Application Case Collection of HNC CNC Controller on 5-Axis Linkage CNC Machine Tool

As the top CNC controller manufacturer and supplier in China, HuazhongCNC 8 series CNC controller systems have been widely used in different countries such as China, Russia, U.A.E, Africa, Europe and etc. in a wide variety of industries such as mold, automobile as well as CNC machine retrofit. In this post, we will bring you a collection of HNC-8 series CNC controller application cases in supporting 5-axis linkage machining centers.

Case 1: HNC CNC Controller Used on Five-Axis Turning and Milling Center, Five-Axis Machining Center

In the cooperation between Baoji Machine Tool Group and Huazhong CNC, the BMC-500TV five-axis turning-milling compound and FV170 five-axis machining center of Baoji Machine Tool Group are equipped with HuazhongCNC HNC-848 closed loop CNC controller system in batches.

– Main Technical Features of Baoji Machine Tools

1. Five-axis linkage, milling and turning compound processing;

2. Five-axis fully closed loop, 20000 rpm milling lathe electric spindle, high-precision, high-speed machining;

3. Ram structure, roller guide rail, direct drive BC double rotary table;

4. 32-station chain tool magazine;

5. The linear axis positioning accuracy of the whole machine is 0.005mm;

6. Repeat positioning accuracy is 0.003mm.

– Key Technologies of HNC-8 Series CNC Controller Used

1. Turning and milling compound processing control technology

2. Spindle C/S switching control technology; power head C/S switching control technology

3. High-precision encoder, grating ruler, circular grating access technology

4. Collection and application of open data interface technology for big data of machine tool operating status

5. Automatic curve smoothing, five-axis RTCP function.

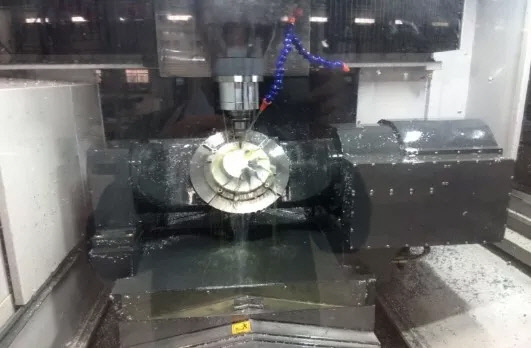

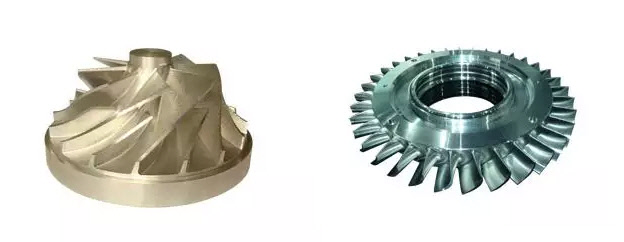

The BMC-500TV five-axis machining center is mainly used for complex and high-precision curved surfaces, polyhedral molds, impellers and other precision milling and turning complex processing.

Case 2: HNC CNC Controller Used on Five-Axis Machining Center

J-TECH CNC Technology Co., Ltd and HuazhongCNC have maintained a long-term and close cooperation relationship for many years. Hundreds of J-TECH 5-axis machining centers such as GL8 series are equipped with our HNC-8 series 5 axis CNC controllers.

– Main Technical Features of J-TECH CNC Machines

1. The spindle speed is 15000RPM, and the rapid traverse speed is 48m/min

2. The positioning accuracy is 0.005mm, and the repeat positioning accuracy is 0.003mm

3. Using six-axis five-linkage processing technology, adopting a gantry-type overall layout and a modular structure, it has different characteristics such as strong overall rigidity and good thermal stability

4. Optimize the combination of structures and key components such as the five-axis head to realize the high-speed and high-precision of the five-axis CNC machine tool.

– Key Technologies of HNC-8 Series CNC Controller Used in This Case

1. Five-axis RTCP high-speed and high-precision algorithm control

2. Intelligent functions such as optimization of process parameters, health protection, and broken tool detection based on processing big data.

The machine tool is mainly used for processing complex and high-precision curved surfaces, polyhedral molds, impellers, etc. As our customer reported, the JT-GL8 series 5-axis machining centers which are equipped with our HNC CNC controllers have good machining results and stable performance on site.

