Huazhong 8 CNC system operation guide (Two)

Program and verification

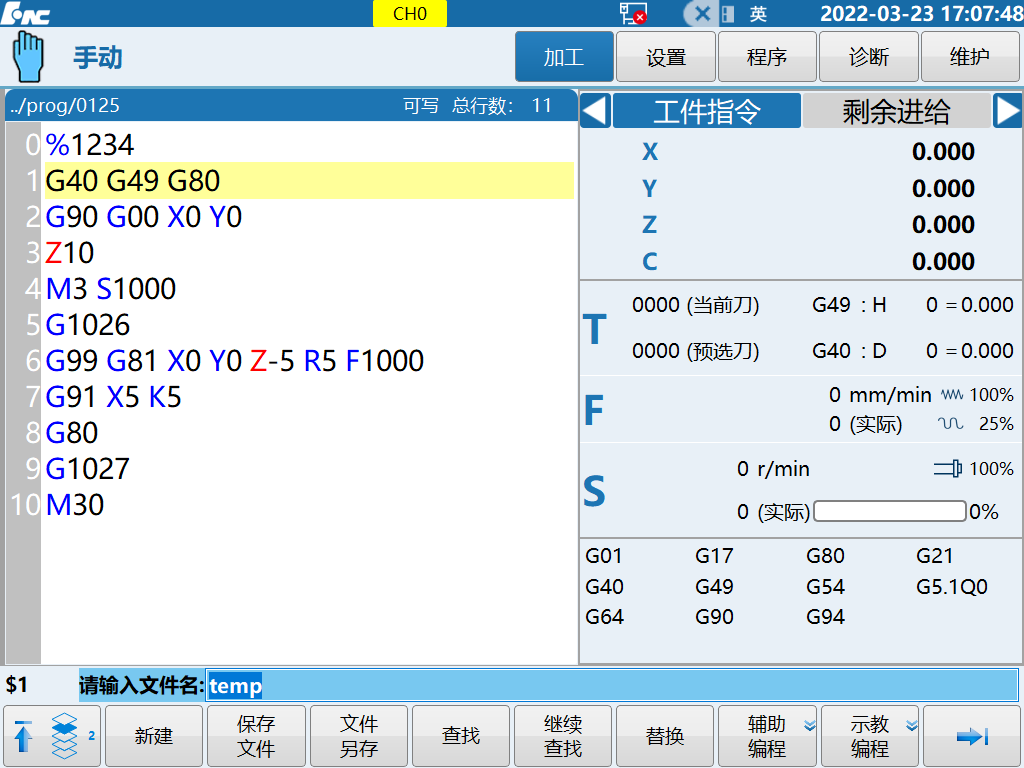

1, Create a new program

On the “Processing” function page, select the “Edit Program” soft key to enter the “Edit Program” sub-interface; In the sub-interface, press the “New” soft key, and the input field will ask you to enter the file name: “temp” (numbers or letters); press the “OK” key to confirm the new file name, and then enter the program edit area (if you want to exit this interface, you can press the “Reset” key)

After the program is written, press the “Save File” soft key, and it will prompt “Save the file is complete”. If it is not saved, return or “Reset” will automatically save it. (After the new program is held under the “Processing” function page, it will be automatically loaded as the current processing program.)

