HNC 5-axis CNC system product package – RTCP automatic parameter calibration function

In modern high-end manufacturing, five-axis machining centers play a pivotal role in the efficient and precise shaping of complex curved surfaces. By leveraging their advanced capabilities, manufacturers can significantly enhance their overall production effectiveness and quality.

A key factor in enhancing the performance of five-axis machine tools is the RTCP (Rotation Point Tracking) function, often referred to as the “hidden heart.” The RTCP parameters provide clear mathematical descriptions of the positions and orientations of the rotary axes as defined by the CNC system. By ensuring these parameters are accurately calibrated, users can address potential issues that might arise. Variations in these parameters can lead to challenges such as distorted machining contours and reduced surface quality or even more serious risks like machine collisions. Thus, focusing on the rapid and precise calibration of RTCP parameters can significantly improve the accuracy of five-axis machining. This ongoing improvement presents an opportunity for users to enhance their machining processes and achieve greater reliability and efficiency in their operations.

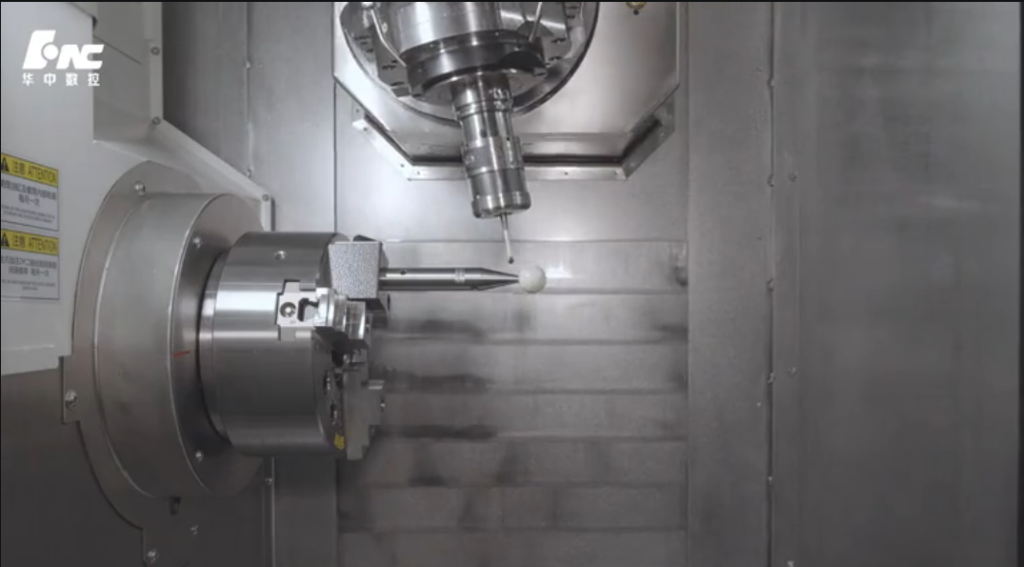

Traditionally, manual calibration has relied on tools like dial indicators and gauge bars, which can be cumbersome, time-consuming, and dependent on the technician’s level of expertise. To overcome this challenge, automatic calibration functions that utilize probes and standard balls have become standard features in high-end CNC systems.

Introduction to the RTCP Parameter Automatic Calibration Function of HNC Five-Axis CNC System

The HNC 5-axis CNC system product package includes standard features such as RTCP automatic parameter calibration. It is compatible with popular 5-axis machine tool structures, including dual rotary tables, dual swivel heads, and hybrid swivel-rotor setups. The design of the function incorporates a guided interface, which simplifies complex parameter settings and measurement processes into clear, visual operations. This approach reduces the barrier to entry for users while enhancing calibration efficiency and accuracy.

