Based on the RBR series, the brand-new generation of HNC-RBR610 assembly line robot that was designed for glass grinding, flat grinding, engraving, and milling and other machines now has upgraded the protection level of its leading arm (tooling arm). This upgrade now allows the leading arm to be sprayed or even immerse in water with IP 67 waterproof rating. Ultimately, it works faster, loads heavier, and the protection gets better.

RBR610 Assembly Line Robot Features

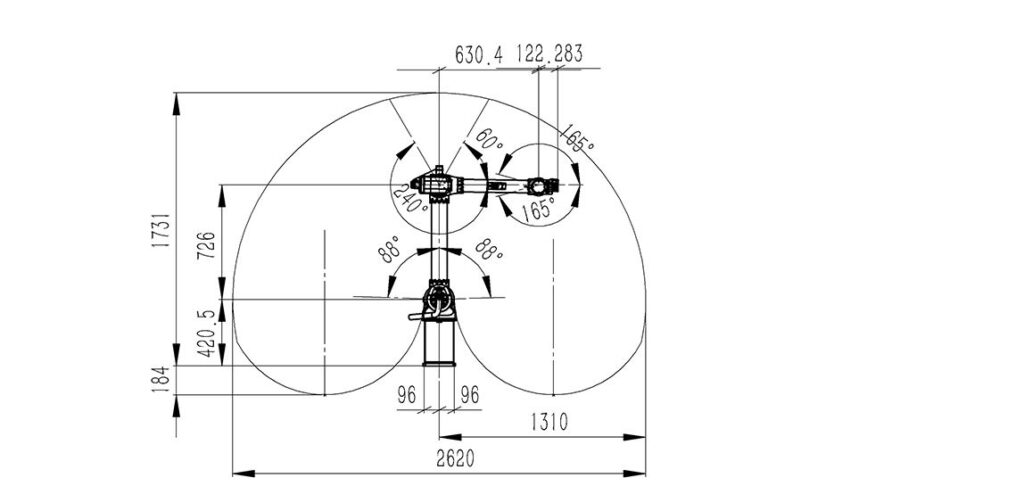

1. Small installation occupation: the base of RBR610 is very small. It only occupies less than 0.06㎡, which allows it to work in a very small space. It can support the loading and unloading of various machine tools.

2. High precision: the average repeat positioning accuracy is a minimum of 0.03 mm, and the maximum is 0.05 mm.

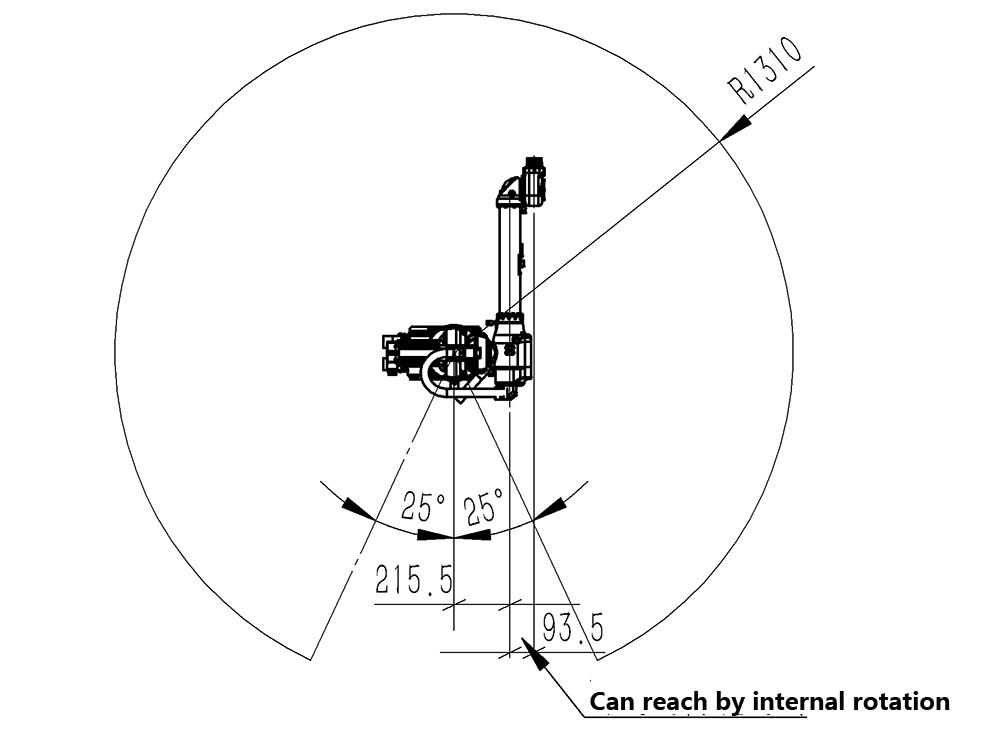

3. High flexibility: the RBR610 robot can run to the rear part of the robot through the internal rotation mode, and the combined motion range of the J1 axis can reach 620° (part of the angle is reached by internal rotation). The circle layout is unlimited.

4. Longer arm and stronger load capacity. The lightweight design, high-speed motor, and high-precision reducer are used to increase the robot arm length to 1310 mm and the maximum load of 10 kg.

5. Faster: with an innovative structure and high-speed motor, the robot has the smallest inertia from the inside. The standard handling time for internal rotation with a pitch of 1800 mm can be controlled within 3s, which is more than 20% faster than a general six-axis robot.