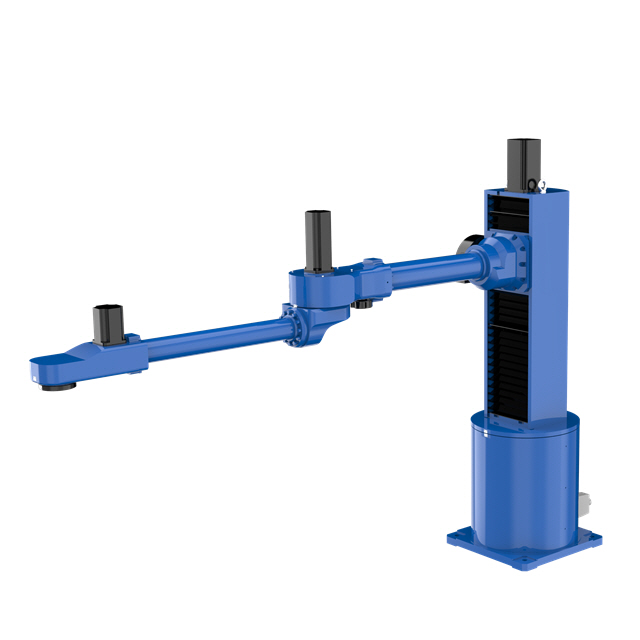

Our RHC415 4-axis robotic arm is widely used in different scenarios for workpieces loading and unloading for metal stamping machines or punching machines, and there are many successful application cases such as Haier washing machine stamping production line, electric oven stamping production line, Galanz microwave oven stamping production line, hardware stamping production lines and etc. Please watch the below video to see the successful application case of our RHC415 metal stamping robot.

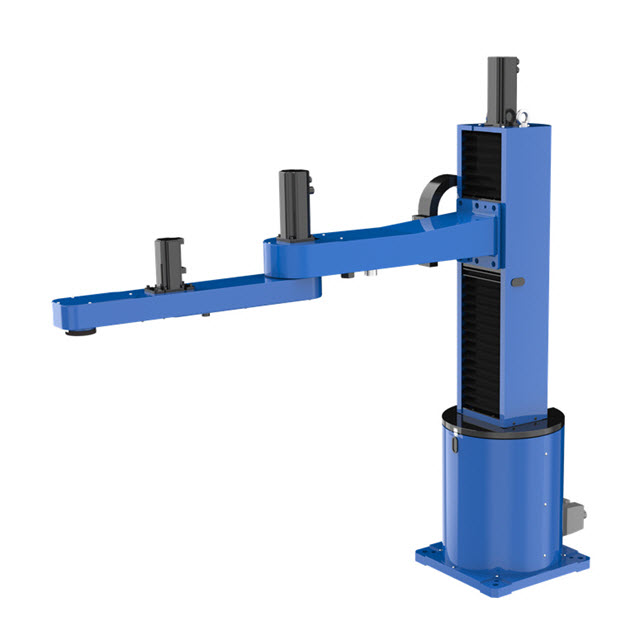

- Multi-functional: besides of loading and unloading pieces for metal stamping machines, it can also be reprogrammed for other applications such as handling and assembly.

- Long service life: adopt high-precision and high-stiffness imported reducer, the 4-dof robotic arm can be used for several decades.

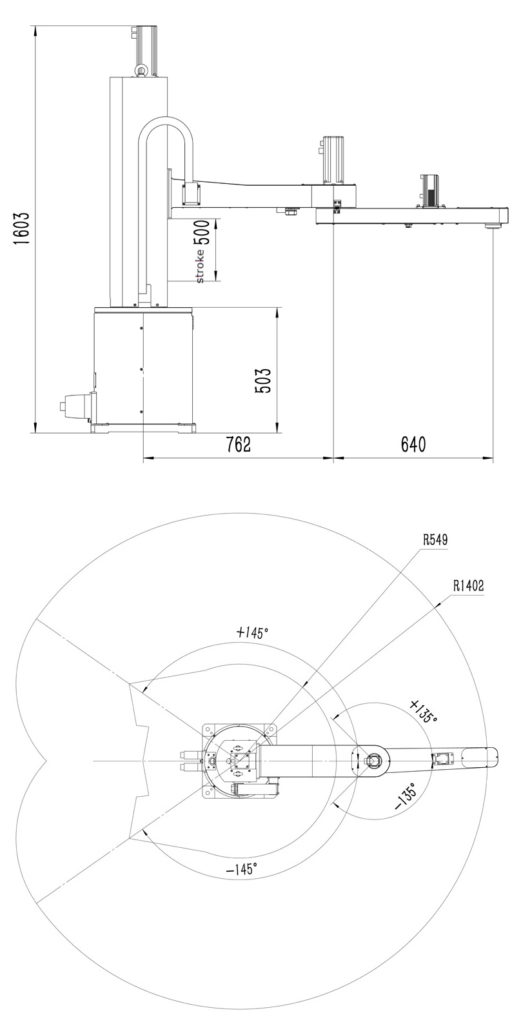

- High speed performance: using a low-speed ratio and high-precision reducer, the running speed is twice that of the same payload level of 6-axes robot.

- High precision: using the high-precision RV reducer with the repeatable positioning accuracy of ±0.05mm.

- High integration: there are almost no external wiring, which greatly reduces the probability of pipeline damage and can be used in hard working condition.

- High rigidity: high-strength cast iron and cast aluminum for the key structural parts ensure high rigidity of the metal stamping robotic arm when it works with fast speed.

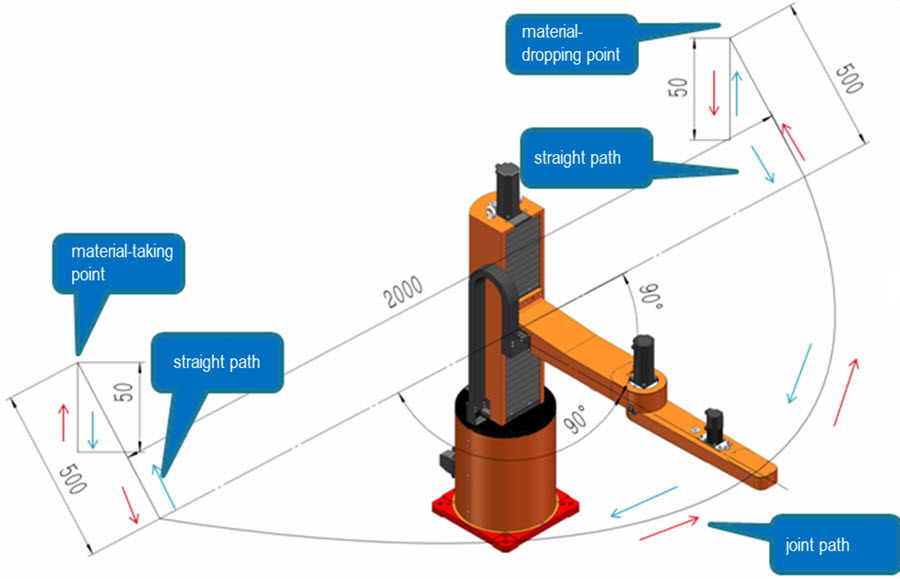

- High smoothness: the advanced control system and servo drive system are used to achieve high-speed and smooth motion performance, and the transition point is almost zero-time pause.

- High payload capacity: the maximum load of the wrist is 10kg, which can cover large workpieces and easily respond to new business orders from customers.