AI and Intelligent Manufacturing: HNC’s Intelligent Solutions Empower the “Factory of the Future.”

As machine tools gain the ability to think, robots develop sensory capabilities, and production lines become “self-healing,” Huazhong Numerical Control is transforming the precision and intelligence associated with “Made in China.” The company is offering an intelligent closed-loop system that encompasses the “brain, hands, feet, and nerves” of manufacturing. This integrated solution provides the equipment manufacturing industry with intelligent control, execution, and support, enabling enterprises to create efficient, reliable, and flexible factories for the future.

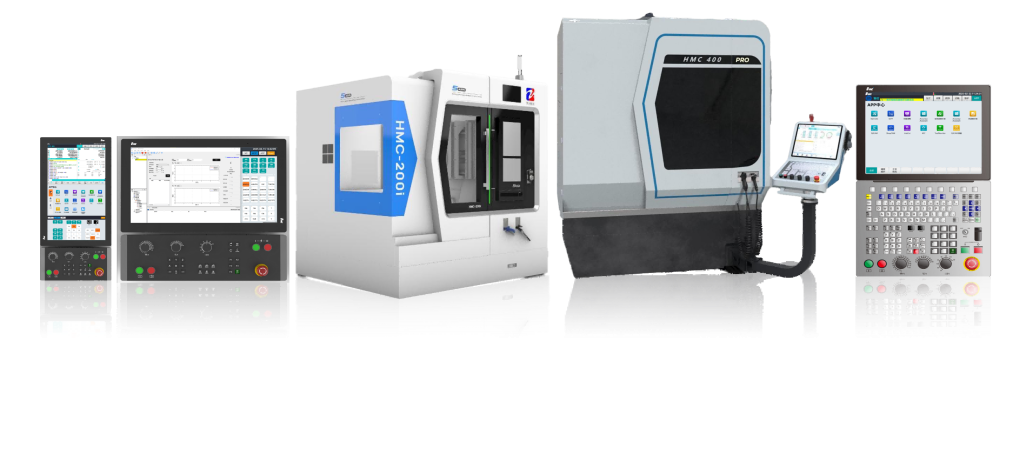

Advancing CNC technology from basic “digital control” to “intelligent digital control.”

The new generation of intelligent machine tools integrates cutting-edge artificial intelligence technology with advanced manufacturing techniques. Built on the foundations of the industrial internet, big data, and cloud computing, these tools are capable of autonomous perception, learning, optimization, decision-making, and execution. This integration significantly enhances the quality and efficiency of machining processes while reducing costs. These intelligent machine tools are a key product of the Fourth Industrial Revolution.

Driving the evolution of CNC systems from “closed systems” to “open ecosystems.”

Traditional CNC systems are often closed “black boxes,” with functions predetermined by manufacturers, which limits users’ ability to customize and further develop the systems to meet their specific process needs. In contrast, the Huazhong 10 creates a unified and open platform. Huazhong CNC provides access to its hardware interfaces, data interfaces, and operating platform for machine tool manufacturers, user factories, and third-party R&D institutions. This approach fosters an innovative ecosystem based on co-creation, sharing, and mutually beneficial collaboration. Additionally, in partnership with 18 machine tool companies, including Wuhan Heavy Machine Tool and Qinchuan Group, Huazhong has developed the world’s first batch of 20 intelligent CNC machine tools compatible with the Huazhong 10. This includes advanced intelligent five-axis machining centers and intelligent laser processing machines, marking a significant shift from “single-point breakthroughs” to “system integration.”

“Transforming CNC Production Organization from Isolated Information Silos to Integrated Systems Engineering”

The Huazhong 10 model establishes two digital main lines: the complete lifecycle of the machine tool and the full machining process of the parts. It combines a cloud-based big data center and intelligent platform, CNC devices, intelligent sensing modules, and other components into a digital transmission network that connects the edge, end, and cloud. This approach represents a significant advancement from “information silos” to “systems engineering.”

Embossed Intelligent Robot Solutions

As the manufacturing industry transitions towards advanced, intelligent, and sustainable development, optimizing algorithms—such as deep learning and reinforcement learning—and integrating multimodal perception technologies have become significant trends. Huazhong CNC has developed embossed intelligent industrial robots that incorporate vision, force control, and various multi-sensor devices. These robots excel in intelligent collaborative tasks like grasping, handling, and assembly operations within large-scale unstructured environments. They are suitable for industrial applications across sectors, including consumer electronics, automotive, and medical fields, as well as in education and scientific research.

