| Specification |

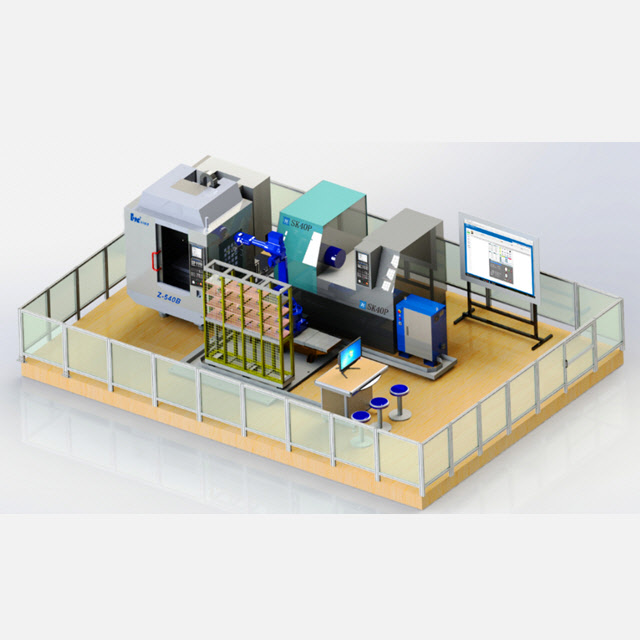

| 1. Robot body |

1.1 |

Six degree of freedom, tandem articulated industrial robot |

/ |

| 1.2 |

Repeatability |

±0.02mm |

| 1.3 |

Load capacity |

⩾3kg |

| 1.4 |

Horizontal reachable distance |

⩾571.5mm |

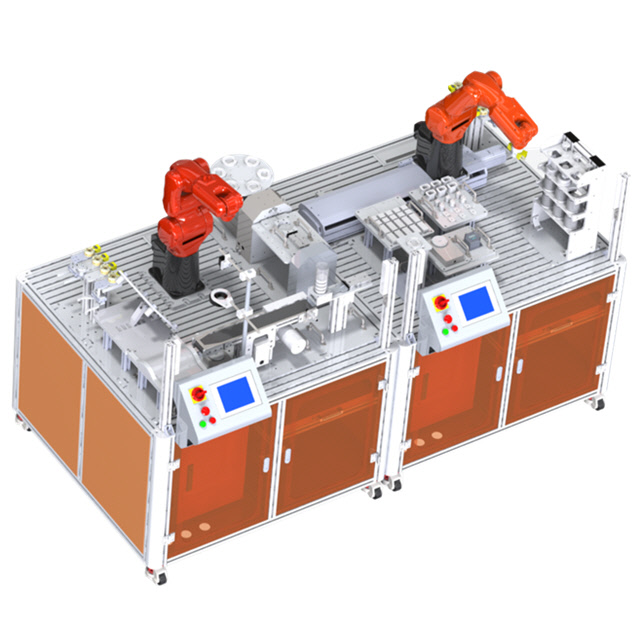

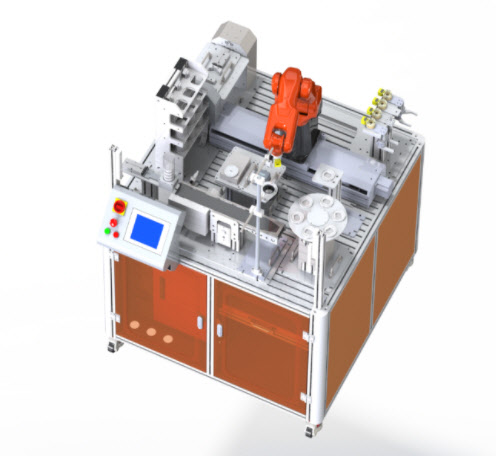

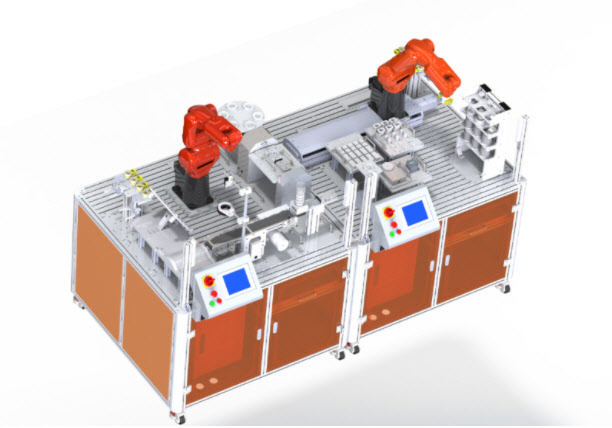

| 2. Standard training platform |

2.1 |

Size |

⩾1280 × 1280 × 880 mm |

| 2.2 |

Module fixing plate |

⩾12 |

| 2.3 |

Maximum electrical interface capacity |

⩾3 groups |

| 3. Quick change tool module |

3.1 |

1 set of fixed bottom plate |

/ |

| 3.2 |

1 set of quick-change bracket |

| 3.3 |

1 set of quick-change plate |

| 3.4 |

4 sets of tools and stainless steel handles |

| 4. Sample set

|

4.1 |

Assembly kit (base model, motor model, reducer model, flange model) |

The motor model is divided into three parts: motor housing, rotor and end cover |

| 4.2 |

Can be fully assembled or customized

assembly. |

/ |

| 4.3 |

Palletizing kit

Requirements: square and rectangular can be mixed |

Type of parts: ⩾2 types (square and rectangular) |

| 5. Drawing module |

5.1 |

Adapt to standard training platform positioning installation |

/ |

| 5.2 |

Number of drawings |

⩾10 |

| 5.3 |

Preset pattern |

Straight line, arc, curve |

| 5.4 |

Plane drawing board size |

290×223×2mm |

| Surface drawing module |

/ |

| 5.4.1. Adapt to standard training platform positioning installation |

| 5.4.2. Number of drawings |

⩾10 |

| 5.4.3. Preset pattern |

Straight line, arc, curve |

| 5.5 |

Surface drawing size |

250×200×35mm |

| 6. Handling module |

6.1 |

Number of parts that can be accommodated |

18 |

| 6.2 |

Arrangement form |

3 rows, 6 columns |

| 6.3 |

The workpiece to be handled is triangular, and the handling slot has a digital identification. |

