Huazhongcnc upgrades high-speed, high-precision, and efficient machining technology of turning CNC system series.

With the diversified needs of the lathe CNC market, the diversified needs of models, the needs for convenient debugging and application, the needs for customer customization, and the needs for digital network management, the Huazhongcnc turning CNC system is upgraded to help users improve the quality of parts processing, improve processing efficiency, and provide users with the best solutions! HNC upgrades high-speed, high-precision, and efficient machining technology of turning CNC system series.

1, High-resolution encoder

The full range of low-voltage LMDD series and high-voltage HMDD series motors are equipped with 16 million lines of high-resolution photoelectric encoders as standard, which improves the accuracy and finish of processing.

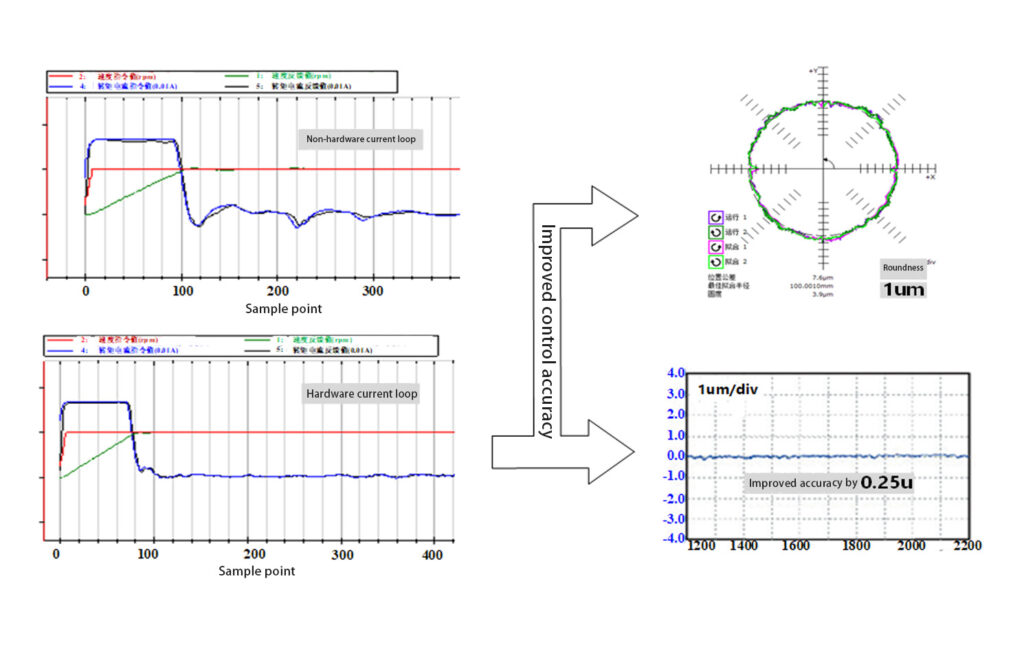

2, Hardware current loop

The high-performance drive adopts hardware current loop, notch, over modulation, field weakening, and other technologies to significantly improve the current loop response characteristics and servo control stiffness and response.

