What Are the Differences Between CNC HMC and VMC

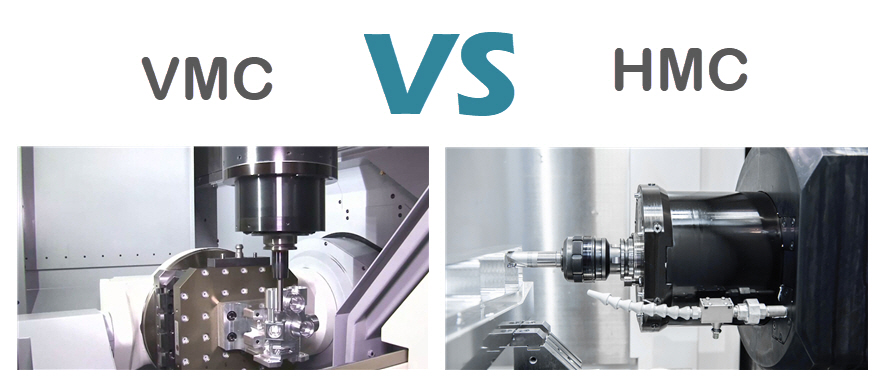

The difference between a vertical machining center and a horizontal machining center, many friends who are new to machining centers may be more confused. Today we will discuss the differences between VMC and HMC and their advantages and disadvantages. I hope this article will be helpful for those who are struggling to choose a vertical machining center or a horizontal machining center.

What is VMC and HMC?

VMC refers to the vertical machining center with the spindle axis perpendicular to the worktable. It can complete the processes of milling, boring, drilling, tapping and cutting threads. The VMC is at least three-axis and two-linkage, generally three-axis and three-linkage can be realized, and some can be controlled by five or six-axis.

HMC refers to the horizontal machining center with a horizontal spindle. It usually has an automatic indexing rotary table. It generally has 3 to 5 motion coordinates. The common one is three linear motion coordinates plus one rotary motion coordinate.

What Are the Differences Between CNC VMC and HMC?

1. Structure Difference Between VMC and HMC

The main difference between the VMC and HMC is the Z-axis structure. The Z-axis of the VMC moves vertically downward to complete the processing, while the Z-axis of the HMC moves horizontally downward to complete the processing, which is the main difference between them.

2. Workbench Difference Between HMC and VMC

The worktable of the VMC is usually a T-slot worktable with a cross slide structure. There are two sets of motion mechanisms responsible for the vertical movement of each other. The X-feeding worktable is covered on the Y-feeding guide rail. The worktable of the HMC is only designed to move in the X or Y direction. The worktable is generally a rotary worktable with a dot matrix screw hole table, and it is relatively easy to choose an interchangeable double worktable.

3. Different Parts Processed by CNC VMC and HMC Machine

The vertical machining center is suitable for processing disk, sleeve, and plate parts. It generally has three linear motion coordinate axes, and a rotary table that rotates along the horizontal axis can be installed on the worktable to process spiral parts.

The horizontal machining center can process parts with more than two sides or process holes and surfaces arranged radially around, such as box and shell parts; if the position accuracy of the processed parts is high, you should select high-precision horizontal machining center.

4. Advantages and Disadvantages of VMC and HMC

1) HMC

– Advantages: compared with VMC, the HMC is easier to remove chips during the processing of the workpiece, and it is more advantageous for the processing of complex recesses and the mold cavity. Due to the structural advantages of the horizontal machining center, the HMC can process large workpieces. Workpieces that are difficult or impossible to be processed by vertical machining centers can be processed on horizontal machining centers.

– Disadvantages: the HMC covers a large area, its structure is complex, and the price is more expensive than that of the VMC. It is inconvenient to debug the program of the horizontal machining center. It is not suitable to observe the tool movement path during processing. The workpiece is inconvenient for loading and unloading.

It can be seen from the advantages of the HMC that the horizontal machining center is more suitable for processing box-like workpieces, and can process the peripheral surface of the box-like workpieces. However, there are many inconveniences in the program debugging, tool trajectory observation, workpiece loading and unloading, workpiece measurement, so we have to reasonably look at the shortcomings and advantages of the horizontal machining center.

2) VMC

– Advantages: it occupies a small area with simple structure and relatively low price. It is more convenient to set up and adjust the program, and it has a wide range of applications.

– Disadvantages: it cannot process parts that are of large height. Chips cannot be easily removed when machining a cavity or a concave profile. In severe cases, it may damage the tool, destroy the processed surface, and affect the smooth processing. It is more suitable for processing workpieces with relatively small dimensions in the height direction.

When selecting HMC or VMC, you need to consider factors such as the processing object, processing technology, processing scope and equipment price. Now the machining center is developing in the direction of compounding. Before selecting a machining center type, factors such as production efficiency, processing technology requirements and equipment funds must be considered comprehensively, and the rationality of the selection plan must be measured by cost performance and applicability. If you want to know more information about the differences between CNC HMC and VMC or VMC machine controller panel, you can leave a message to contact our engineers.