/ |

| 7. Palletizing module |

7.1 |

Palletizing position |

⩾2 positions |

| 7.2 |

Pallet size |

65×65×25mm |

| 7.3 |

The robot has a palletizing technology package, which can quickly perform palletizing programming. |

/ |

| 8. General Electric Interface Kit |

8.1 |

Bus module |

Support Ethercat or DeviceNet |

| 8.2 |

Digital expansion module |

1)Digital channel: 32DI/DO

2)Voltage: DC24V |

| 9. Peripheral Controller Kit |

9.1 |

Controller |

Memory capacity for users: ⩾100K/4MB. |

| Digital channel: ⩾14DI/10DO |

| Analog channel: ⩾2AI/AO |

| AI(0-10v) AO(0-20mA) |

| 9.2 |

HMI |

Display: ⩾7 inches TFT display, 16777216 colors |

| Resolution: ⩾800×480 pixels |

| 10. Assembly module |

10.1 |

Contains double shaft cylinder |

/ |

| 10.2 |

V-block fixed clamping range is variable |

| 10.3 |

Installation method: installed above the rotary positioner module controlled by the servo motor |

| 11. # type feeding module |

11.1 |

Plexiglas tube length |

⩾150mm |

| 11.2 |

Use cylinder mode to control the discharge of materials |

/ |

| 12. Conveyor transport module |

12.1 |

Conveyor included |

| 12.2 |

Effective working width |

⩾60mm |

| 12.3 |

Max. speed |

⩾4m/min |

| 12.4 |

Support 0-20mA analog speed control |

/ |

| 13. RFID module |

13.1 |

Contains reader’s support part |

| 13.2 |

Communication Interface |

RS422 |

| 13.3 |

Reader |

Operating frequency/ rated value: 13.56MHz |

| 14. Visual inspection module |

14.1 |

Visual inspection system |

1/1.8″ CMOS imager: color, 6 million pixels |

| Imaging mode: ⩾640×480 |

| Resolution: 3072×2048 |

| Frame rate: 17fps |

| 14.2 |

Weighing unit |

Weighing area: ≤φ68mm |

| Weighing range: 0-1000g |

| 15. Storage module |

15.1 |

Storage capacity |

⩾6 |

| 15.2 |

Compatible workpiece types |

⩾4 types |

| 15.3 |

Ethernet I/O acquisition module |

Data acquisition channel: ⩾6DI |

| 16. Rotary feeding module |

16.1 |

Speed |

⩾20º/s |

| 16.2 |

Load |

⩾5kg |

| 16.3 |

Drive |

Stepper motor +

harmonic reducer |

| 17. Positioner module |

17.1 |

Travel range |

±45° |

| 17.2 |

Speed range |

10~30°/s |

| 17.3 |

Drive method |

AC servo + worm gear reducer |

| 18. Typical process application module kit |

18.1 |

Including welding, grinding, gluing, various types of process for workpieces ⩾2 |

/ |

| 19. Motor assembly module |

19.1 |

Material pallet size (length * width) |

300×250mm |

| 20. Checkerboard module |

20.1 |

Board size |

300×300×8mm |

| 20.2 |

Chess piece array |

5×5 |

| 20.3 |

Can accommodate chess pieces size |

φ55mm |

| 21. Material temporary storage module |

21.1 |

Placement height |

Vertical distance from desktop 150mm |

| 21.2 |

Can accommodate positioning workpiece types |

⩾2 |

| 22. Offline programming software |

22.1 |

Genuine software, exclusive license, free upgrade |

/ |

| 22.2 |

The offline programming software and the training platform industrial robot body are the same brand. |

| 22.3 |

It can realize offline programming of more than 3 brands and more than 3 models of industrial robots of each brand; |

| 23. Secondary development software package |

23.1 |

Support the secondary development for the industrial robot system |

| 23.2 |

Support SDK for secondary development programming of industrial robot system |

| 23.3 |

Support the customization of the teach pendant interface |

| 23.4 |

Provide controller configuration software |

1) Can realize the communication connection with the robot controller;

2) Provide basic teaching of the robot, including jog, inching, reset alarm functions, etc. |

| 24. Oil-free silent air pump |

24.1 |

Using pure copper motor to provide air supply for the innovation platform |

Equipment power: 600W

Displacement: 45L/min

Capacity: 30L |

| 25. Computer, desk and chairs |

|

|

/ |

| 26. Process monitoring module |

|

Used for video recording during training and assessment, to monitor the operation of equipment. |

| 26.1 |

Camera hardware configuration |

1) The highest resolution is up to 1920×1080 @25fps

2) Support PoE power supply function |

| 26.2 |

U-shaped camera bracket |

Made of high-quality steel pipe, the bottom can be perfectly docked with the platform, and network communication cables can be installed inside |