Features of HNC808Di/M Open Source CNC Controller for Grinding Machines

- 2-4 axis control

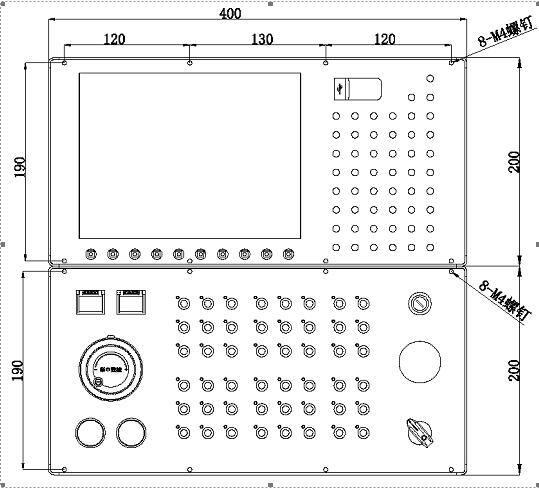

- 10″ color LCD screen

- External PLC & IO module

- Support NCUC, M3, Ethercat bus protocol

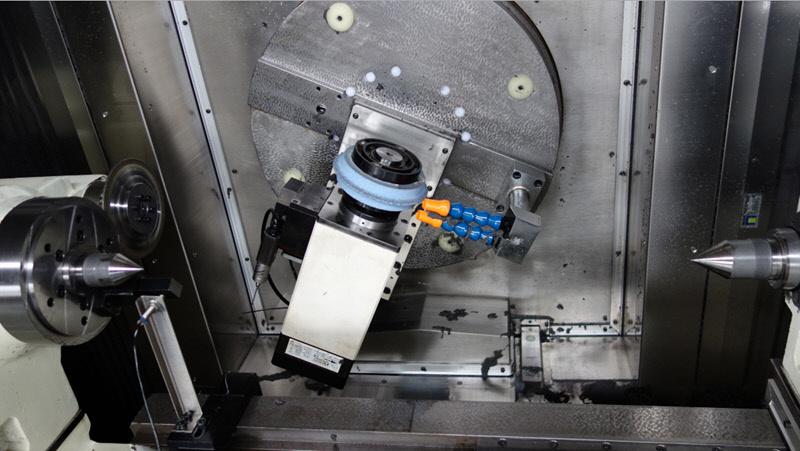

- Used for CNC grinding machine

Rich Application Scenarios

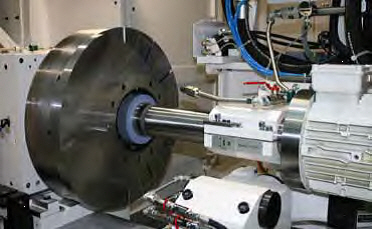

(1) Internal Grinding

-Oscillation grinding,

-High frequency, high efficiency,

-Accurate

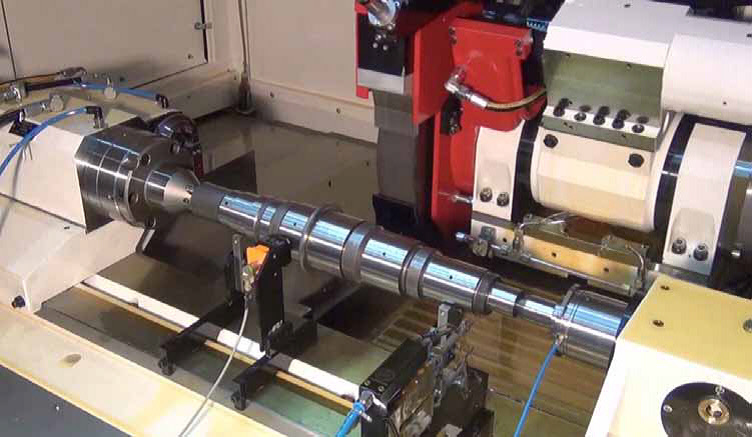

(2) Cylindrical Grinding

-Realize the grinding of various parts through a variety of grinding methods

-The process is optimized, and the grinding time is reduced by 30%.

