HNC assists in the intelligent manufacturing of five-axis molds for new energy vehicles

A New Era: New Energy Vehicles Create New Opportunities for the Industry

In the era of traditional gasoline-powered vehicles, the requirements for machining precision and the reliability of core components—such as engines and transmissions—were extremely stringent. Domestic high-end machine tools struggled to match the stability found in products from countries like Germany, Japan, and Switzerland, resulting in a heavy reliance on imported five-axis CNC machine tools for high-end automotive production lines. Recent market data indicates that German, Japanese, and American brands have dominated the top 25 best-selling sedans in China. The supply chains of these automakers are largely connected to domestic machine tool brands, which makes it challenging for traditional domestic machine tool companies to enter the high-end market.

The rise of new energy vehicles has completely disrupted this pattern. Their core has shifted to batteries, motors, and electronic controls. This structural change has significantly weakened the West’s technological advantage in traditional engine manufacturing, putting domestic and foreign companies on a much closer starting line. New processing requirements are better suited to the characteristics of domestically produced equipment: battery trays require large gantry milling machines, emphasizing high efficiency and large-scale production; the motor housing structure is relatively simple, reducing processing difficulty and precisely avoiding the traditional weaknesses of domestically produced machine tools.

China has become the world’s largest new energy vehicle market. According to data from the China Association of Automobile Manufacturers, in 2008, my country’s new energy vehicle sales were only 1,500 units, accounting for approximately 0.0016% of the global market. By 2023, sales had soared to 9.495 million units, accounting for 31.6% of the global market and exceeding 60% of the global market share. By 2024, sales were projected to exceed 10 million units, with the domestic market accounting for 40.9% and the global market share exceeding 70%. Domestic OEMs such as BYD have been actively promoting the localization of their supply chains, providing valuable opportunities for trial and error and iteration for domestically produced equipment. Taking a best-selling BYD model as an example, its starting price has dropped to a highly competitive range, yet it still maintains considerable profit margin per vehicle. One of the core reasons is the use of domestically produced machine tools and CNC systems, fully highlighting the high cost-performance advantage of domestically produced equipment in terms of both quality and cost.

Core Strength: The HNC8 Five-Axis System Sets a New Standard for High-End Machining

As a leader in the domestic CNC field, HNC has been deeply involved in the industry for thirty years, with continuous technological iteration: In 1994, it developed the HNC Type I nine-axis linkage CNC system; in 2000, the HNC Century Star 21/22 series CNC system was recognized as a national independent innovation product; in 2008, the HNC8 CNC system was launched, realizing the leap of domestic high-end CNC systems from analog and pulse-type to all-digital and bus-type; in 2023, the HNC8 five-axis CNC system product package was officially released, becoming a core tool for high-end mold processing.

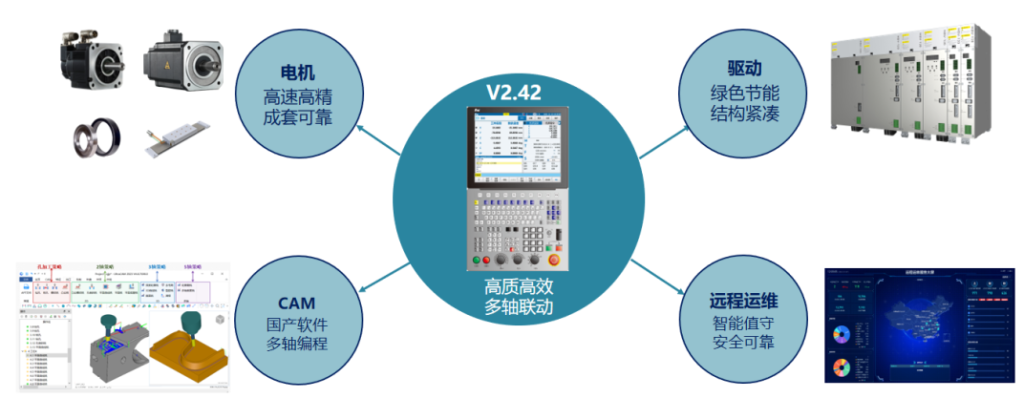

HNC8 5-axis CNC system product package: a comprehensive hardware and software solution.

