Stamping Robotic Arm

Get A Free Quote

Products List

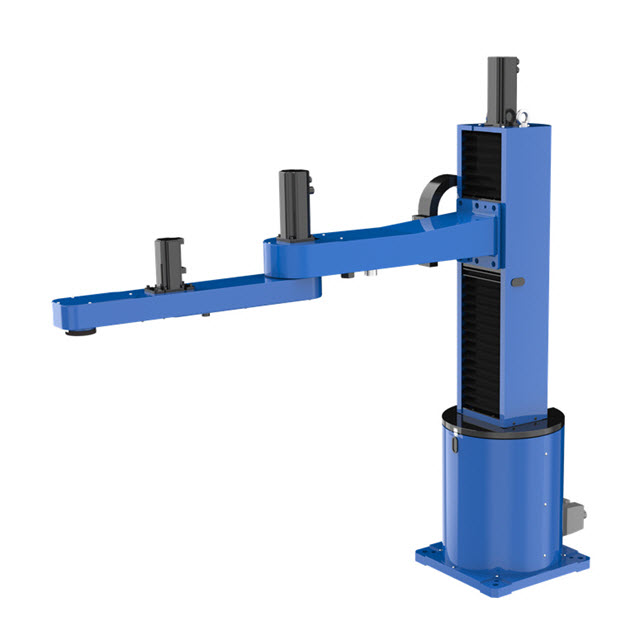

RHC403

RHC403 Lightweight Small Industrial Robot Arm

- Axis: 4 axes

- Working radius: 585mm

- Payload: 3kg

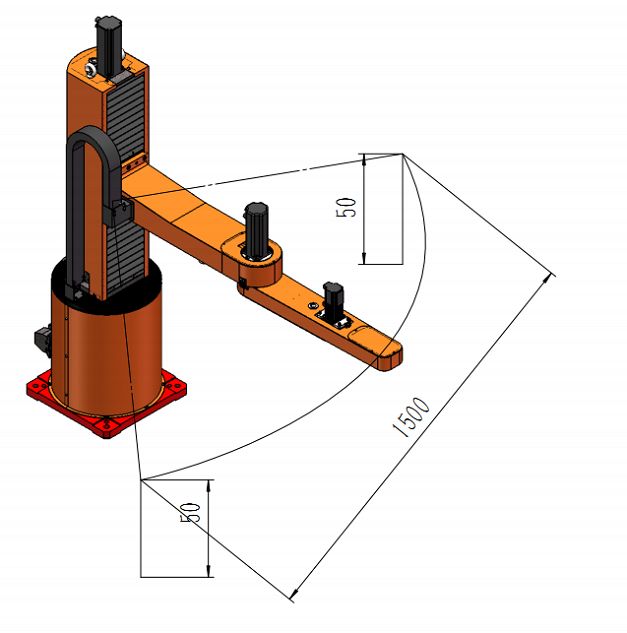

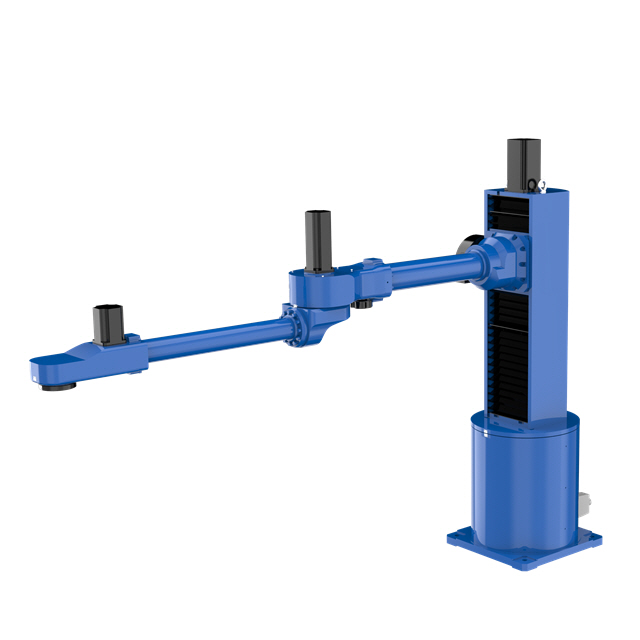

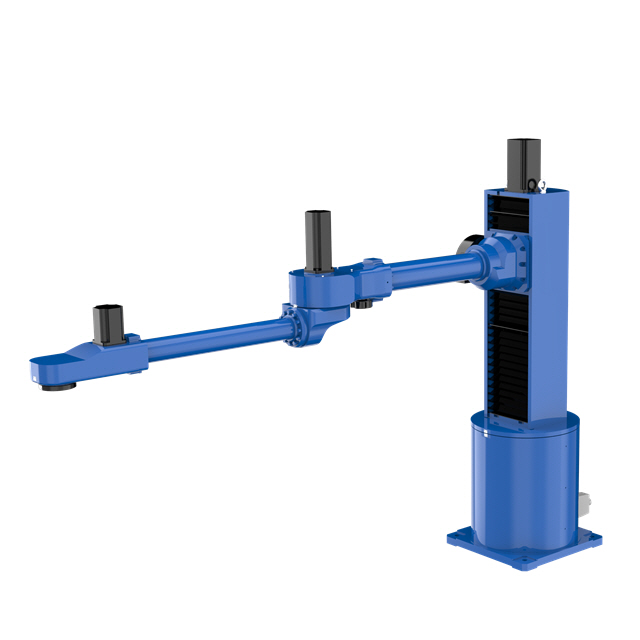

RHC420

RHC420 Long Reach Robotic Arm for Punching Press

- Axis: 4 axes

- Working radius: 2000mm

- Payload: 20kg

Application & Configuration

Stamping robotic arms are a type of robotic arm used in stamping applications to replace manual operation with an intelligent device. They are equipped with man-machine interfaces and PLC control systems that make it easy to set feeding speed and step distance, stamp target output, and display current stamping quantity. Robotic material handling systems have evolved to include stamping applications, with advances in intuitive user interfaces, 3D vision systems, sensing capabilities, and automatic tool changing. End effectors are used as the robot’s hand to contact the part being transferred. Robotic arms are specialized for speed and equipped with accurate sensors that act as precise guides. They are used in material handling, machine tending, and press tending applications, with the tooling fitted to the end of the robotic arm being of great importance in press tending operations.

General Configurations

According to the current customer needs, the general configurations of robotic welding cells or systems we provided to customers are as follows:

| HC Robot types | HSR-HC403 | HSR-HC410A | HSR-HC415 | HSR-HC420 |

| Numbers of axis | 4 | 4 | 4 | 4 |

| Rated load | 3 kg | 10 kg | 15 kg | 20 kg |

| Max. Working radius. | 585 mm | 1402 mm | 1402 mm | 2000 mm |

| Repeated positioning accuracy | ±0.02 mm | ±0.05 mm | ±0.05 mm | ±0.08 mm |

Product Features

1. High-cost performance

It is a general-purpose industrial robot with low cost, can be reprogrammed for handling and assembly, and the cost can be recovered for one year.

2. Long life

Adopting a high-precision high-rigidity harmonic reducer, the service life can be as long as several decades. Once invested, benefited for many years

3. High speed

The operating speed is twice that of the 6-joint robot of the same level

4. High precision

Using a high-precision RV reducer, the repeatability at the end reaches ±0.05MM

5. High integration

The built-in signal line and the trachea are plug-and-play, no cumbersome wiring is required, and the internal cable does not slide, which can maintain a failure-free rate for a long time.

6. High rigidity

The key structural parts are made of high-strength cast iron and cast aluminum, ensuring high rigidity of the robot under high-speed operation

7. High smoothness

Advanced control systems and servo drive systems are used to achieve high-speed and smooth motion performance, with almost zero time pause at the transition point.

8. High load

The maximum payload of the wrist is 10/20kg, which can achieve large coverage of the workpiece and can easily respond to new business orders from customers

Get A Free Quote