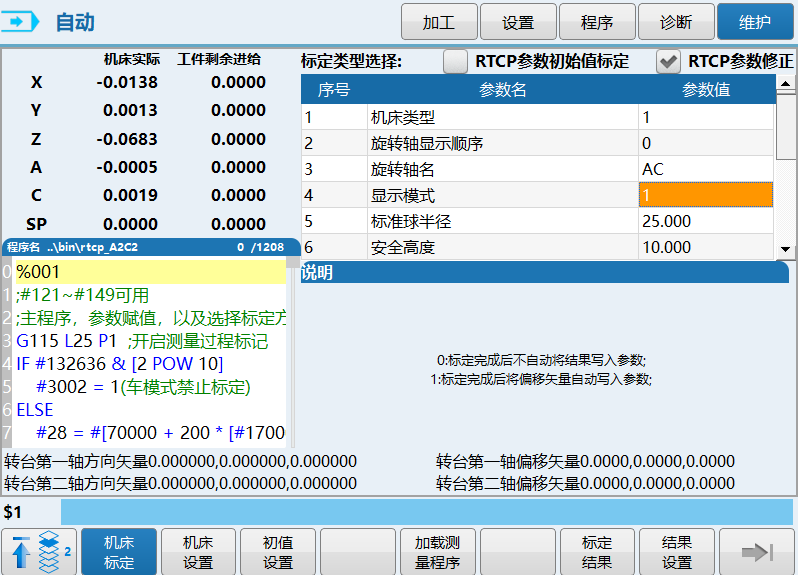

When using the automatic calibration function for the first time, users need to configure both the machine tool structure and measurement parameters. Please follow these steps:

1. Machine Tool Settings: In the system interface, select the type of machine tool calibration, the 5-axis structure type, and the names of the rotary axes. For example, for the most common 5-axis structure, the AC cradle dual rotary table, set the calibration machine tool type to 1, the rotary axis display order to 0, and the rotary axis name to AC, ensuring that the rotary axis is listed first.

2. Measurement Parameter Settings: In the calibration interface, set the parameters sequentially: standard ball radius, safety height, measurement speed, reference angle, as well as the start and end angles and the number of measurement points for each rotary axis. Setting the reference angle helps prevent accidental touches that may occur due to different placements of the standard ball. The start and end angles of the rotary axis and the number of measurement points can be adjusted to align with the travel range of the machine tool’s rotary axis. Additionally, the calibration time can be controlled by changing the number of measurement points.

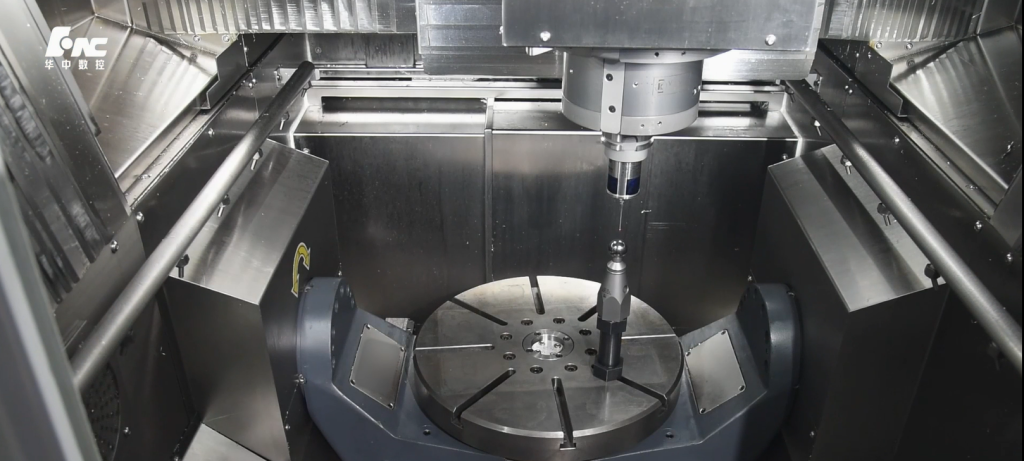

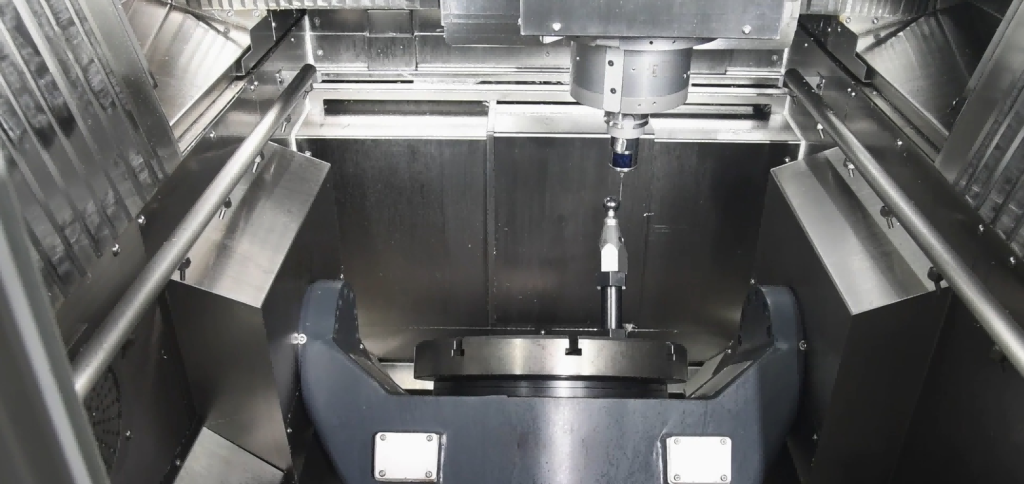

3. Loading and Running: Once the parameters have been confirmed, the system automatically loads the calibration macro program. The user should position the probe approximately 10mm above the center of the standard ball and then start the cycle machine to initiate automatic measurement.

