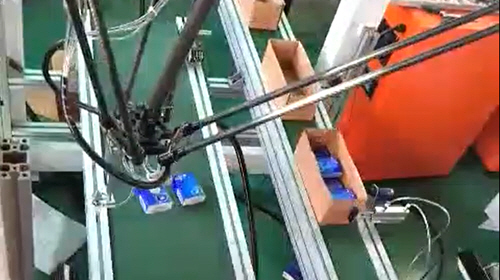

In the preliminary design stage and subsequent plan implementation, HNC-RDT series high-speed pick and place robotic arms are also equipped with offline programming simulation software for customers to use. After capturing the target object through teaching programming or vision system, the picking robot kit realizes the transportation and processing of the target object, and provides a reliable and stable pick-and-place automation solution.

Pick and Place Robotic Arm

Get A Free Quote

Products List

RDT401

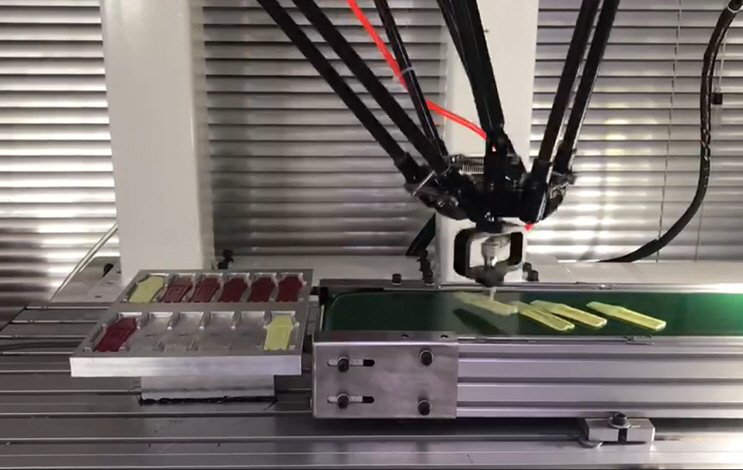

RDT401 Delta Robot Pick and Place System

- Axis: 4 axes

- Working radius: 135Z/200R(mm)

