How can efficiency and quality be improved in wheel hub processing? HiCNC’s comprehensive solution makes a significant impact.

Series Highlights: In the previous installment, we discussed the rapidly growing wheel hub processing market, along with innovations in materials and technology. This time, we will concentrate on HiCNC’s core technologies in wheel hub processing, highlighting how technological innovation leads to significant improvements in both processing efficiency and precision.

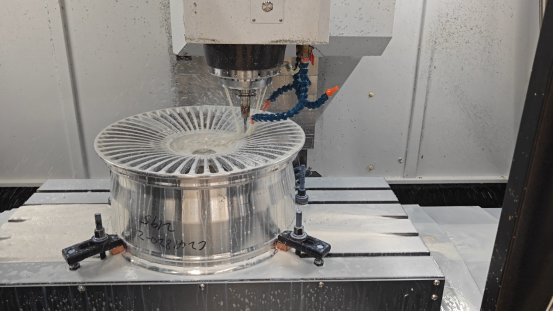

The Requirements of CNC Equipment for Processing Wheel Hubs

The processing of automotive wheels involves three key steps: the first step uses a lathe for positioning and cutting to remove burrs; the second step uses a machining center to achieve high-precision forming of bolt holes and valve holes; and the third step, based on the first step’s benchmark, uses a CNC machine tool to complete the final dimensional finishing. Each step requires CNC equipment to achieve micron-level precision control and complex trajectory planning, placing stringent demands on the multi-axis linkage and dynamic response capabilities of the CNC system.

The processing of automotive wheels involves three key steps:

- The first step uses a lathe to position and cut the material, effectively removing any burrs.

- The second step employs a machining center to precisely form the bolt holes and valve holes.

- The third step, which builds on the benchmarks set in the first step, utilizes a CNC machine tool to complete the final dimensional finishing.

Each of these steps relies on CNC equipment to achieve micron-level precision and complex trajectory planning. This places stringent demands on the multi-axis linkage and dynamic response capabilities of the CNC system.

More Precise, Faster, and Smarter: HNCs’ Technological Applications in Wheel Hub Machining

1. High-Speed Machining Solution-Adaptive Feed Rate Control (AFC)

| Feed Adaptation | Off | On | Efficiency Improvement |

| T1(large spoke roughing) | 40min | 35min | 12.5% |

| T2(small spoke roughing) | 65min | 58min | 10.8% |

| T3(small spoke roughing) | 76min | 70min | 8.6% |

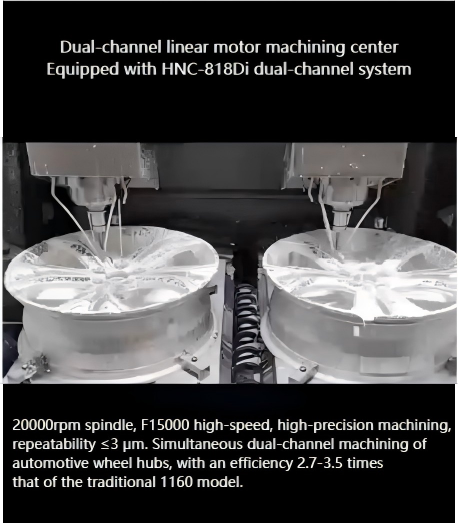

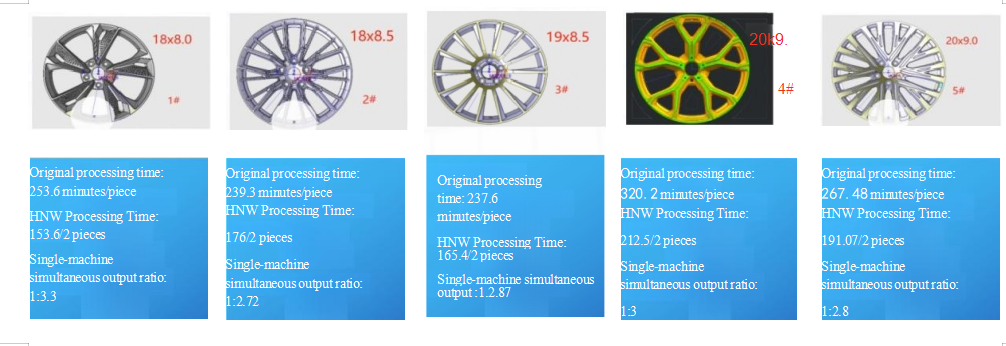

2.Multi-axis, multi-channel control technology:

The HiCNC-818Di multi-axis, multi-channel control system is designed to meet the complex machining processes and operational control requirements of CNC machine tools. It effectively addresses the challenges of multi-axis collaborative control in composite machining centers and flexible production lines. After integrating this system, the Yudongyuan dual-channel wheel hub machining center successfully achieved high-precision mass production of intricate components, including those for 5G base stations and wheel hubs.

- Dual-channel independent control, simultaneous machining with both heads.

- High machining efficiency, 2-3 times that of traditional machining centers.

3.Template-Based Process Parameter Optimization

By utilizing data acquisition and algorithmic analysis, we provide tailored parameter solutions that enhance machining efficiency by an average of 5% to 20% in mass production across industries such as aerospace and automotive manufacturing.

4. Linear Motor Applications

By utilizing high acceleration and nanometer-level resolution, Huazhong CNC’s linear motor solutions enhance hub machining speeds to 15,000 mm/min. This results in 2.7-3.3 times greater efficiency compared to traditional methods while also providing industry-leading surface quality and dimensional accuracy.

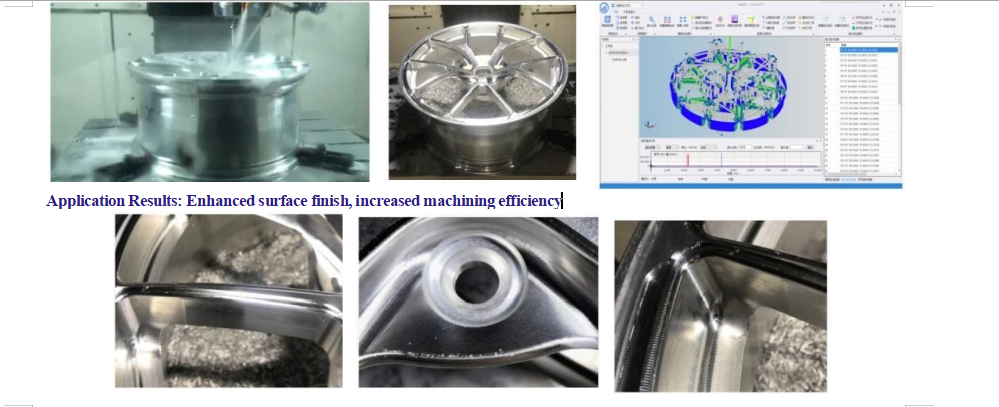

5. High-Precision Machining Assurance System

Ultra-Smooth Surface Interpolation Function:

In complex surface machining, trajectory smoothing algorithms optimize speed continuity. At high-speed milling rates of 8000 mm/min, this ensures stable global speed output, significantly improving the finish of wheel hub surfaces.

Integrating speed/acceleration feedforward compensation with friction disturbance observation, this feature boosts contour accuracy by 58% during R0.5mm small arc machining, ensuring dimensional consistency for complex surfaces.

Intelligent Operation & Maintenance System

- Full Lifecycle Management: Utilizing an enterprise-level data center, this system creates digital archives for machine tools. It enables predictive maintenance, intelligent scheduling of maintenance plans, and estimation of critical component lifespans. This shift transforms reactive repairs into proactive health management.

- Remote Diagnostic System: Using the NCUC bus for real-time device data collection, it enables remote fault diagnosis and program optimization, which effectively reduces downtime and enhances overall equipment utilization.