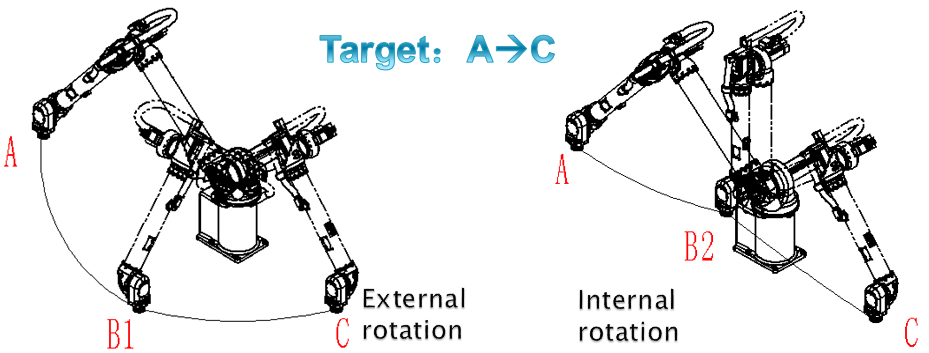

1. Unique bi-rotation structure makes the injection moulding robot move directly to the target point with shorter distance, bring more efficiency for you.

2. High protection level of IP67 makes the injection molding robot adapt to hard working conditions such as spraying with water.

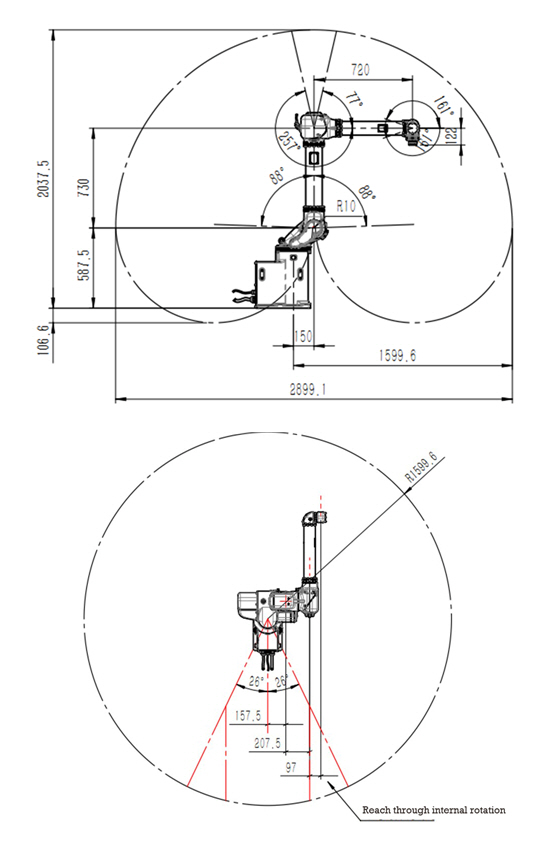

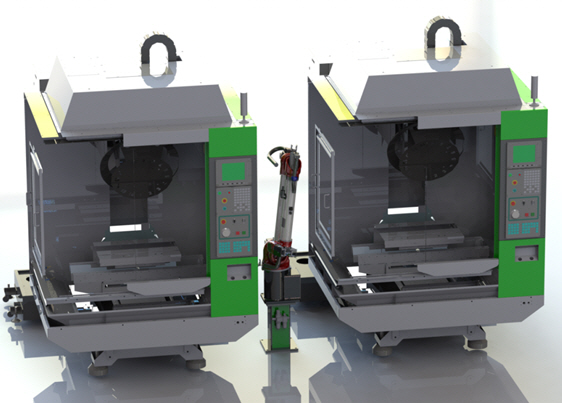

3. Small installation occupation of less than 0.1㎡, which can perfectly load and unload pieces for machine tools or injection molding machines in narrow space.

4. Light weight of 128kg, much lighter than other 6 axes robot with the same payload and arm length, which can be installed in any directions, adapt to different workshop conditions.

5. Using high-speed motor and high-precision reducer of international famous brands, ensuring the reliability and long cycle life of the robot.

Comparison with other 6 axes robot:

|

Name |

RBR robot series |

Other 6 axes robot series |

|

Structure |

With its bi-rotation structure, the forearm of RBR robot can rotate through internal rotation, which can minimizes the moving distance to the target point. |

The ordinary 6 axes robot has no internal rotation function, when rotates from the inside to a point in the back of the robot, it has to rotate 360°, which is slow and heavy. |

|

Precision |

For RBR series robots with the same level of arm length, the repeatability is ±0.06mm, and the average repeatability is ±0.03mm |

Repeatability ±0.1mm |

|

Speed |

Using high-speed servo motors coupled with a small internal rotational motion inertia, RBR series is easy to achieve high-speed operation. The maximum speed of joints is 600°/s, TCP maximum linear speed is 2m/s |

The maximum speed of other ordinary 6 axes robot joints is 180°/s, and the maximum speed of TCP is 1m/s. |

|

Motion mode |

Have both the external rotation function and internal rotation function, which is HNC unique original design and has got the patent in the United States. |

Only have the external rotation function |