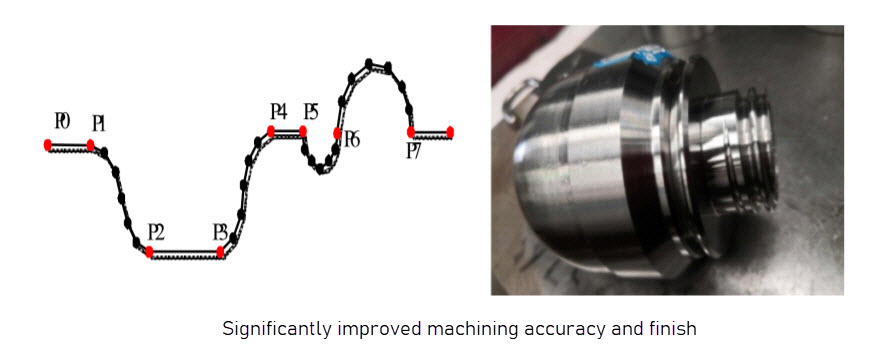

1. The high-performance drive adopts hardware current loop, wave trap, over modulation, field weakening and other technologies to significantly improve the response characteristics of the current loop and the stiffness and response of the servo control.

2. All series of low-voltage LMDD series and high-voltage HMDD series motors are equipped with 16 million lines of high-resolution photoelectric encoders as standard, which improves the processing accuracy and finish.

3. Based on the QT development framework, customized HMI development is more convenient and quicker. The interface styles such as menu, display style, and display color can be adjusted on the spot. The modular design is convenient and fast for secondary development and special machine development.

4. Support multi-station display, multi-spindle load display, multi-station graphic display, parameter classification displays, convenient modification and query, custom display configuration, custom classification.

5. Real-time monitoring of program running status, real-time display of register status, integrated oscilloscope function, user-friendly debugging.

6. The joint adjustment between the system and the servo is simple and intuitive, and the system guidance and recommended value methods increase the adjustment efficiency, covering all loops and tapping.

7. Simple PLC function switch: realize the selection of different functions and panel control of different device models through the PLC switch of the interface. Realize convenient debugging and matching in machine tool factory.

8. Simple compensation data import method: RENISHAW laser interferometer measurement data is input in native format, without modification and calculation, it is directly loaded into the system through U disk, the compensation takes effect immediately, and the machine tool accuracy detection efficiency is increased by 2 times.

9. Thread repair function: After processing a thread, re-clamping is performed, and the coordinates are recorded in the thread repair function interface, and the “recut thread effective” function button is turned on, and then secondary processing is performed, and the thread can be re-tooled.