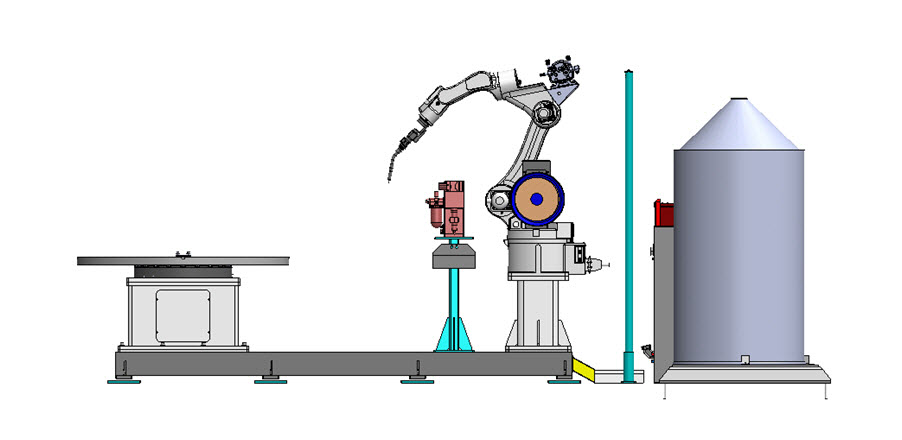

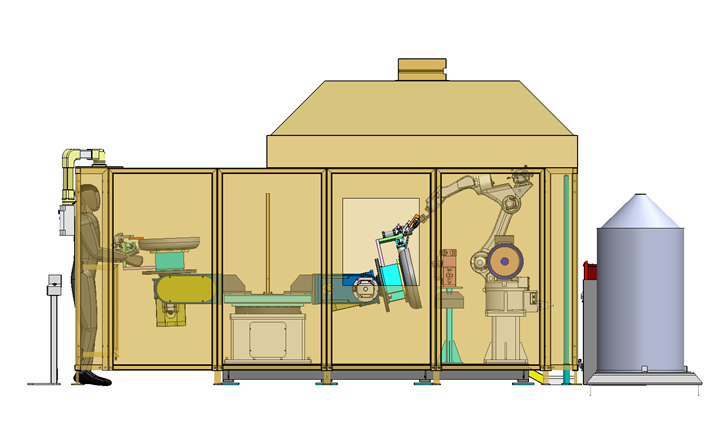

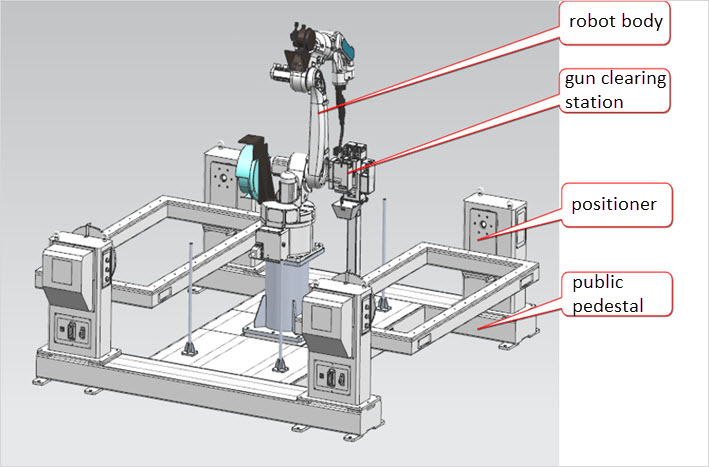

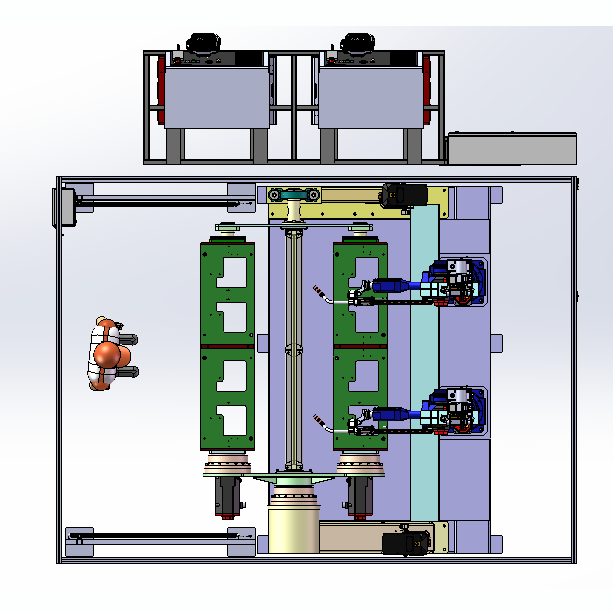

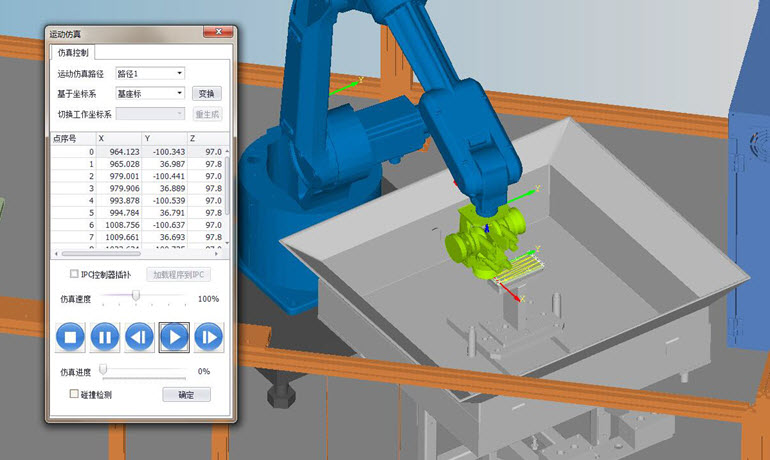

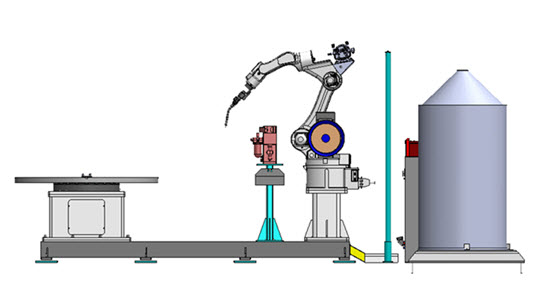

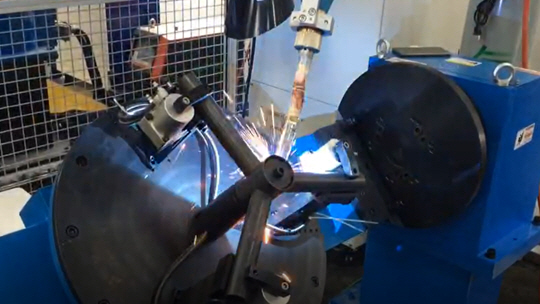

Offline Programming Simulation

During the design process of the automatic welding scheme and the subsequent implementation of the scheme, HNC-RJH series welding robot arm is equipped with offline programming simulation software for customers, thereby improving the reliability of the robotic welding cell or robotic welding system scheme, and ensuring the stability of the project construction and operation.