Multimodal Perception: In-Depth Understanding and Accurate Positioning

Embodied intelligent industrial robots are equipped with a multimodal fusion perception system that integrates auditory, visual, and force control. This system enables the robots to achieve deep perception and dynamically adapt to their environment.

A 3D camera conducts a comprehensive scan, accurately analyzing the shape and size of objects for coarse positioning. Additionally, the voice recognition module understands human language and converts it into program instructions for the robot. This functionality allows the robot to comprehend and execute complex task commands, thereby fostering a new mode of interaction for human-robot collaboration.

Collaborative Dual-Arm Operations: Flexible Functionality and Efficient Performance

The embodied intelligent industrial robot is designed for dual-arm collaborative operations, combining high rigidity with high flexibility. With 12 to 19 flexible joints, it overcomes the limitations of traditional industrial robots, which struggle with synchronized movements in complex working conditions. This robot can easily handle a variety of tasks, including tightening bottle caps, scanning barcodes, and precision assembly. It has a single-arm load capacity of 3 kg, making it suitable for a range of industrial scenarios and capable of meeting diverse task requirements.

Dynamic Optimization and AI Learning: Intelligent Progression and Adaptation for the Future

By integrating dynamic optimization algorithms with reinforcement learning, intelligent industrial robots can solve complex challenges using hybrid optimization techniques that combine model-based dynamic programming with model-free reinforcement learning methods. In dynamic environments, effective path planning is achieved through deep reinforcement learning. The data-driven and autonomous learning capabilities of AI technology significantly enhance the dynamic optimization performance of dual-arm systems, allowing them to continually adapt to new tasks and environmental changes. This leads to ongoing optimization and self-improvement.

Various Application Scenarios: Empowering Multiple Fields and Adding Value

Embodied intelligent industrial robots have demonstrated significant potential and value across various fields. In industrial manufacturing, they can be utilized for quality inspection on automotive production lines, handling heavy equipment, and assembling precision electronic components. In commercial services, these robots offer intelligent solutions for a range of business scenarios, thereby enhancing customer experience and operational efficiency.

In the medical and scientific research sectors, they can assist medical professionals in performing various tasks, support researchers in their experiments, and contribute to advancements in medical technology and scientific inquiry.

In the realm of education and development, their open-source ROS platform facilitates secondary development and algorithm research. The educational suite covers topics such as path planning and visual recognition, providing robust support for education and scientific research while nurturing future talents in science and technology innovation.

Intelligent Operation and Maintenance, Digital Empowerment

With the adoption of new technologies like big data, cloud computing, and the Internet of Things, more industrial enterprises are pursuing digitalization, networking, and intelligent automation, gradually advancing towards “enterprise cloudification.”

- Real-time Status Monitoring and Early Warning: By implementing a multi-dimensional sensor network, we can continuously collect status data such as vibration, temperature, and current from key equipment components. This allows us to identify and alert users to abnormal operating conditions at an early stage.

- Big Data Analysis and Predictive Maintenance: We utilize machine learning algorithms to create models that assess the health and degradation of equipment. This enables us to accurately predict the remaining service life of essential components, such as spindles and cutting tools. By shifting from passive maintenance to proactive prevention, we can maximize equipment availability.

- Cloud Collaboration and Remote Support: We have established a remote operations and maintenance center, along with an expert knowledge base. This setup supports centralized monitoring, fault diagnosis, and program optimization for equipment across various locations. It facilitates rapid responses to on-site needs while reducing operation and maintenance costs.

HuazhongCNC’s intelligent solutions are widely applied in key sectors such as new energy vehicles, energy equipment, and general precision manufacturing.

In the area of key components, our solutions ensure efficient, high-precision, and reliable machining of large structural parts and core engine components. In the new energy vehicle sector, we offer a comprehensive solution that integrates CNC machining with robotic collaboration for flexible production lines focused on core components, including battery trays and motor housings.

Additionally, we assist users in establishing a transparent equipment management platform, facilitating the digital transformation of operation and maintenance models in equipment operation and maintenance.

From our independent research and development of key technologies to the implementation of industry solutions, we are enhancing the future factory experience through the three-dimensional integration of the “HNC10 Intelligent CNC System, Embossed Intelligent Robot, and Intelligent Operation and Maintenance.” Our aim is to create a more agile, precise, and reliable manufacturing environment.