This product package represents a remarkable achievement developed by HNC in partnership with leading domestic machine tool companies. A collaborative research team carried out 16 rounds of “100-day intensive research” projects, dedicating over 1,200 person-hours to their development. The package includes two essential components: hardware and software systems, which together fully meet the precision requirements for high-end mold processing.

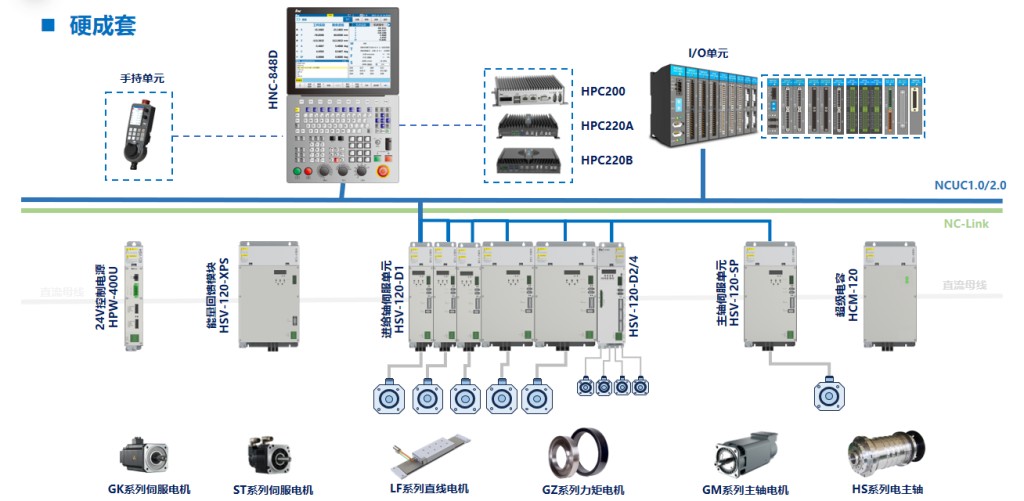

Hardware System: Robust Hardware, Solid Foundation for Precision

The hardware system integrates a complete hardware chain from drive units to motor components, with performance comparable to top international standards.

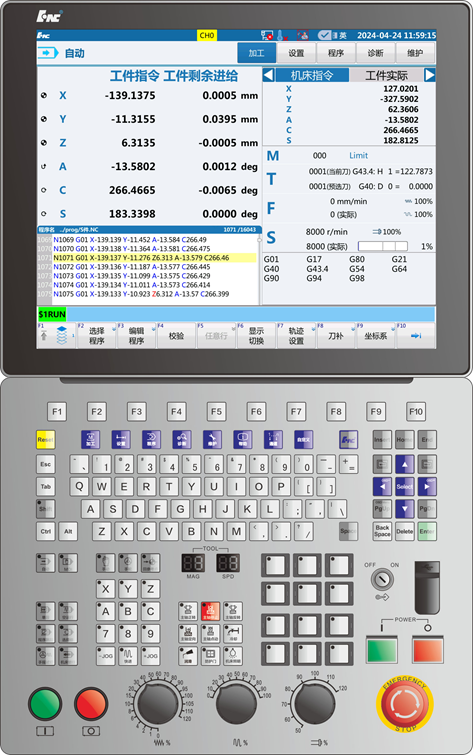

High-performance CNC system

This advanced CNC system offers exceptional capabilities, supporting 8 channels and 80 axes of control. Each channel can precisely manage 9 feed axes and 4 spindles, making it adaptable to various machine models, including 5-axis, mill-turn composites, and multi-axis multi-channel setups.

The system is equipped with a high-performance IPC unit that allows for 500M of program online editing, significantly enhancing machining flexibility and efficiency. Additionally, it features a 17-inch high-resolution touchscreen, providing an intuitive and convenient operation experience. The interface supports multiple languages, including Chinese and English, catering to diverse user needs across different scenarios.

