The 4th Metalworking Technology Innovation Forum

Introduction of The 4th Metalworking Technology Innovation Forum

On June 28, 2023, The 4th Metalworking Technology Innovation Forum was successfully held in Wuhan, Hubei, China. This forum is sponsored by the Metal Processing Magazine of the Machinery Industry Information Research Institute and undertaken by Wuhan Huazhong Numerical Control Co., Ltd. with the theme of “digital intelligence innovation and high-end leadership”, This forum further explored the China future development trend of the metal processing industry. And it aims to solve the problem of promoting digital and intelligent technologies to accelerate the empowerment of the manufacturing industry and promote the broad application of digital and smart technologies.

This forum invited the leaders of the Machinery Industry Information Research Institute, experts in the metal processing industry, and representatives from the chief engineer/factory director/equipment procurement director/technical manager/technical backbone craftsman of metal processing enterprises from all over the country. They addressed the current industry demands and delivered speeches on topics such as industry development, processing difficulties, and intelligent applications.

Expert presentations

Zhou Baodong

Zhou Baodong, deputy secretary of the Party Committee of the Machinery Industry Information Research Institute, said that the machine media and metal processing magazines will continue to pay attention to industry trends, strive to provide more and higher-quality communication platforms and work together with everyone to contribute to my country’s metal industry.

Chen Jihong

Chen Jihong, chairman of Wuhan Huazhong Numerical Control Co., Ltd., emphasized that metal processing is inseparable from machine tool equipment. Huazhong CNC is willing to join hands with metal processing and all participating companies to deeply integrate and innovate collaboratively, to jointly explore the road of diversified green and innovative development of high-end equipment manufacturing, to create an ecological chain belonging to China’s manufacturing industry, and to take a step forward for my country’s manufacturing industry.

Zhou Ji

Zhou Ji, an academician of the Chinese Academy of Engineering, made a report on the theme of “Accelerating the Construction of a Manufacturing Power with Intelligent Manufacturing as the Main Attack”. He emphasized that it is now a critical period for the development of the core technology of a new round of industrial revolution in intelligent manufacturing, and China’s machine tool industry can fully concentrate on its advantages to achieve strategic key breakthroughs and key leaps and realize the overtaking and leapfrog development of China’s machine tool industry. Facing the country’s major strategic needs, with enterprises as the main body and the government as the leading force, it will gather and integrate the superior forces of the country’s industry, education, research, and government to achieve a strategic breakthrough in high-end CNC machine tools.

Jiang Tao

Jiang Tao, a Beijing researcher of user companies in key fields and deputy chief engineer of intelligent manufacturing, gave a report titled “Application of Domestic Equipment and CNC Systems in Key Fields”, pointing out that the new generation of high-end manufacturing equipment is developing towards ultra-high speed and high precision. Domestic high-end industrial master machines put forward higher demands. Through the extensive application of Huazhong CNC’s high-end CNC system, it is an innovative model of high-end manufacturing equipment for collaborative research and application demonstration.

Wan Qian

Wan Qian, vice president of Wuhan Huazhong Numerical Control Co., Ltd., published a report on the theme of “Research and Application of High-end CNC Systems in the Field of Intelligent Manufacturing”, focusing on the introduction of the Huazhong 8 CNC system with “better, faster and smarter” as the market orientation. Nearly 150,000 sets have been sold and applied. Huazhong CNC’s high-speed, high-precision, and intelligent technology and Internet + technology help machine tool companies and user companies to improve quality and efficiency.

Xiang Hua

Xiang Hua, vice president of Wuhan Huazhong Numerical Control Co., Ltd., gave a report titled “Application Achievements of Huazhong High-end CNC System”, introducing that Huazhong CNC adheres to the national demand-oriented approach and has achieved major breakthroughs in overcoming the core technology of high-end CNC systems. We comprehensively integrated five-axis machining technology and digital + network + intelligence, and comprehensive upgrade and iteration on key five-axis CNC technologies such as high-quality five-axis machining, CAM&CNC integration, on-machine measurement, and remote operation and maintenance.

