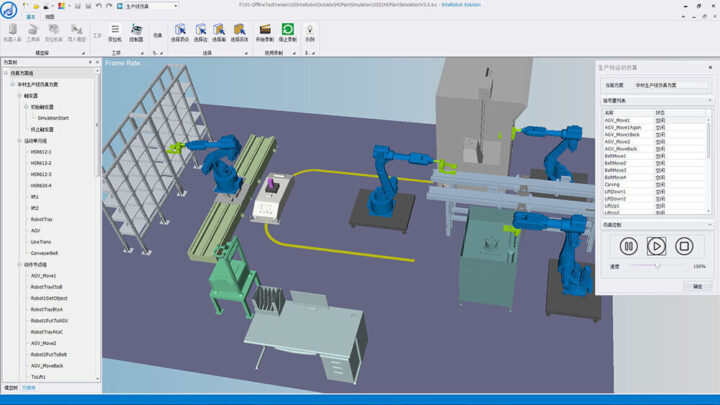

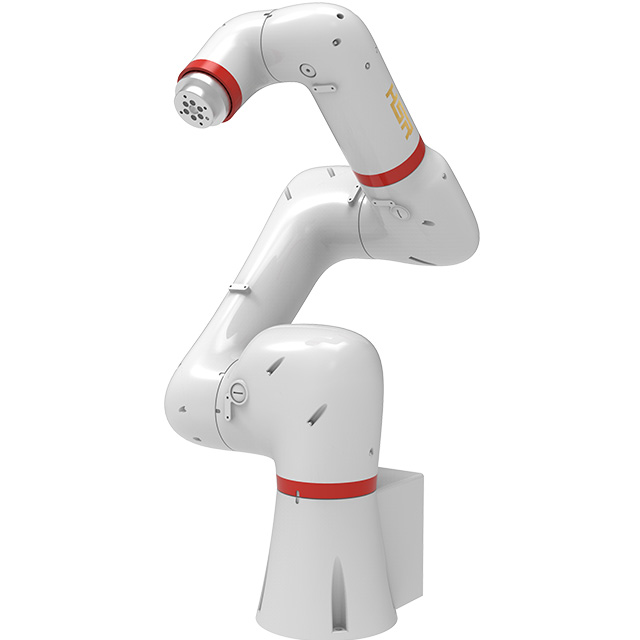

Collaborative robots, or cobots, are designed to work alongside humans in various industries, enhancing productivity, precision, and safety. Here are some key industry areas where cobots are commonly used:

1, Manufacturing:

Assembly: Cobots can perform repetitive tasks such as screwing, fastening, and assembling parts.

Material Handling: They assist in moving, sorting, and packaging materials.

2, Automotive:

Welding: Cobots can perform precise welding tasks.

Painting: They ensure consistent and even application of paint.

Handling: Cobots handle components on production lines, reducing the risk of human error.

3, Electronics:

Handling and Testing: Cobots handle delicate printed circuit boards and conduct tests.

Soldering: They perform precise soldering of electronic components.

Assembly: Cobots assist in assembling small electronic devices.

4, Logistics and Warehousing:

Picking and Placing: Cobots pick and place items in warehouses.

Sorting: They sort packages for shipping.