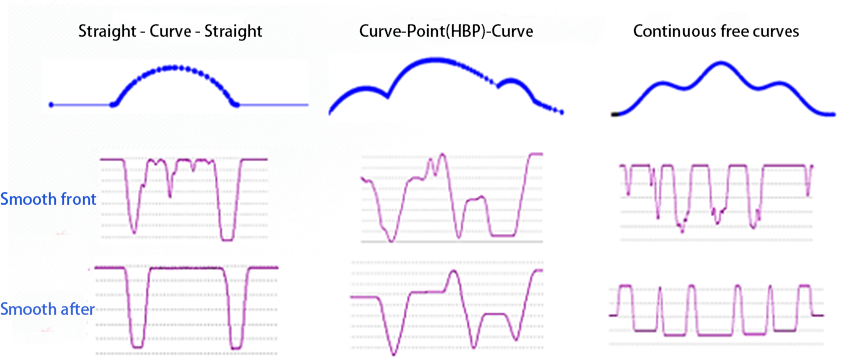

Highlight 3: High speed, precision, and efficient machining technology

A number of machining technologies have been developed to improve precision, quality, and efficiency. These include small line segment forward technology, path smoothing, noise filtering, intelligent surface, flexible acceleration, and deceleration. It also has high-speed rigid tapping, intelligent overlap, adaptive feeding, synchronous double probe machining, and speed feed compensation.

Highlight 4: 5-axis workpiece measurement

- Workpiece measurement—interface-based operation, multi-scene applications

- Different interfaces: measurement cycle interface, calibration interface, the measurement configuration interface

- Three ways: manual measurement, insertion measurement, and automatic measurement, 15 types of measurement features are used singly or in combination to correct the coordinate system and correct the errors generated during the machining process

- Application range: tool setting, coordinate system tool complement adjustment, dimensional measurement

- High accuracy: fast response of high-speed IO, no manual operation error

Highlight 5: CAM and post-processing

- A Thousand machines intelligent Ultra CAM: independent and controllable impeller, leaf disc special CAM software

- Universal CAM post module: provide UG, Catia, CAXA, Power Mill, and Master CAM post modules to provide universal CAM software post-processing module and the integration of multi-axis process and system

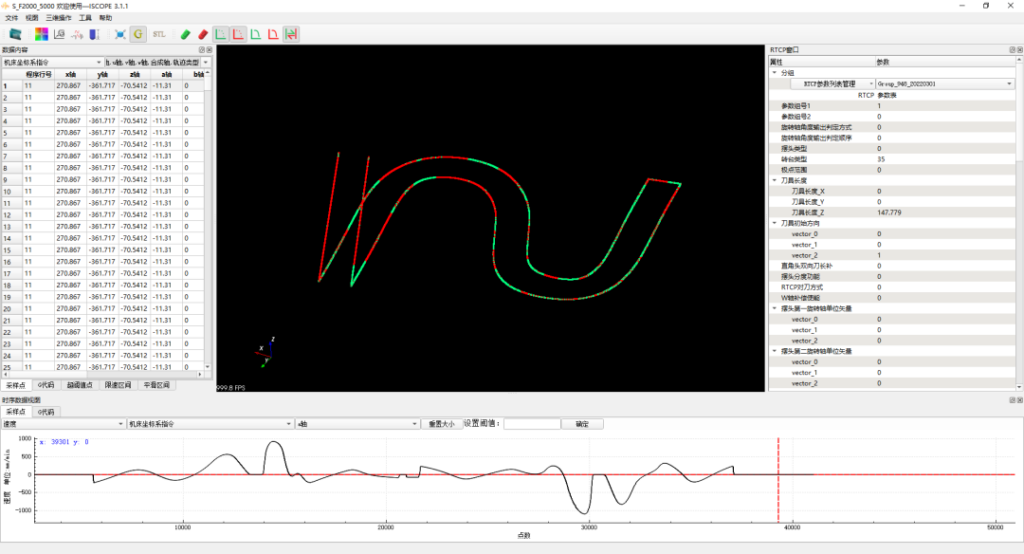

Highlight 6: Debugging and analysis tools

Through real-time data sampling and combined with RTCP parameters, 3D position visualization, 3D chromatograms, data charts, and other functions of command data and actual data are realized. It facilitates the analysis and evaluation of the linkage performance of the system. And it is effectively used for the analysis and optimization of the machining process.

A broad market for all-around small five-axis

The standard of living is improving with the production process. More and more people in society are willing to pay for high quality. In order to improve product quality, more kitchen utensils, high-end bathrooms, toys, and decorations have adopted complex surface designs. These four-axis machines cannot be processed, and only five-axis equipment can be used.

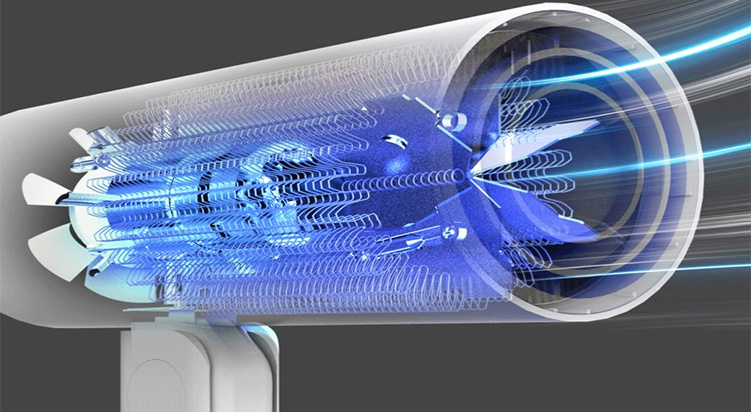

High-speed hair dryers, for example, its speed is generally higher than 100,000 rpm, in order to achieve high speed, the accuracy of the motor will need to improve nearly 100 times. In addition, most blowers’ impeller blades are overlapping each other’s structure, manufacturing difficulties, and higher costs. The small five-axis with HuazhongCNC system is the perfect solution for such needs.

Shortening the process chain and reducing machines, fixtures, shop floor space, and equipment maintenance costs are also reduced. This means more efficient and higher-quality machining with less fixturing, less plant space, and less maintenance!

Market upgrading never stops, and the pursuit of machining efficiency and precision never stops. HuazhongCNC will continue to boost the dream of the high-end manufacturing industry.