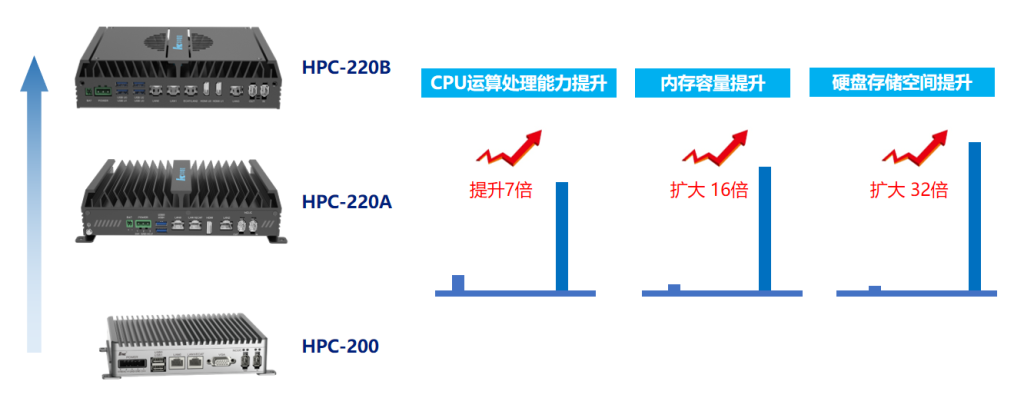

High-performance HPC units

Equipped with high-performance HPC units, including models such as HPC-220B, HPC-220A, and HPC-200, we have made significant advancements in core performance. CPU processing power has increased by seven times, memory capacity has expanded by sixteen times, and hard disk storage space has grown by thirty-two times. This powerful hardware capability ensures reliable operation for complex programs and multi-axis collaborative control. As a result, we are achieving breakthroughs in efficiency and accuracy in high-precision intelligent manufacturing scenarios, such as mold processing.

High-performance modular servo drive units

Includes the spindle servo unit HSV-120-SP, feed axis servo units HSV-120-D1, HSV-120-D2/4, etc., paired with the energy feedback module HSV-120-XPS to achieve green and energy-saving operation. The HSV120/HSV130 series servo drive units adopt the NCUC industrial-grade fieldbus, a modular structure with a common DC bus, support for multiple encoder protocols and dual-code disk full closed-loop control, hardware current loop and vibration damping filter to ensure high-precision response, power module supports energy feedback, capacitor module provides power failure backoff protection, and are compatible with 1-250KW servo motors, covering various machining scenarios.

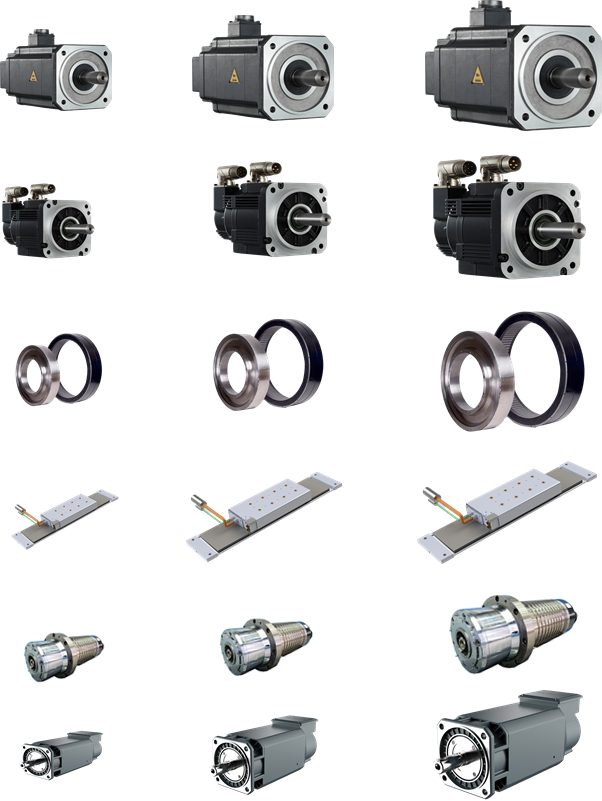

High-Performance Motor Series

The GK7/180ST/GZ6A/LF/HS/GM9 series includes servo motors, torque motors, linear motors, and spindle motors. Servo motors can reach speeds of up to 6000 rpm, and electric spindles can reach speeds of up to 30000 rpm. Cogging torque is as low as 0.3%, ensuring smooth, vibration-free operation. A 3x overload capacity allows acceleration greater than 1G. A 16 million-line high-resolution encoder achieves micron-level positioning. Torque density is increased by 20%, resulting in a more compact size. IP67 protection rating adapts to complex machining environments. Power ranges from 1KW to 250KW, flexibly meeting diverse load requirements.