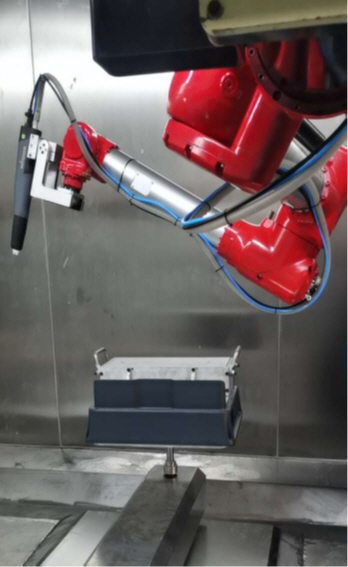

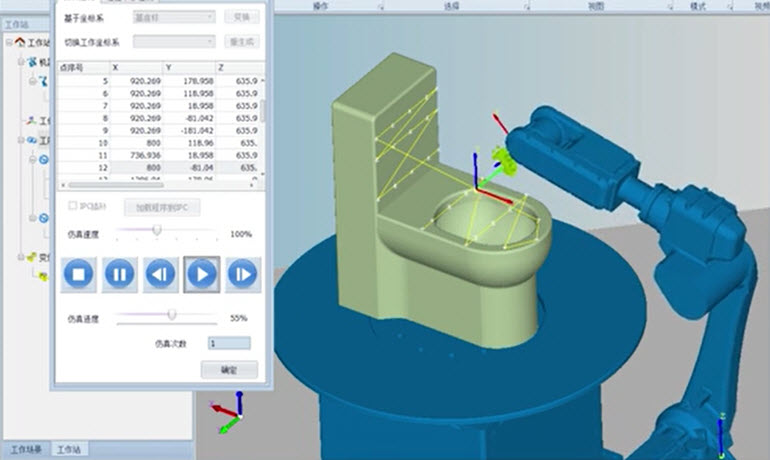

In the process of preliminary spraying scheme design & subsequent scheme implementation, HNC-RBR spray painting robot arm can be equipped with offline programming simulation software for customers to use for offline programming, which can help customers save on-site debugging time, and can also increase the reliability of the robotic painting system and improve the stability of subsequent spraying scheme execution.

