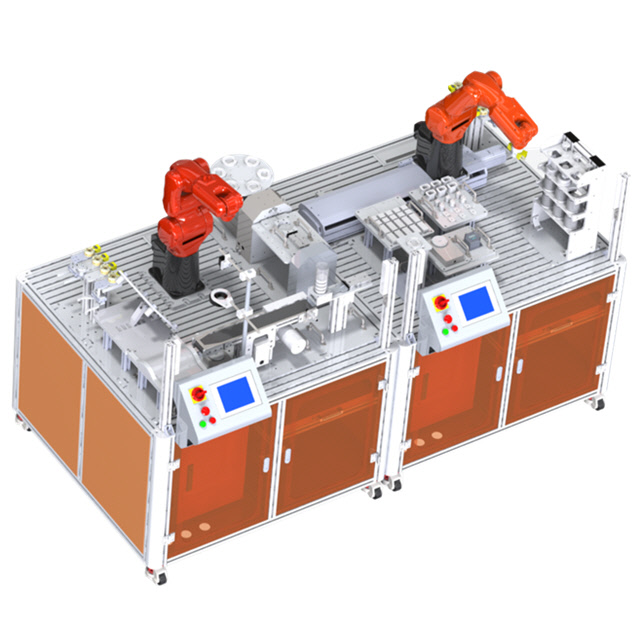

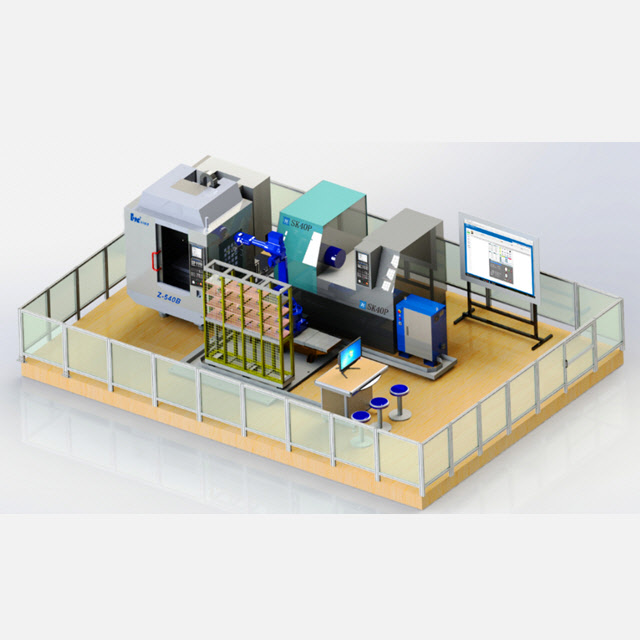

This combined with the comprehensive application of digital design technology, intelligent control technology, high-efficiency processing technology, industrial Internet of things, RFID digital information technology and other “software” to form the intelligent manufacturing training platform integrated theory and practice. This platform has functions such as digital design of parts and process planning, real-time manufacturing data collection during processing, virtual automation of processing, traceability of processing status based on RFID and flexibility of processing. The training platform includes CNC lathe system, machining center system, digital stock bin, central control system, MES system management software and electronic billboard, etc.

Intelligent Manufacturing Simulation Training Platform

Main Features

- Intelligent manufacturing simulation training platform takes the concept of “equipment automation + lean manufacturing + IT application in management + Efficient manual”.

- Integrates CNC processing equipment, industrial robots, data information collection and control equipment, programming simulation and other typical processing and manufacturing equipment into the intelligent manufacturing unit as the “hardware” system.

Description

01Parameters

02Hardware list of intelligent manufacturing training platform:

| No. | Name | Quantity | Unit | Note |

| 1 | CNC lathe machine | 1 | set | Configurable with virtual axis to run actual machining program |

| 2 | CNC system for machining center | 1 | set | Configurable with virtual axis to run actual machining program |

| 3 | Industrial robot controller | 1 | set | / |

| 4 | Robot teach pendant + control system | 1 | set | / |

| 5 | Five-color light | 1 | set | Real-time display of material status’ information for each bin |

| 6 | Visualization system and display terminal | 1 | set | Display the operating status of the machine tool, workpiece processing status, processing effect, processing log, data statistics, etc. |

| 7 | Central Electric Control System | 1 | set | Responsible for peripheral equipment and robot control, to achieve the master control of the process and logic of the intelligent manufacturing unit |

| 8 | RFID reader and RFID chip | 1 | set | Reading and writing of workpiece processing status, processing information, etc. |

| 9 | Computer for programming and design | 2 | set | Refer to specific technical parameters |

Software list of intelligent manufacturing training platform:

| Name of software | Hardware | Basic function |

| MES | Industrial computer + touch screen | Order management function, machine tool monitoring, processing program management, etc. |

| (Manufacturing Execution System) | ||

| PLC for master control | Intelligent production line for master control system (industrial computer + touch screen) | Responsible for peripheral equipment and robot control, to achieve the master control of the process and logic of the intelligent manufacturing unit |

| Intelligent manufacturing simulation software | 1 set of computer for programming and design | Unit equipment simulation, virtual installation and commissioning, layout optimization |

| CAD/CAM | 1 set of computer for programming and design | Optional |

| Intelligent Manufacturing Teaching Resource Package | industrial computer + touch screen | Learning and evaluation of knowledge points related to intelligent manufacturing |

Patent Certification, Excellent Strength

In the history of more than 30 years of development, it has won many awards and more than 1,000 patent certifications.