Case 3: HNC CNC Controller Used on Five-Axis Linkage Machining Center

Jier Machine Tool Group Co., Ltd and HuazhongCNC has established a long business relationship with each other for years. Its XHV27/XHV25/XHSV25 series of five-axis linkage machining centers and more models are equipped with our HNC CNC controller panels.

– Main Technical Features of Jier CNC Machining Centers

1. Equipped with a self-developed high-speed dual-angle CNC universal milling head

2. The maximum spindle speed is 24000r/min

3. The X, Y, and Z axes all adopt a grating ruler to achieve full closed-loop control

4. The B and C axes adopt high-precision angle encoders to achieve full closed-loop position feedback.

– Key Technologies of HNC-8 Series CNC Controller Used in This Case

1. High-speed and high-precision algorithm control

2. Five-axis linkage control technology (such as five-axis RTCP, five-axis normal forward and retreat, five-axis directional machining, five-axis great circle interpolation, etc.)

3. Double drive feed control

4. Spatial geometric error compensation (perpendicularity, straightness, winding compensation and other functions)

5. Intelligent functions such as optimization of process parameters, health protection, and broken tool detection based on processing big data

6. Internet access.

Jier Machine Tool’s XHSV series five-axis linkage machining center has been successfully applied in XX Aircraft Industry (Group) Co., Ltd., Beijing XX Machine Manufacturing Company, Tianjin XX Rocket Manufacturing Co., Ltd. and other enterprises. It is mainly used for high-speed and high-efficiency machining of large aluminum alloy and composite material structural parts and other industries, and semi-finishing and finishing of large-scale automobile molds.

Case 4: HNC CNC Controller Used on Five-axis Machining Center & Five-axis Gantry Milling Machine

Shandong Weida Heavy Industries Co., Ltd. and HuazhongCNC have cooperated for many years. Our HNC-8 series CNC controller has been installed in batches on Weida VMC1000/VMC850 five-axis machining centers and GMC1120 five-axis gantry milling machines.

– Main Technical Features of Weida Machine Tools

1. X, Y, Z three-axis 45mm ultra-wide line rail to ensure the rigidity of machine tool processing;

2. High-speed, high-precision spindle, the maximum speed is 8000rpm;

3. The cooling system uses a large flow, high-lift water pump to ensure sufficient cooling under high-speed cutting;

4. The whole machine adopts a closed protective cover and a fully enclosed electric cabinet, which is safe and beautiful.

– Main Technologies of HNC CNC Controller Used in This Case

1. Five-axis RTCP

2. The curve is automatically smoothed

3. On-line inspection of workpieces.

At present, the customer’s VMC1000/VMC850 five-axis machining center has been used for machining complex parts such as turbines, blades, and spatial cams, with stable performance and high machining accuracy.

Case 5: HNC CNC Controller Used on 5-Axis Machining Center

The Fujian WN5V-320Z-AC five-axis machining centers of Weinuo CNC Co., Ltd. are equipped with HuazhongCNC 8 series CNC system.

– Main Technical Features of Weinuo Machining Centers

1. The spindle speed is 10000rpm

2. There are two models of AC swing head and BC swing head, A axis (B axis) range -15°~+115°, C axis 360° rotation movement

3. Positioning by four conical positioning pins, hydraulic clamping, and the speed increased by 2-3 times compared with traditional driving technology

4. It is used to process products with different shapes and profiles, including conical, concave-convex, flat special profile and various complex space curved products.

– Key Technologies of HNC-8 Series CNC Controller Used in This Case

1. High-speed, high-precision motion control technology

2. NCUC fieldbus

3. Third-party electric spindle servo drive matching technology

4. High-precision encoder, grating ruler, and circular grating access technology

5. Linkage control technology (RTCP, normal advance and retreat, directional machining, great circle interpolation, etc.)

6. Automatic calibration of machine tool structure error

7. Linkage dynamic error detection

8. Collection and application of big data of machine tool operation status, open data interface technology.

Weinuo WN5V-320Z-AC five-axis machining center is mainly used to process parts with complex curved surfaces such as impellers and blades, as well as various molds such as cavity molds, die-casting molds, and stamping molds.

If you are seeking reliable CNC machine or CNC controller manufacturer, this will be the right place for you as we provides a wide range of 2-5 axis CNC products such as CNC milling machine, CNC milling center, CNC lathe, machining center and etc.