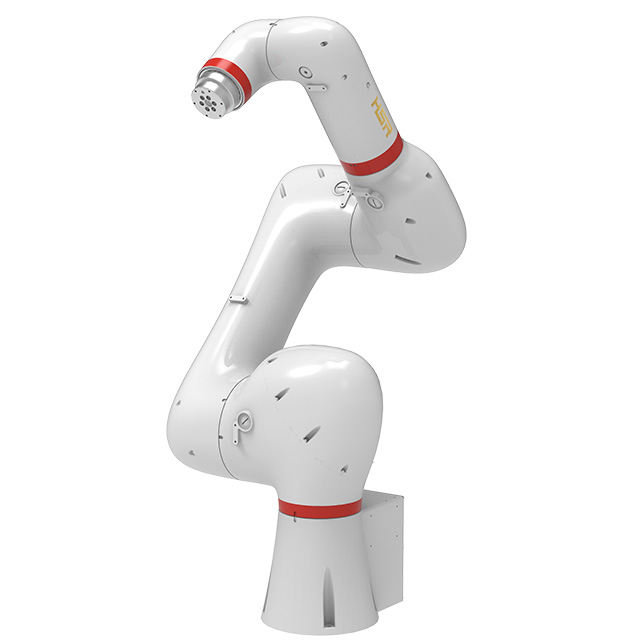

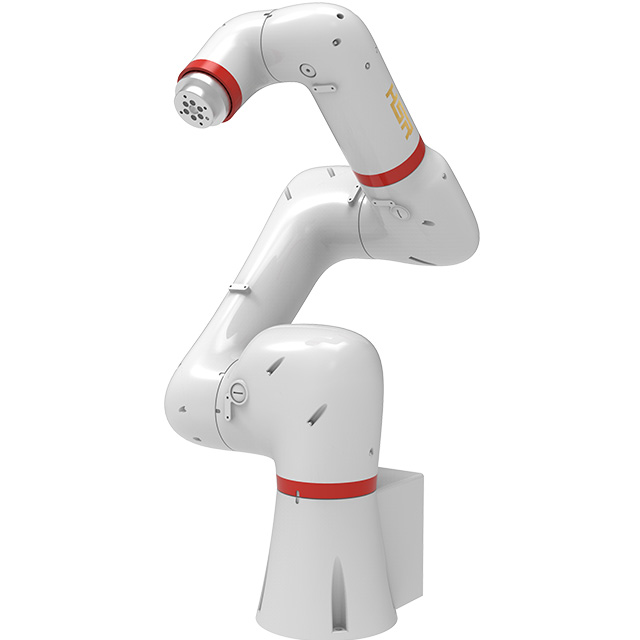

Because the cobot arm has their flexibility, ease of use, and enhanced safety features, and the cobots can be easily programmed and reprogrammed to adapt to changing tasks and production requirements. so the cobot robot can be used in various application area.

Assembly: Cobots are used in assembly lines to perform tasks such as screwing, fitting, and assembling parts. Their precision and consistency improve the quality and efficiency of assembly processes.

Material Handling: Cobots handle materials, components, and finished products, including tasks like picking, placing, sorting, and packaging. They help in reducing the physical strain on human workers and increase the speed of material handling.

Quality Inspection: Cobot robots equipped with cameras and sensors can perform quality control checks, inspecting products for defects or deviations from specifications. This ensures high product quality and reduces the likelihood of defects reaching customers.

Machine Tending: Cobots can load and unload machines such as CNC machines, injection molding machines, and others. This automation reduces downtime and increases the overall productivity of the manufacturing process.

Welding and Soldering: Cobots are used for precise and consistent welding and soldering tasks. They can perform these tasks in environments that may be hazardous for human workers.

Painting and Coating: Cobot arms are used to apply paint and coatings uniformly on various surfaces. They ensure consistent application and can work in environments with harmful fumes, reducing risks to human workers.