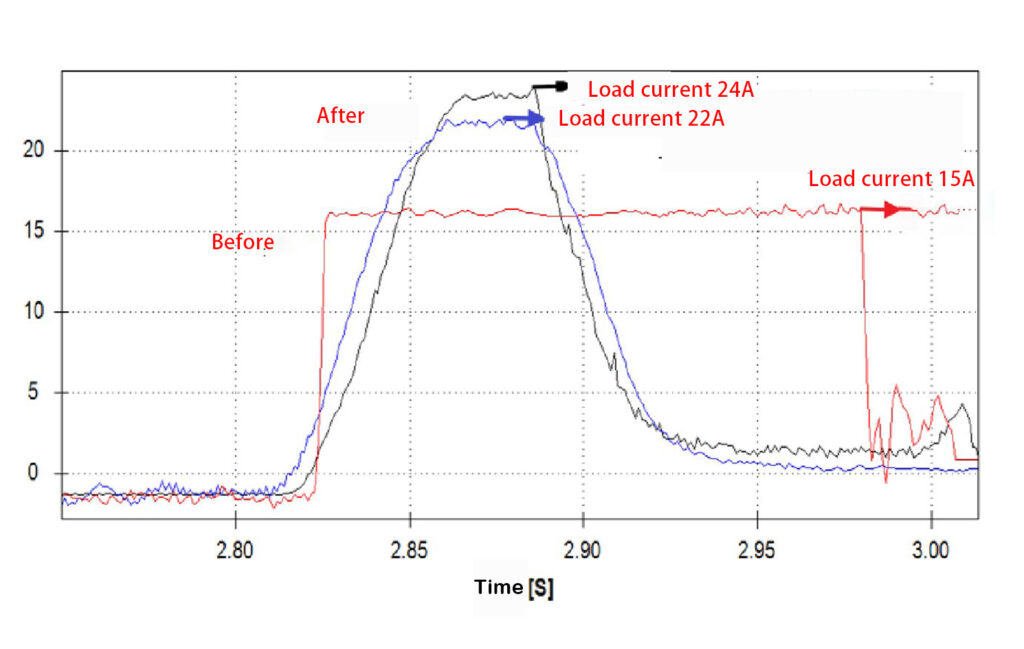

3, Notch and vibration suppression filter

- Improve the notch trap function, reduce the current and acceleration attenuation caused by the notch when the notch is turned on, and ensure high acceleration and high response of the machine tool while suppressing vibration.

- Add a vibration suppression filter and notch to suppress low and high-frequency vibration of the machine tool. Suppress the vibration and abnormal noise under the high gain of the machine tool, effectively reduce the fluctuation range of machining tracking error, and improve machining performance.

| Version | Before | After | |

| Function | Vibration suppression frequency | ||

| Notch | √( The current attenuation is more than 30%) | √( The current attenuation is within 5%) | >600Hz |