- Payload: 1kg

Application & Configuration

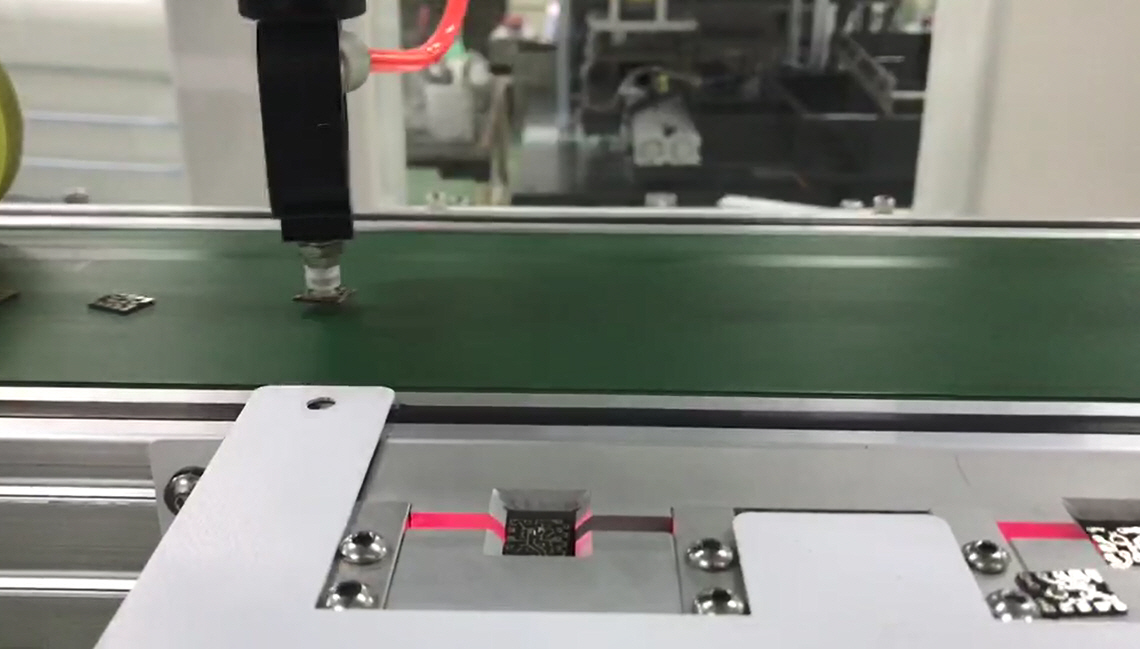

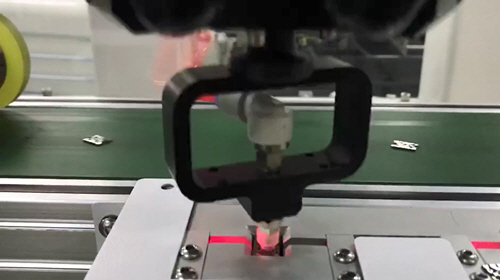

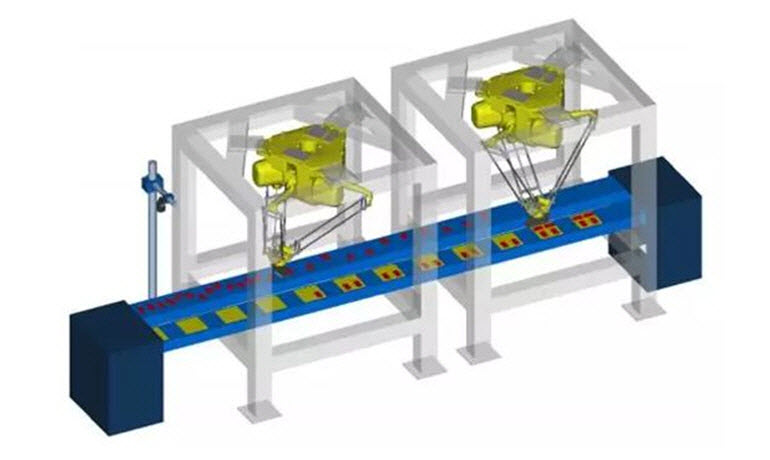

Combined with actual application scenarios and production process requirements, HNC-RDT series pick & place robot arm, cooperating with DT_Catch Software and integrating vision settings, tool settings, trajectory settings, palletizing modules and calibration modules, provides streamlined and convenient automatic pick and place solutions for customers. Many automated picking and placing solutions have been formed in the processing and assembly fields of food, medicine, electronics and warehouse.

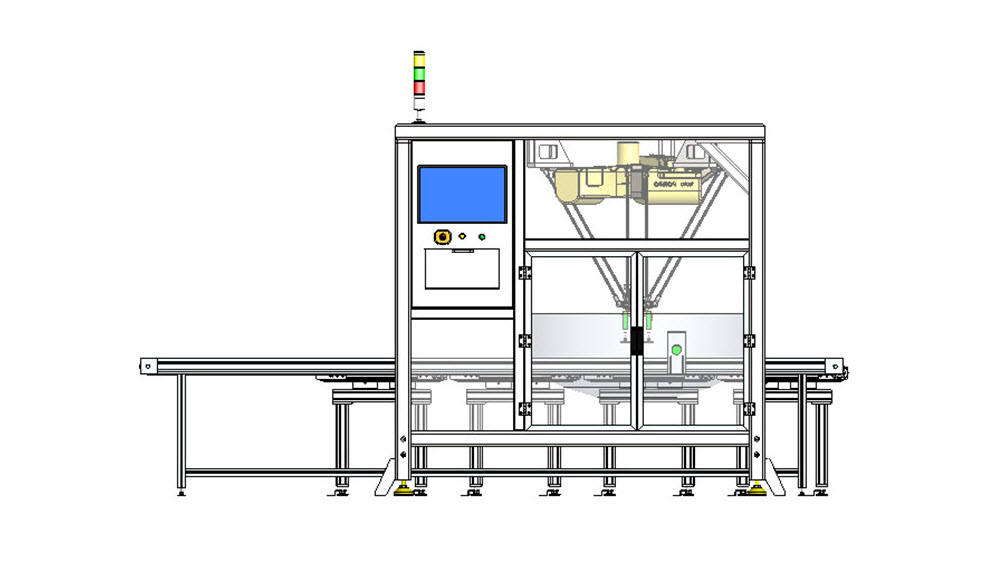

General Configurations

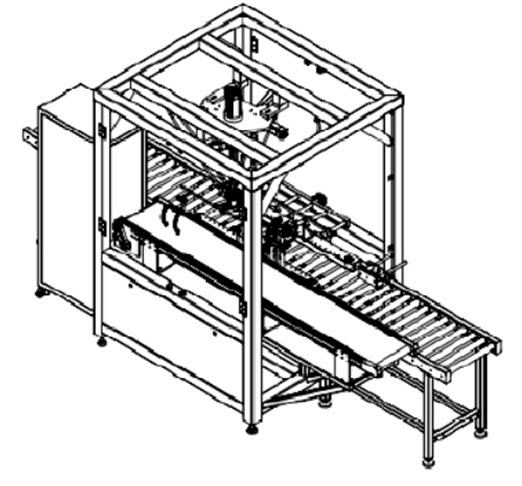

According to the actual production process needs of customers, we provide customers with the following routine configuration of robotic pick & place automated system:

| Item | Model | Details |

| Delta Robot | HNC-RDT401

HNC-RDT803 HNC-RDT1208 |

Including teach pendant, electric control cabinet, English system |

| Robot Gripper | Standard√ | Integrated at the end of the robot |

| Visual System | Standard√ | Including industrial computer, camera, lens, light source, visual software, display screen, keyboard and mouse |

| Frame | Customized | Fixed robot, optional |

| Transmission lines | Customized | Conveying material, optional |

Get A Free Quote