Spray Painting Robot Arm

Get A Free Quote

Products List

RBR616

RBR616 Plastic Injection Molding Machine Robot

- Axis: 6-axis

- Working radius: 1599.6mm

- Payload: 16kg

RBR625

RBR625 Car Painting Robot for Automotive Industry

- Axis: 6 axes

- Working radius: 1849.5mm

- Payload: 25kg

Application & Configuration

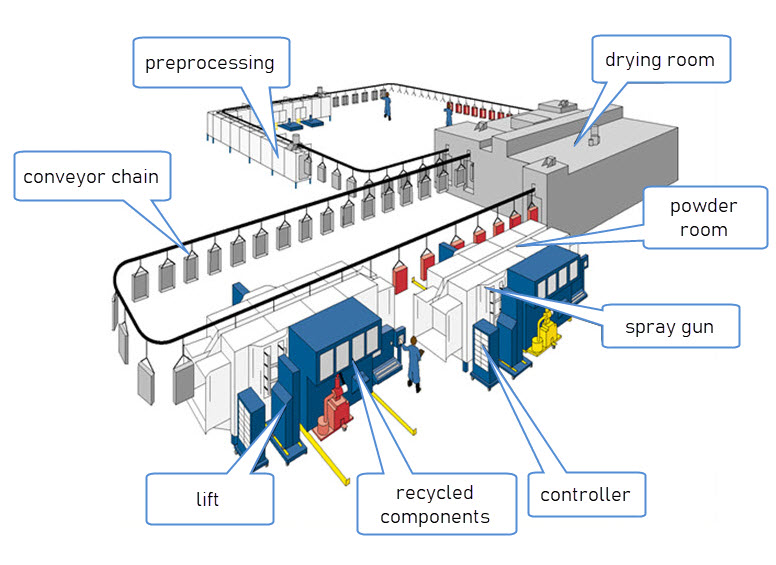

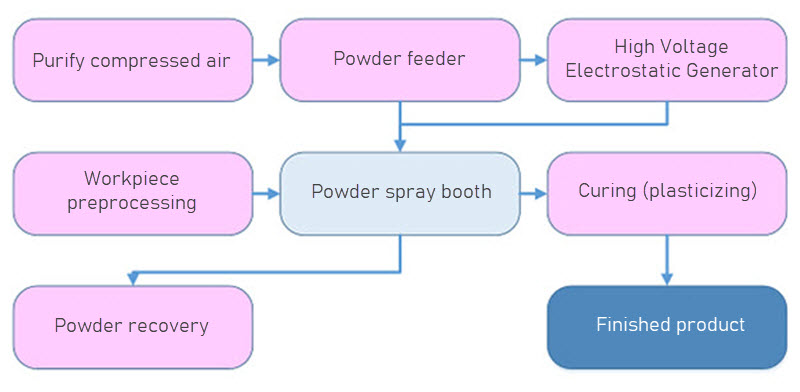

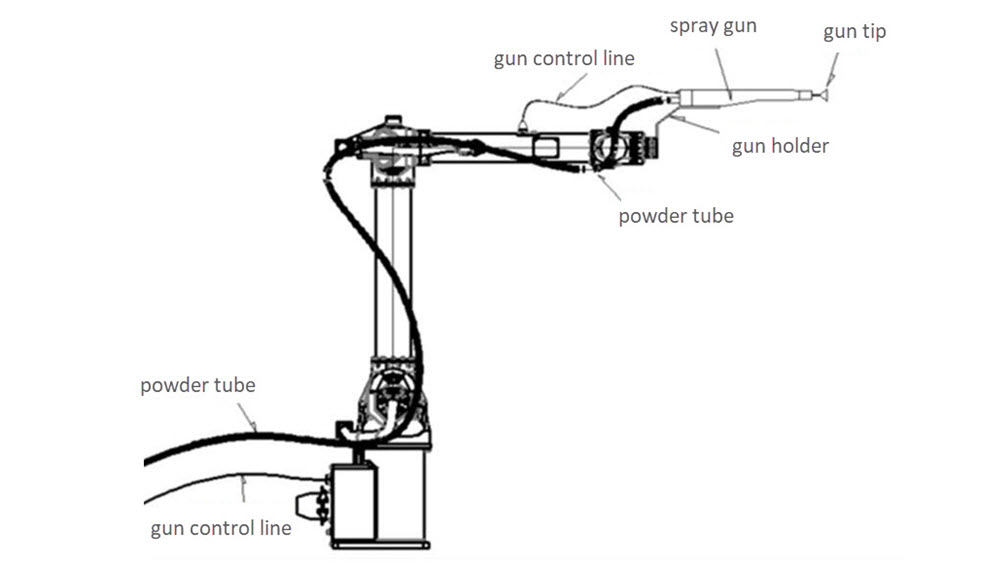

HNC-RBR series spray painting robot arm, combined with customer automation needs and customer production scenarios, can integrate with spray guns, tooling, generators and pneumatic systems of different uses and specifications to realize more overall solutions for robot automatic spraying. Our robotic painting robot arms have a large active radius with high flexibility, which can realize painting on the inner surface and outer surface with accurate spraying trajectory, improve the spraying quality and material utilization rate.

General Configurations

According to the actual automatic spraying or painting needs of customers, we can provide a robotic spray painting system with the following conventional configurations:

| Item | Model | Details |

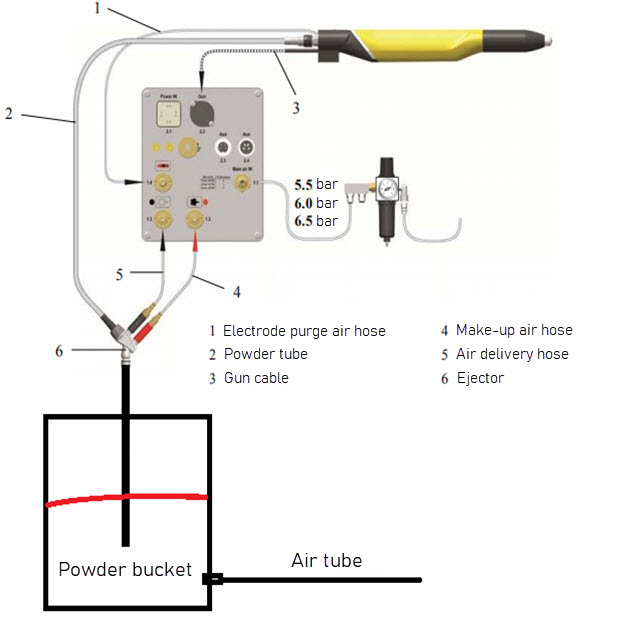

| Spray painting robot arm | HSR-BR610/ HSR-BR616/ HSR-BR625/HSR-BR5110 | Including teaching pendant, electric control cabinet, English system, built-in spraying process package |

| Spray gun | Standard√ | Integrated at the end of the robot |

| Powder supply tube | Standard√ | Integrated into the robot body |

| Electrostatic generator | Standard√ | / |

| Ejector | Standard√ | / |

| Electrical accessories | Standard√ | Including encoders, cables, components, etc. |

Get A Free Quote