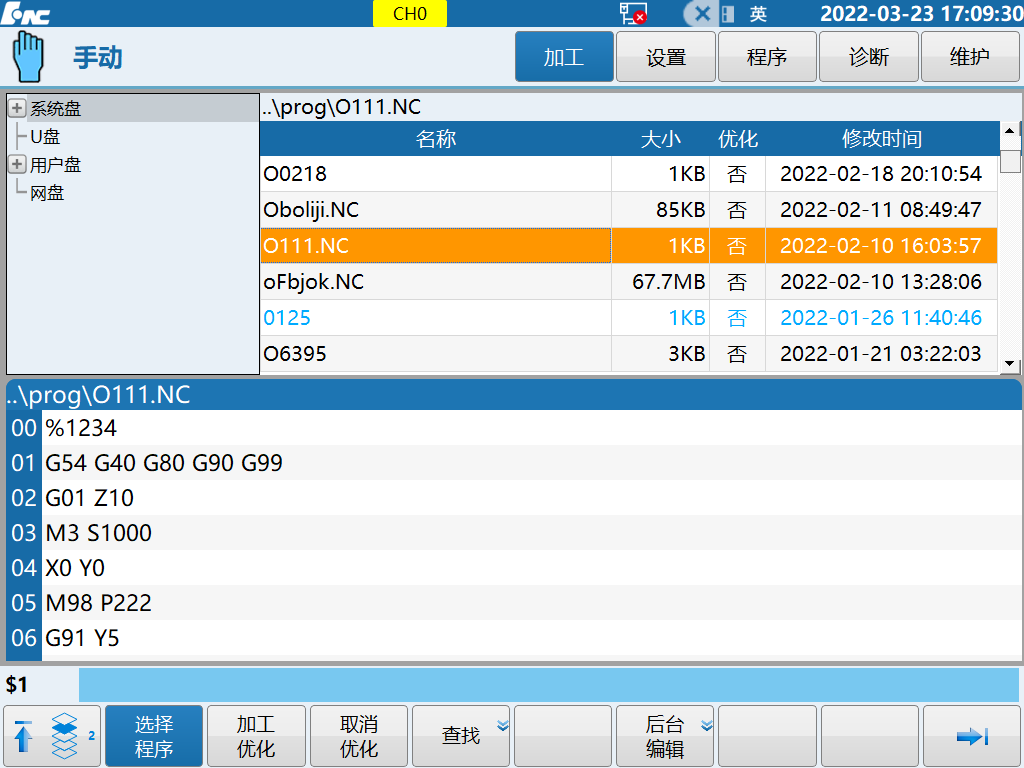

2, Select the program

Press the “Select Program” soft key to enter the “Select Program” sub-interface;

Select the source disk of the program, that is, the system disk, U disk, user disk, network disk, press the right arrow key to enter, select the target program, and press the “OK” button to load the processing program;

If you need to modify the program, press the soft key “Edit Program” to enter the “Edit Program” sub-interface;

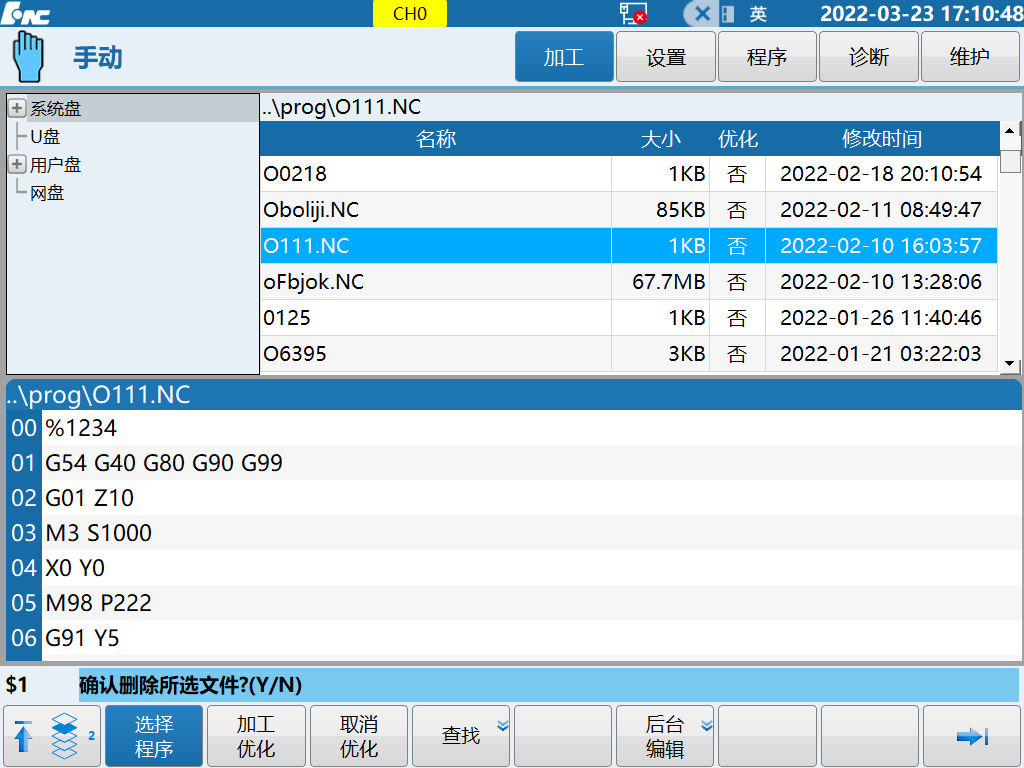

3, Delete the program

Function description: user program management function

Function content: Edit new program, select, copy, paste, delete the program from the system disk, U disk, network disk, program rename, sort, and set the mark.

