Our DT803 delta robot arm is widely used in robotic picking and placing systems for sorting different types of objects such as spoon sorting, PCB circuit board sorting, button battery sorting, logistics product sorting, etc. The below videos share the successful application cases of the DT803 delta robot for pick and place purposes.

The DT803 is suitable for fast sorting or boxing in various industries, integrated intelligent visual recognition, and good dynamic tracking. The 3KG load can meet most products that require fast sorting. DT-Catch software integrates visual settings, tool settings, The track setting, palletizing module, and the calibration module are integrated to simplify the operation process so that users can change the program they need at any time. Mature motion control technology ensures the stability of the robot system. The key moving parts adopt imported mature brands to ensure the service life.

RDT803 Delta Robot Pick and Place Characteristics

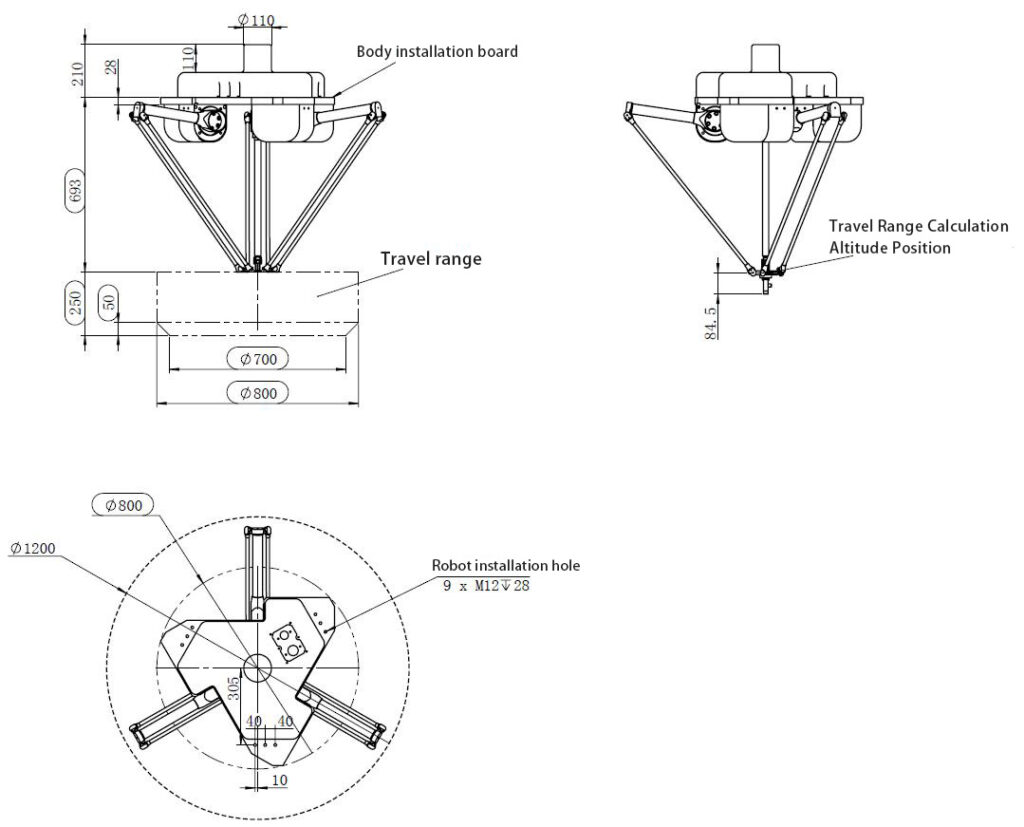

1. Precise positioning: Repeat positioning accuracy is up to 0.1 mm.

2. Visual Intelligent Recognition: The robot comes with a vision system that recognizes and accurately locates the shape, features, and posture of the target.

3. Conveyor dynamic tracking: Dynamically capture the target of visual recognition, greatly improving the efficiency of capture.

4. High speed: No-load grabbing beat can reach 140 times/minute (span 400 mm).