-It can grind multi-step, long shaft and thin-walled workpieces.

(3) Centerless Grinding

-Plunge grinding, continuous grinding, plunge-continuous grinding

-Support online measurement

-High response, high speed, high precision

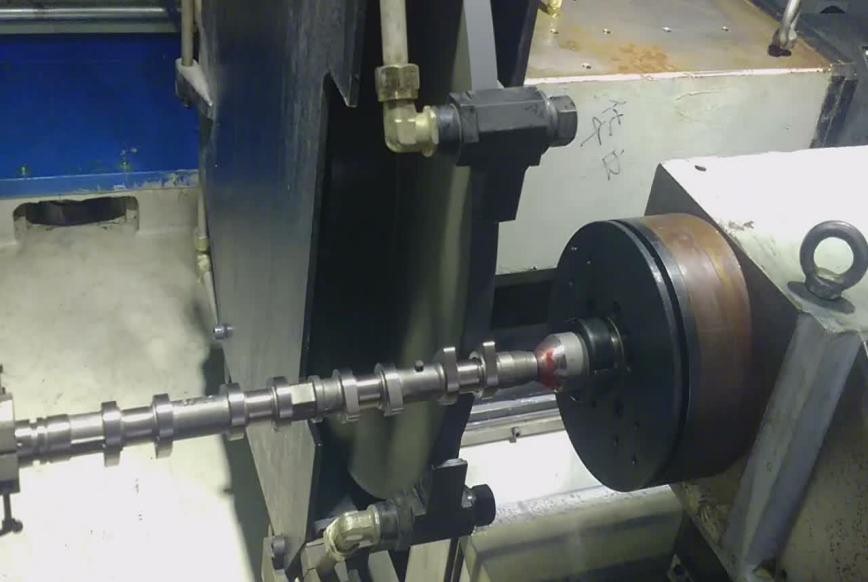

(4) Cam Grinding

-Ethercat protocol, fast response

-Horizontal speed control, high precision

-Optimized cam algorithm, high precision

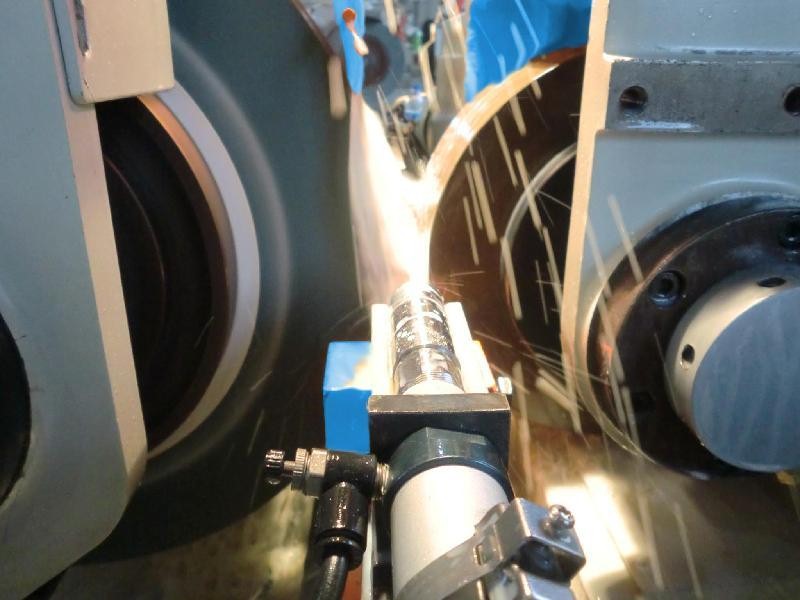

(5) Thread screw grinding

-Online monitoring, online compensation

-Convenient tool setting and high precision

-Optimize grinding solution

(6) Crankshaft

-Horizontal speed control, high precision

-Ethercat protocol, fast response

-Optimized tangent point following algorithm, high precision

-Error control and compensation

(7) Gear grinding

-Electronic Gear Box

-Support straight tooth, helical tooth and arc tooth processing

-Optimized control algorithm