Other experts

In addition, experts, scholars, and representatives from Harbin University of Science and Technology, Beijing Xinghang Electromechanical Equipment Co., Ltd., and many other universities and enterprises have shared technology and research reports on different topics in the field of metal processing.

On-site Q&A

At the end of the meeting, on-site Q&A and technical exchange sessions were set up. Expert representatives and enterprise technical representatives conducted further technical exchanges with colleagues in the industry. Starting from the actual processing needs, it covers the technical problems, processing difficulties, detection methods, etc. in the current production. The representatives also answered relevant questions very well, with frequent interactions and enthusiastic responses.

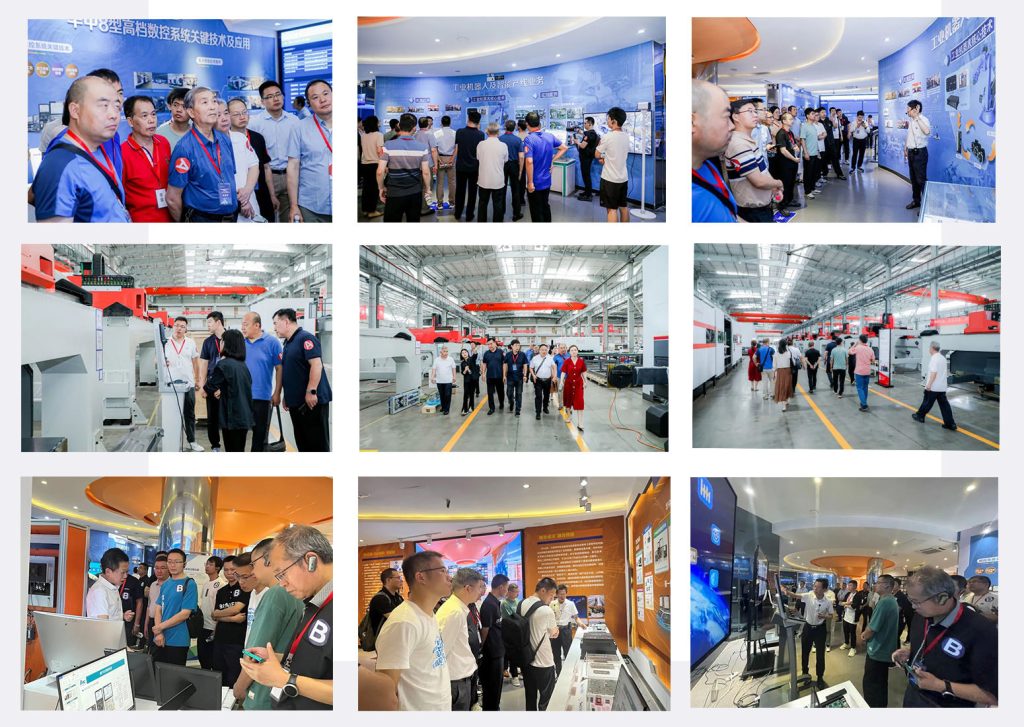

Expert visits Huazhongcnc

On the second day of the forum, more than 100 experts and scholars visited the two enterprises of Wuhan HuazhongCNC and Wuhan Huagong Laser. At Huagong Laser, they visited the five-axis linkage CNC system, which is the core unit technology of the three-dimensional five-axis laser cutting machine realized by the joint research of Huazhong CNC and Huagong Laser. The efficiency and performance of the system in the test are comparable to those of world-class brands. During the visit to Huazhong CNC, experts, and scholars learned about the development history of Huazhong CNC and the products and technical demonstrations of robots, electric vehicles, CNC systems such as Huazhong 8 high-performance CNC systems, iNC-Cloud CNC cloud housekeeper, and Huazhong 9 artificial intelligence CNC system. They all expressed their full affirmation and praise for the overall strength and related achievements of our company.