HuazhongCNC Won the Second Prize of the 2020 National Science and Technology Progress Award

The National Science and Technology Award is the highest award in the field of science and technology in China. It is divided into five awards: the National Highest Science and Technology Award, the National Natural Science Award, the National Technological Invention Award, the National Science and Technology Progress Award and the People’s Republic of China International Science and Technology Cooperation Award.

On November 3, the 2020 National Science and Technology Awards Conference was held in the Great Hall of the People. A total of 264 projects, 10 scientific and technological experts and 1 international organization were selected by the conference.

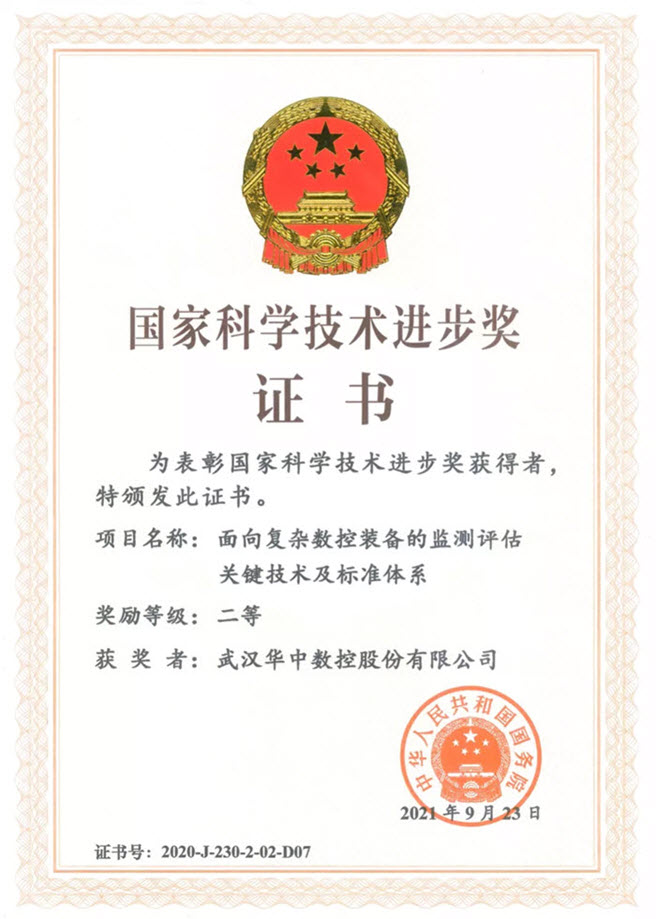

The two projects – “Key technologies and standard systems for monitoring and evaluation of complex CNC equipment” and “S-shaped specimen detection method and machining accuracy improvement technology for five-axis CNC machine tools” which are jointly completed by HuazhongCNC and other units, won the 2020 National Science and Technology Progress Second Prize.

The Key Technology and Standard System of Monitoring and Evaluation for Complex Numerical Control Equipment

Led by Beijing University of Aeronautics and Astronautics and jointly completed by HuazhongCNC and other units, the project of “Key Technologies and Standard System for Monitoring and Evaluation of Complex CNC Equipment” won the second prize of the 2020 National Science and Technology Progress Award.

S-shaped Specimen Detection Method and Machining Accuracy Improvement Technology for Five-axis CNC Machine Tools

The precision detection and performance evaluation of five-axis linkage high-end CNC machine tools are recognized worldwide problems.

With the support of the National Science and Technology Special Project “High-end CNC Machine Tool and Basic Manufacturing Equipment” which is led by Chengdu Aircraft Industry (Group) Co., Ltd., the “S-shaped specimen” five-axis machine tool testing method is independently developed by HuazhongCNC and other units. It can test the geometric accuracy, positioning accuracy, comprehensive processing efficiency, comprehensive surface processing and a series of problems such as vibration, flutter and etc., can find and search for the causes of failures that affect the machining accuracy of machine tools, and can also solve the problem of machine tool accuracy loss or repair after reduction. It has become an international standard for testing the working accuracy of five-axis machining machine tools, and has achieved a “zero” breakthrough in the international standard field of high-end CNC machine tools.

HuazhongCNC CNC controllers

The award is an affirmation of HuazhongCNC’s independent innovation and R&D strength in the field of numerical control systems, as well as the application of technical results. It fully reflects HuazhongCNC’s core competitiveness in the field of numerical control systems, enhances HuazhongCNC’s brand promotion, and promotes the application of CNC system in various fields.