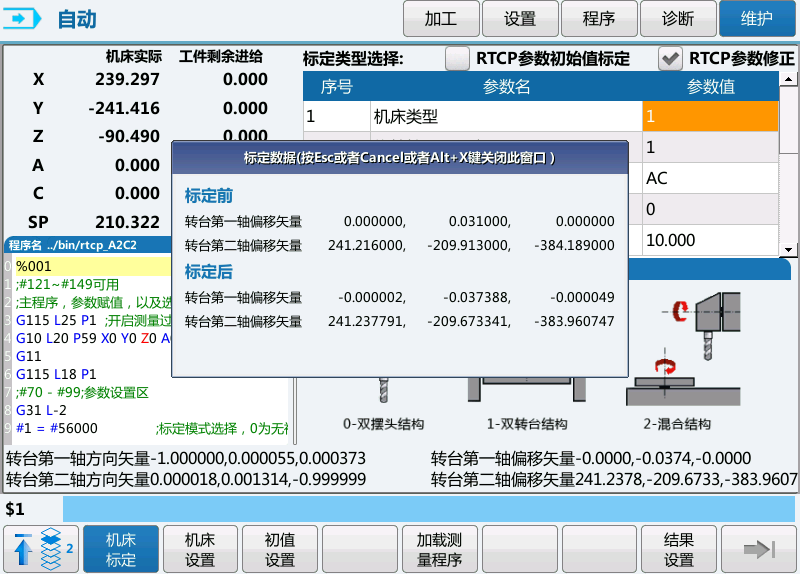

4. Result Setting: After measuring, the system automatically calculates and displays the calibrated rotary axis position in a pop-up window. The calibration results are then automatically recorded in the system.

After the initial automatic calibration of RTCP parameters, periodic calibration or adjustment during daily use and maintenance is straightforward:

- Quick Start: Begin by accessing the calibration interface. Position the probe approximately 10 mm above the center of the standard sphere using the existing parameters.

- One-Click Calibration: Load the program and start it; the system will automatically measure and calculate the necessary adjustments.

- Result Display: The new calibration results will be displayed in a pop-up window, allowing comparison with the existing RTCP parameters. Once you confirm their accuracy, a single click updates the parameters and restores the machine tool to its optimal accuracy.

Application Results

The automatic calibration function for RTCP parameters on five-axis machines has been applied to three mainstream five-axis structures. Compared to manual calibration, the calibration efficiency has been reduced to 5 minutes, and the calibration accuracy is ≤0.02mm.

Conclusion

The automatic calibration function for RTCP (Rotational Tool Center Point) parameters in HNC five-axis CNC systems is revolutionizing the assurance of precision in five-axis machining. This innovative technology transcends traditional manual calibration methods, which often depend heavily on the technician’s expertise and intuition. Instead, it introduces an intelligent, automated calibration process that is guided by advanced visualization techniques.

This evolution significantly alleviates the time-consuming and often cumbersome challenges associated with conventional calibration methods, effectively lowering the barrier to achieving exceptional precision in machining operations. The automatic calibration seamlessly integrates with a variety of mainstream five-axis machine tools, including those equipped with dual rotary tables, dual swivel heads, and hybrid structures. Moreover, its design features a user-friendly one-click verification system, simplifying the process and making high-precision machining more accessible than ever before.

Accurate RTCP (Rotational Tool Center Point) parameters act as the essential “precision core” of five-axis machine tools, playing a pivotal role in ensuring the machining quality of complex, curved surface parts. This automatic calibration function not only lays a robust foundation for achieving high-precision production in the manufacturing sector but also significantly boosts the efficiency and reliability of five-axis machining processes. Consequently, it facilitates the evolution of high-end manufacturing toward greater levels of intelligence and operational efficiency, all while meticulously safeguarding the intricate machining processes involved in crafting sophisticated components. This advancement is vital for meeting the increasing demands for precision in modern manufacturing applications.