RBR5110 is developed for clients who need of small application field, high tempo, and cost-effectiveness. It is especially suitable for efficient stacking and handling operations where wrist joint freedom is required. As a domestic product, its maximum joints’ speed has reached the same level as KUKA’s counterpart product (KR120 R32200PA), which has high-cost performance and competitiveness in the market.

RBR5110 Five-axis Palletizing Robot Features

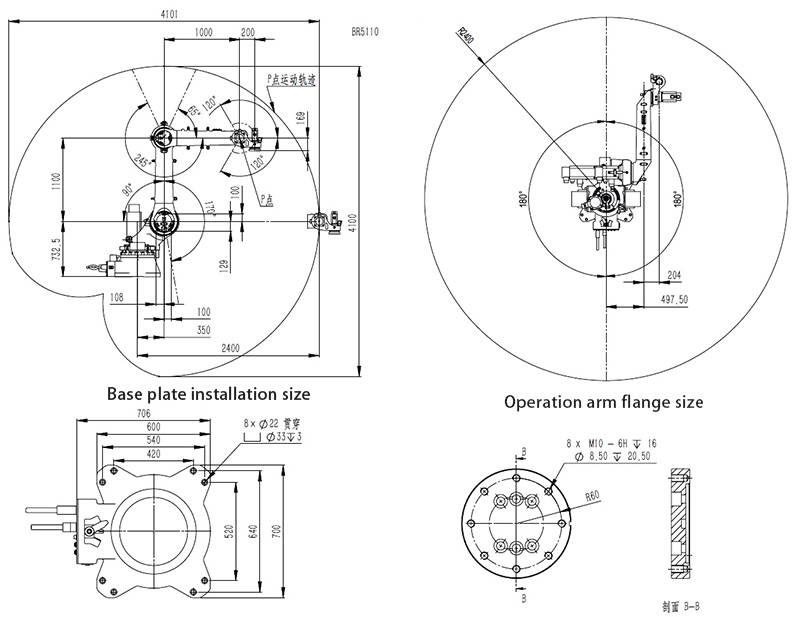

1: Unique double-rotation structure. Compared to the external rotary motion of a general-purpose robot, the BR5110 inherits the unique double-rotation configuration (outer rotation and internal rotation) of the BR series robot. The internal rotation mode allows BR5110 largely wires up or transport between stations under limited space because the BR5110 occupied a limited base area and the outside space is not occupied while moving.

2: 360°Full coverage. The BR5110 achieves 360° full coverage within a 2.4 m radius.

3: Flexibility. Compared to the traditional four-axis palletizing robot which can only handle the target handling operation in a single posture, the wrist joint added in BR5110 can achieve the grasping and placing actions in various postures.

4: Efficient. The BR5110 is faster than conventional robots with a unique dual-rotation design and high-speed motor configuration.

5: Convenient and easy programming operations. The BR5110 comes with a palletizing process package for simpler and more understandable programming, which can help with setting up the palletizing type instantaneously.