| Vibration control filter | × | √ | ≤600Hz |

4, High finish, no quadrant lines

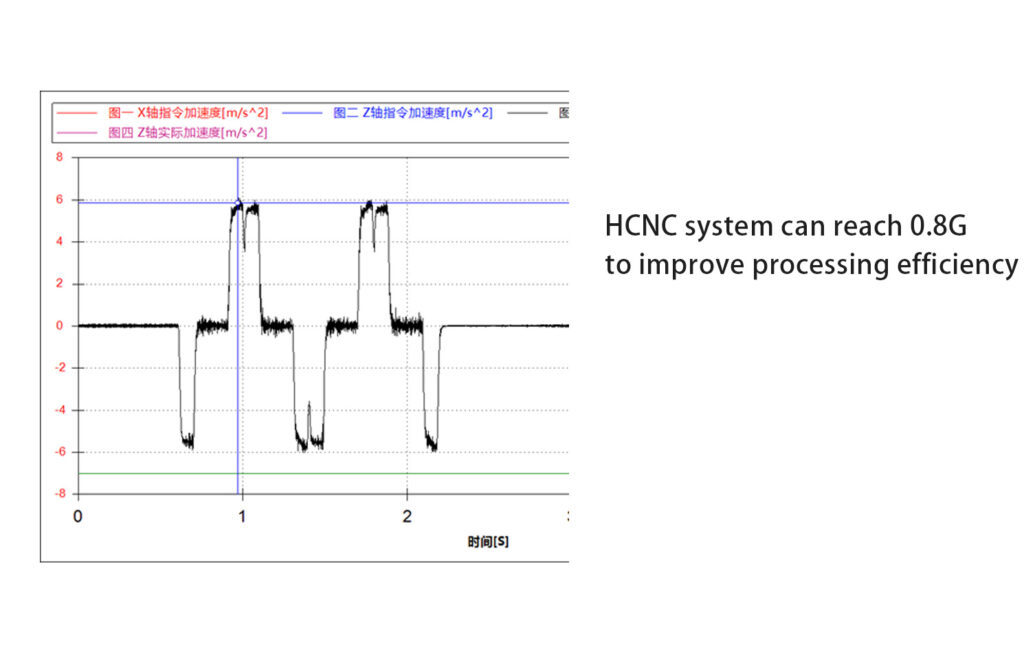

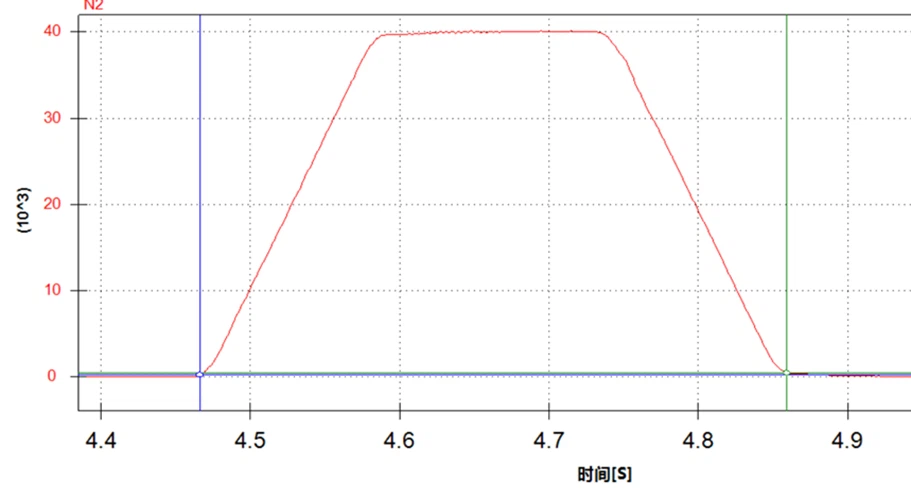

5, High acceleration and deceleration

In the lathe line rail processing layer cutting, tool change has many G00 retracts, the retraction distance is not long, and the processing time is immutable, and the G00 with high efficiency and high acceleration and deceleration directly affects the processing efficiency. At present, the Huazhongcnc system can reach 0.8G.

