| Item |

Training Content |

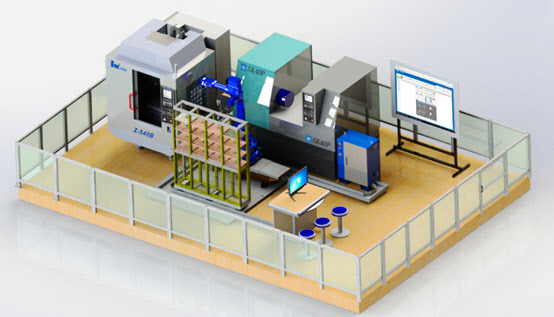

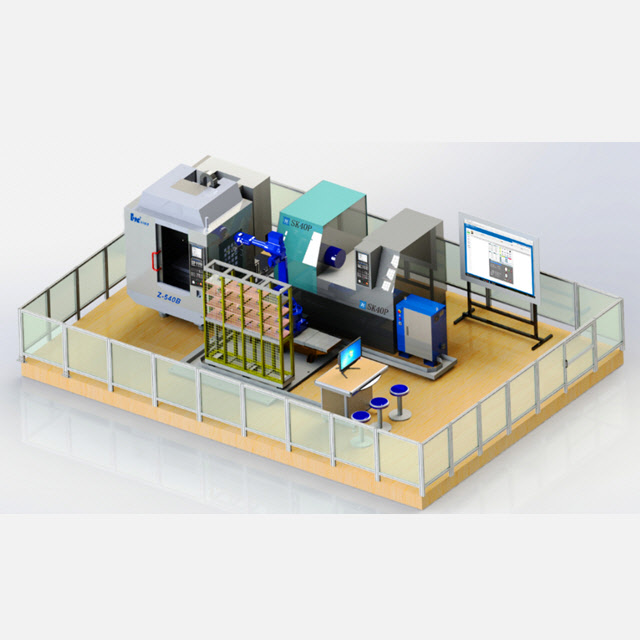

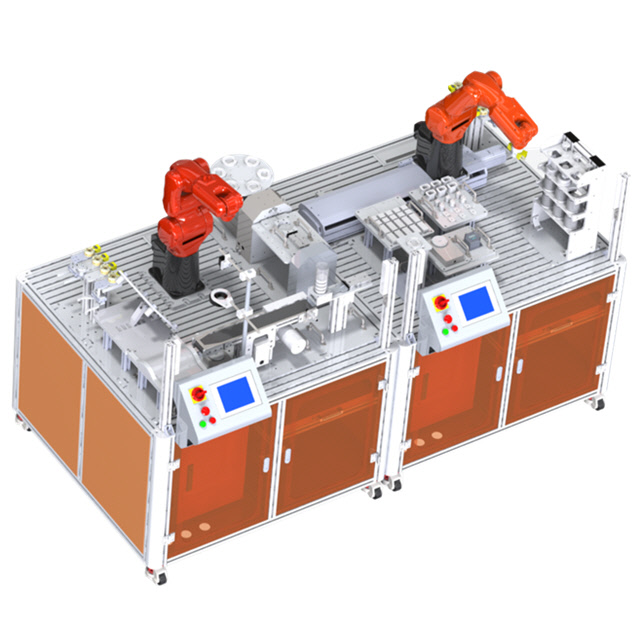

| Digital three-dimensional stock bin |

. Learn the basic principles of digital three-dimensional stock bin |

| · Realize joint debugging between material and robot |

| · Fault diagnosis and treatment of digital three-dimensional stock bin |

| Six-joint robot |

· Robot teaching and programming operation |

| · Robot offline programming simulation |

| · Robot fault diagnosis processing |

| · Joint debugging of robots and other equipment |

| Robot fixture |

· Learn how the robot fixture works |

| · Learn how to install and debug robot fixtures |

| · Understand the practical application of robot fixtures in industrial sites |

| The seventh axis of robot |

· Learn how the seventh axis of the robot works |

| · Learn how to install and debug the seventh axis of the robot |

| · Understand the practical application of the seventh axis of the robot in the industrial field |

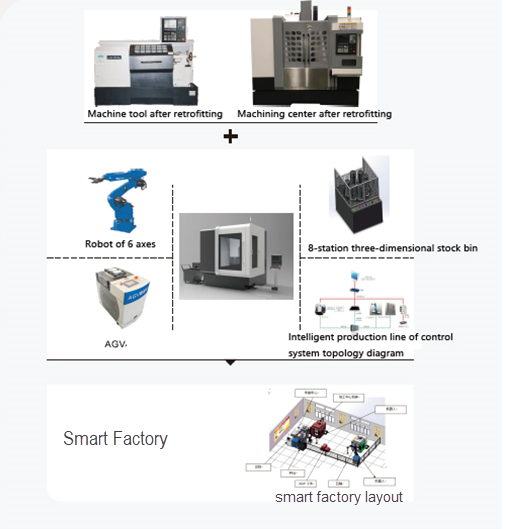

| Machining center |

· Learn how the machining center works |

| · Learn how to debug machining center program |

| · Learn how to operate and maintain machining centers |

| ·Understand the practical application of machining centers in industrial sites |

| CNC lathe machine |

· Learn the working theory of CNC lathe |

| · Learn how to debug CNC lathe programs |

| · Learn how to operate and maintain CNC lathes |

| · Understand the practical application of CNC lathes in industrial sites |

| Online inspection system |

· Learn the composition and working theory of the detection system |

| · Learn how to install and debug the detection system |

| · Understand the actual application of the detection system in the industrial field |

| Safety protection system |

· Learn the basic theory of safety protection systems |

| · Signal interconnection processing with robots, machine tools and other equipment |

| Master control system for intelligent production line |

· Understand the basic theory of intelligent production line control system |

| · Communication and data collection of CNC, Robot, RFID, PLC, testing equipment, etc. |

| · Network management of CNC equipment |

| · PLC, Robot, CNC programming and operation |

| · Remote fault diagnosis and analysis |

| · RFID communication connection, data reading and writing |

| · Production task dispatch of production line |

| · Workpiece size measurement and tool wear compensation in machine tool |

| · Intelligent equipment scheduling and control, master control PLC programming and debugging |

| RFID management system |

· Learn the working theory of RFID electronic label system |

| · Learn how to install and debug the RFID electronic label system |

| · Understand the practical application of RFID electronic label system in industrial field |

| Master control PLC for production line |

· Understand the basic functional modules of the master control PLC for intelligent production line |

| · Learn and master the programming and operation of main control PLC modules |

| · Learn and master the methods of master control PLC fault diagnosis and troubleshooting, and carry out related treatments |

| Big data collection software |

· Understand the basic theory of real-time big data collection |

| · Learn and master the use of the big data acquisition software DCAgent, and set the parameters |