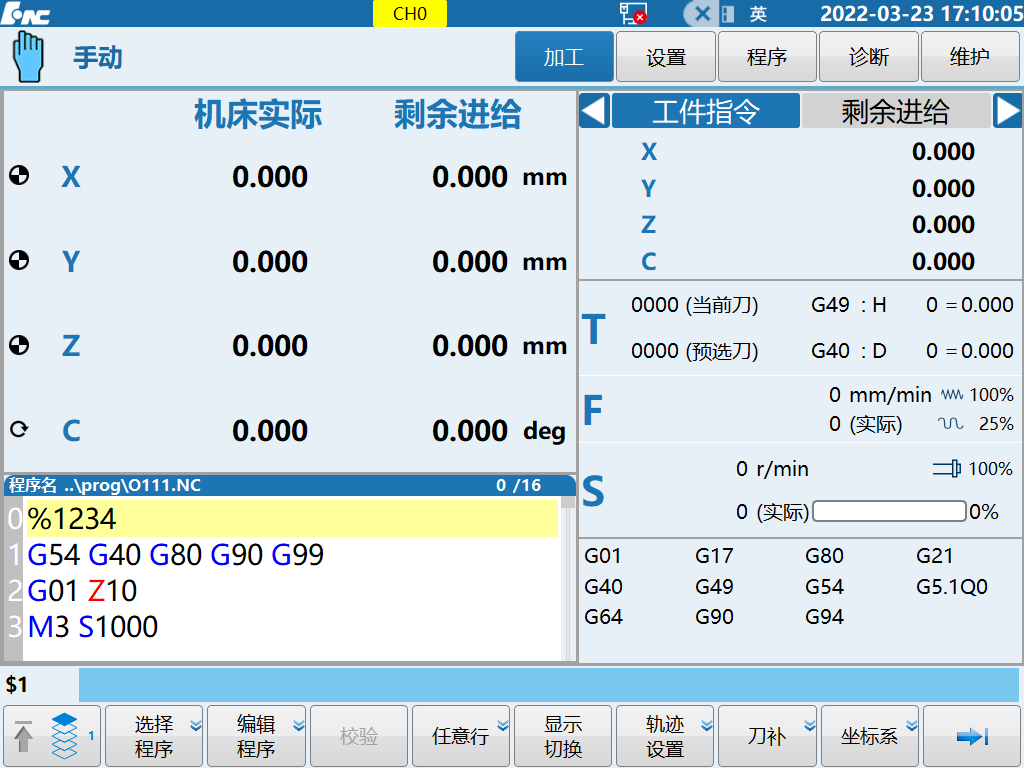

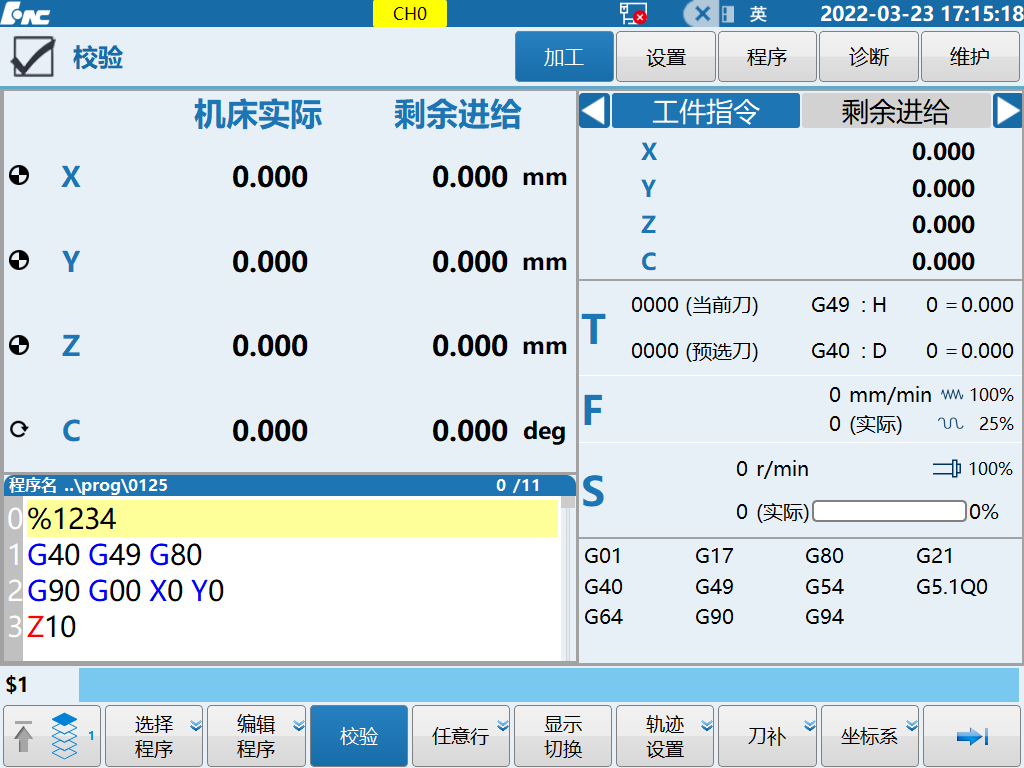

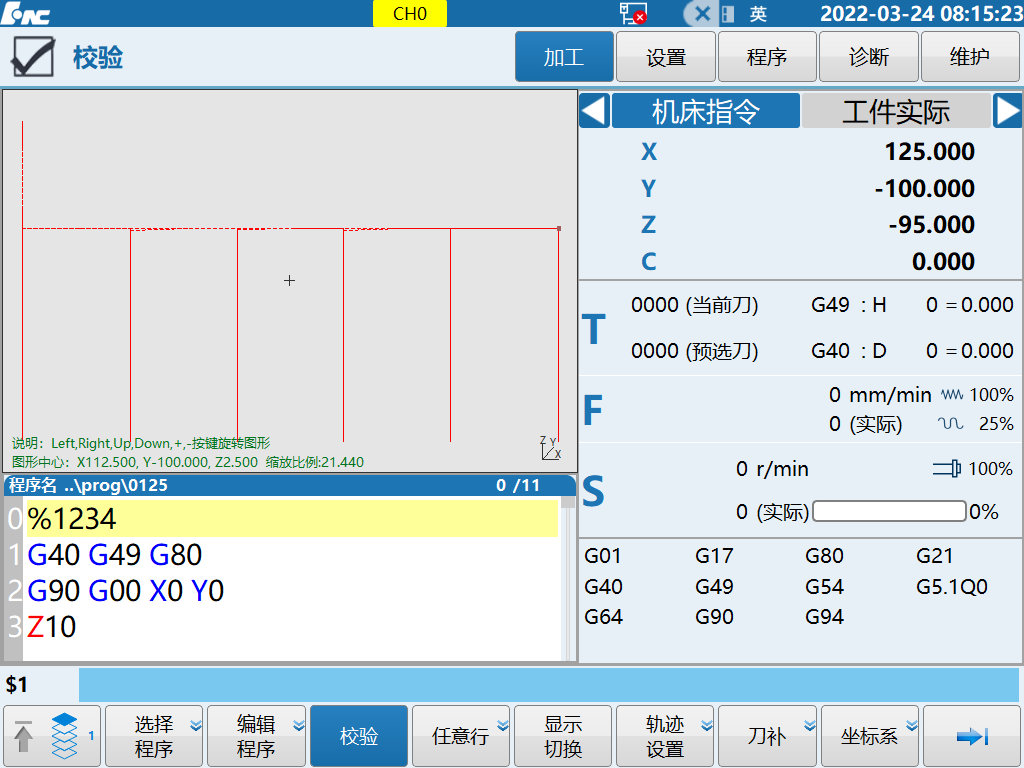

4, Program verification

It is valid in automatic and single-segment working modes. After pressing the soft key “Verify”, the display of the working method will change from “Auto” to “Verify”.

Press the “Display Switch” soft key to switch among the four display modes of “big coordinates, union, graphics, and text”. Switching to the “Graphic” display mode is convenient for observing the program track, and entering the graphic operation interface through the “Track Setting” soft key can change the graphic and check and verify the program track.

Press the [Cycle Start] key to start verifying the program, and the system quickly simulates the tool path trajectory in the program. The machine tool is stationary during the simulation process, so it is fast and safe to use this method to check whether there are obvious errors in the program.

Please stay tuned for the Milling CNC Quick Start Operation Guide Series

Issue 1 Overall Introduction to Panel Functions

Issue 2 Program and verification

Issue 3 Machining coordinate system setting

Issue 4 Manual MST (manual numerical command)

Issue 5 MDI Function (Manual Input Mode)