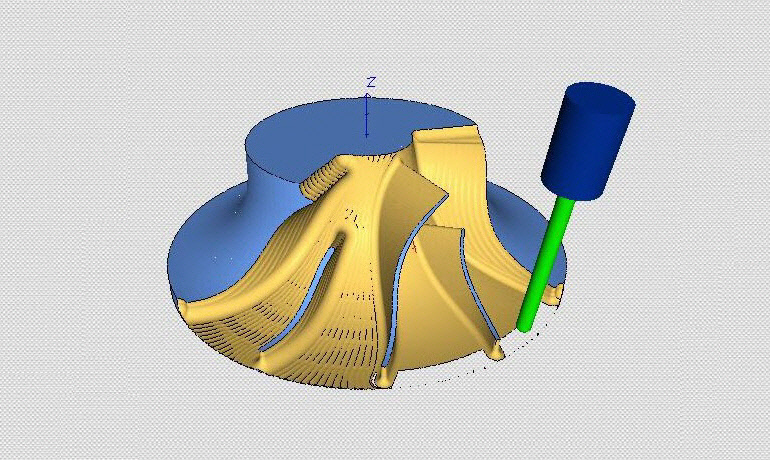

The CNC mill machine controllers support quick preview of the tool path, have multi-axis machining big data analysis software, and support 3D simulation which can perform graphic simulation of NC program before processing and also perform graphical simulation during processing in real time.

CNC Milling Controller

Get A Free Quote

Products List

HNC-808Di-M

HNC-808Di-M CNC Milling & VMC Machine Controller Panel

- Axis: 3 axis

- Protocol: M3, NCUC, Ethercat

- Screen: 10.4 inches

HNC-808XP-M

HNC-808XP-M Online CNC Motion Controller System for Milling

- Axis: 3 axes

- Protocol: Ethercat, NCUC, M3

- Screen: 9 inches

HNC-818Di-M

HNC-818Di-M CNC Controller for Machining Center

- Axis: 4-5 axis

- Protocol: NCUC, Ethercat

- Screen: 12 inches

HNC-848Di

HNC-848Di Closed Loop 5 Axis CNC Controller Kit

- Axis: 5-32 axes

- Protocol: NCUC, Ethercat

- Screen: 17 inches

Features & Functions

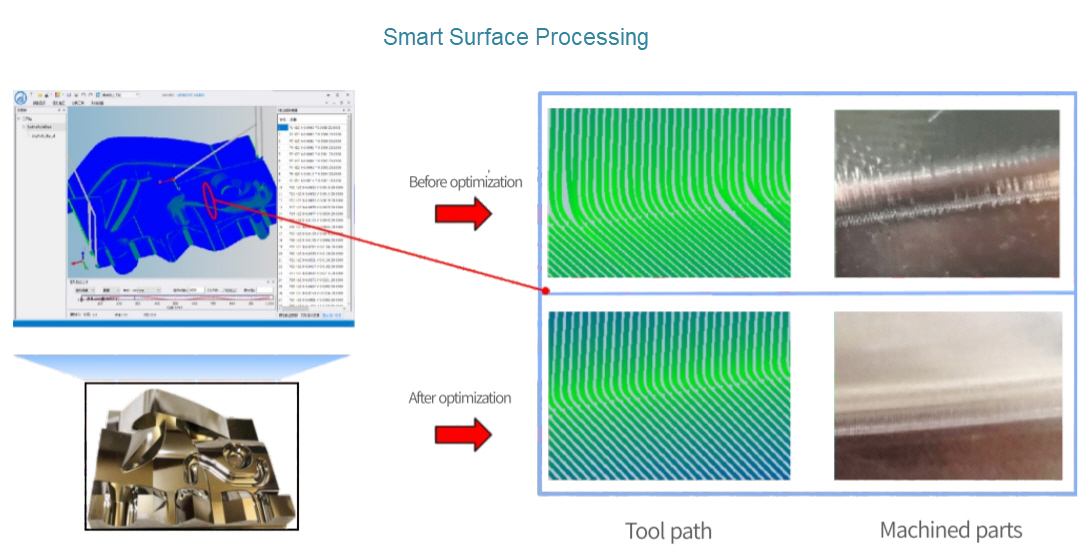

The CNC milling machine controller panel uses unique high-speed and high-precision control technology to help users improve processing quality and processing efficiency, and provide users with optimized machining solutions for producing high-precision molds, auto parts, hardware, 3C products and etc.

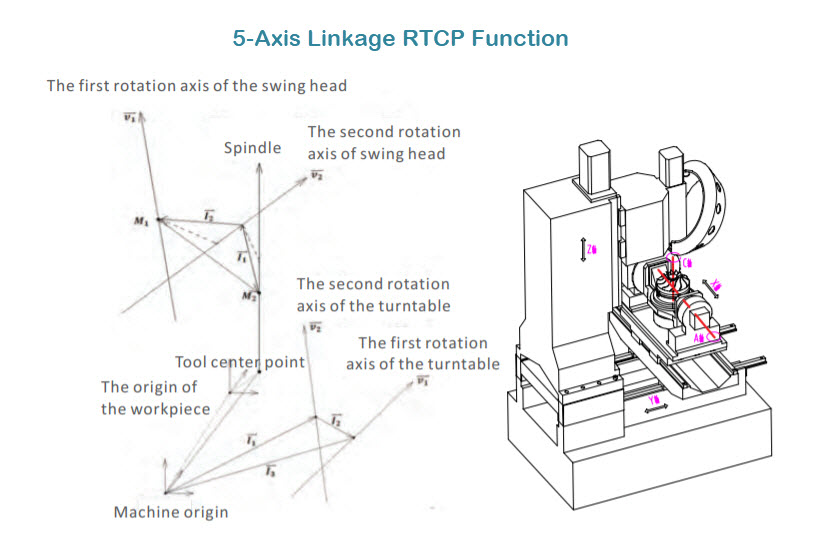

The CNC milling controllers support a wide variety of milling machines, machining centers and turning-milling machines which are of 3, 4, 5, 6 and more axes. You can choose suitable models according to the practical needs for high-efficiency and high-precision machining to various simple and complex parts such as curves, curved surfaces, grooves, gears, bevels, etc.

Our CNC mill controllers are designed with rich and powerful functions such as multi-axis and multi-channel, tapping synchronization error compensation, smart surface processing, five-axis RTCP function, tool measurement, iNC-Cloud service and etc.