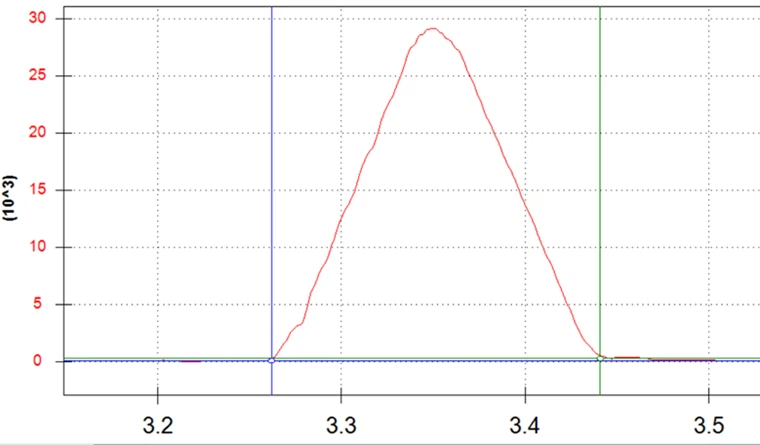

6, High-speed servo tool change

| Close Tool change time T1→T2 | Remote Tool change time T1→T5 |

| 0.179 second | 0.393 second |

| Close Tool change time T1→T2 | Remote Tool change time T1→T5 |

| 0.180 Second | 0.4 Second |

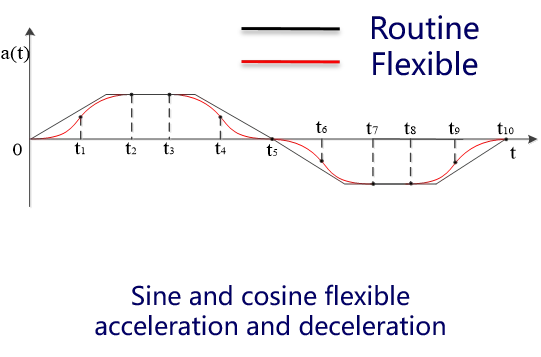

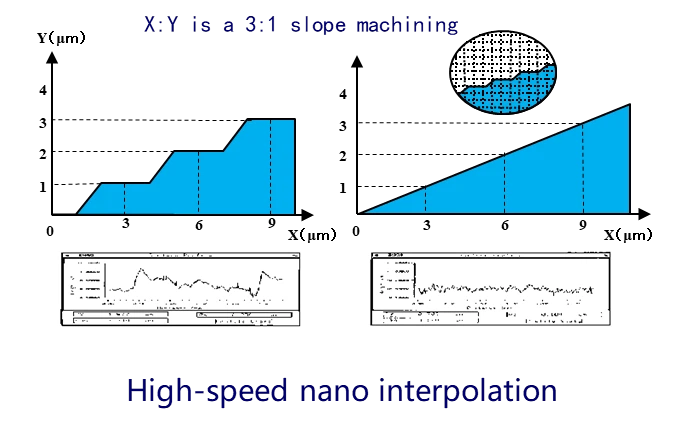

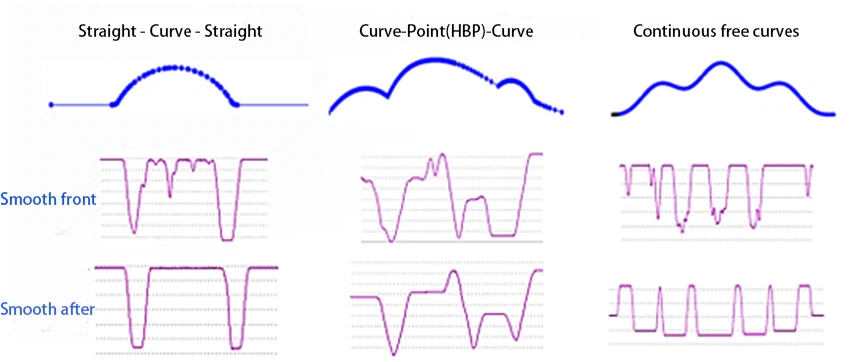

7, High-speed and high-precision control algorithm

(1)The program pre-reads 2,000 paragraphs ahead of time

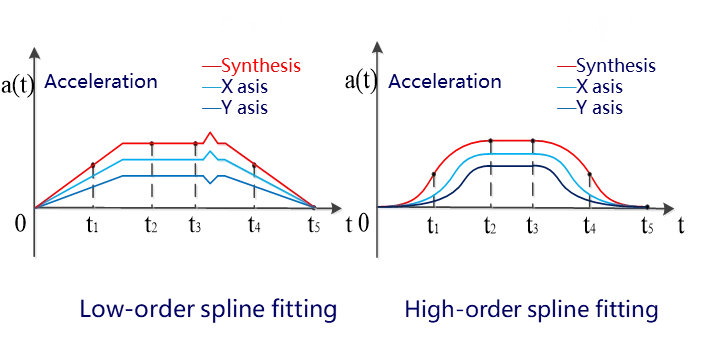

(2)Sine and cosine flexible acceleration and deceleration control

(3) High-speed nano interpolation

(4) High-order fitting of small-segment trajectories

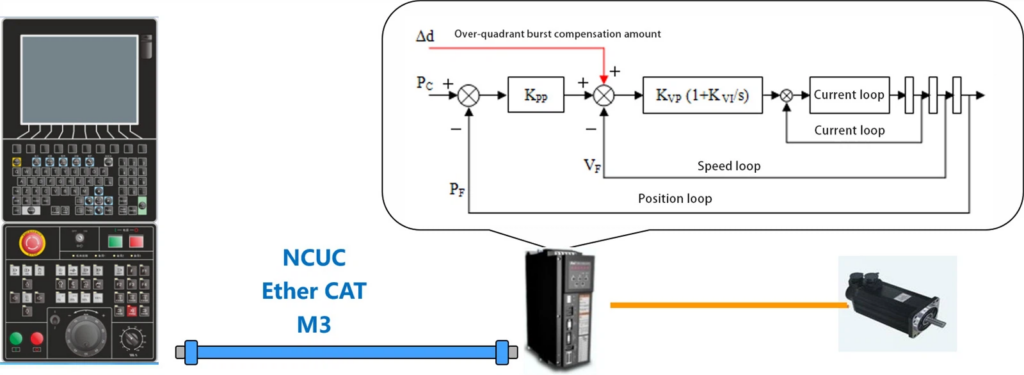

8, Over-quadrant burst compensation

The speed compensation model is established to compensate the servo for speed when the axes are reversed, offsetting the effect of frictional hysteresis, eliminating quadrant tool patterns, and improving the surface quality of surface machining, which is widely used in consumer electronics, molds, and five-axis simultaneous machining.