The Dual-Control System Enhances Intelligent Manufacturing: Efficient Collaboration Boosts Production Capacity.

HNC8 & Dual-Control System Empower Intelligent Manufacturing

Leading the way in intelligent manufacturing, many companies are transforming their production workshops to enhance efficiency. An increasing number of production lines are now utilizing the “Dual-Control” gantry robot solution powered by the HNC8 high-end CNC system. As a result, these companies have successfully overcome the efficiency limitations of traditional automated production lines, marking a significant advancement in “cost reduction and efficiency improvement” in intelligent manufacturing.

HNC’s “Dual-Control” gantry robot solution currently serves various industries, including motor manufacturing, joint bearing production, grinding screw fabrication, linear guide and bearing manufacturing, temperature control product manufacturing, and hydraulic pipe fitting production.

Mass production of truss robots from HICNC is currently underway in the sectors of motor manufacturing, transmission component manufacturing, and temperature control product manufacturing. Similarly, in the hydraulic pipe fitting manufacturing sector, Huazhong CNC is also producing truss robots using the same “one brain, two controls” architecture.

Highly Efficient Collaborative Machining Automation Solutions

In traditional gantry robot automation systems, achieving collaborative operation between two robots typically requires separate control systems for each. This approach not only leads to increased hardware costs and more complex wiring, but it also creates challenges such as prolonged debugging cycles, difficulties in ensuring accurate collaboration, and delays in information exchange. These issues ultimately hinder the maximization of automation efficiency.

“HCNC’s ‘One Brain, Two Controls’ solution is an excellent choice for upgrading our production line automation,” stated a production manager at a manufacturing company. “Not only does it significantly reduce our equipment investment costs, but, more importantly, the high level of collaboration achieved by the two robots operating under the same ‘brain’ has greatly improved our production efficiency. It has maximized equipment usage, facilitated smoother product flow, and simplified maintenance and management. This solution provides a solid foundation for enhancing our market competitiveness.”

Intelligent Core, Dual Control

HuazhongCNC’s innovative “Dual Control” gantry robot solution, which utilizes the HuazhongCNC Model 8 high-end CNC system as its core “intelligent brain,” introduces a highly efficient collaborative operation mode. This system enables precise simultaneous control of both the machine tool and the gantry robot by a single platform. As a result, enterprises can achieve significant cost reductions and improvements in efficiency.

Significantly Reduced Hardware Costs: By eliminating the need for a separate control system and its associated electrical cabinets, cables, and other hardware, initial equipment procurement costs are significantly reduced.

Seamless Collaboration and Enhanced Efficiency: Direct control of both the machine tool and the robot by a single system eliminates communication delays and synchronization errors between the two systems, resulting in complete control. The machine tool and robot are precisely controlled as if by the same nerve, enabling “zero-wait” relay coordination in processes such as material handling, assembly, and inspection. This significantly improves overall equipment utilization (OEE) and drastically reduces production cycle time.

Streamlined Debugging and Maintenance: Programming, debugging, and maintenance are handled by a single system. This simplifies operations, decreases production line deployment time, and reduces the complexity of personnel training and operational costs.

Optimized spatial design: The streamlined control system frees up important equipment space, making the production line layout more compact and flexible.

Easy to operate and fully functional

Addressing typical pain points in production and processing, HuazhongCNC’s “One Brain, Two Controls” gantry robot provides comprehensive solutions, consistently creating an efficient and convenient production mode for users.

Automatic Chip Breaking Function: In production and processing, tangled metal chips not only hinder automated loading and unloading but also damage workpiece surface quality and even cut operators. HuazhongCNC utilizes low-frequency reciprocating movement along the cutting axis to create “air vibration” time, breaking down chips into smaller pieces and discharging them intermittently. This eliminates the negative impact of metal chips on processing efficiency, making it suitable for chip breaking of difficult-to-machine materials. Applicable to linear guide machine tools such as horizontal/slant lathes, vertical lathes, and turning centers;

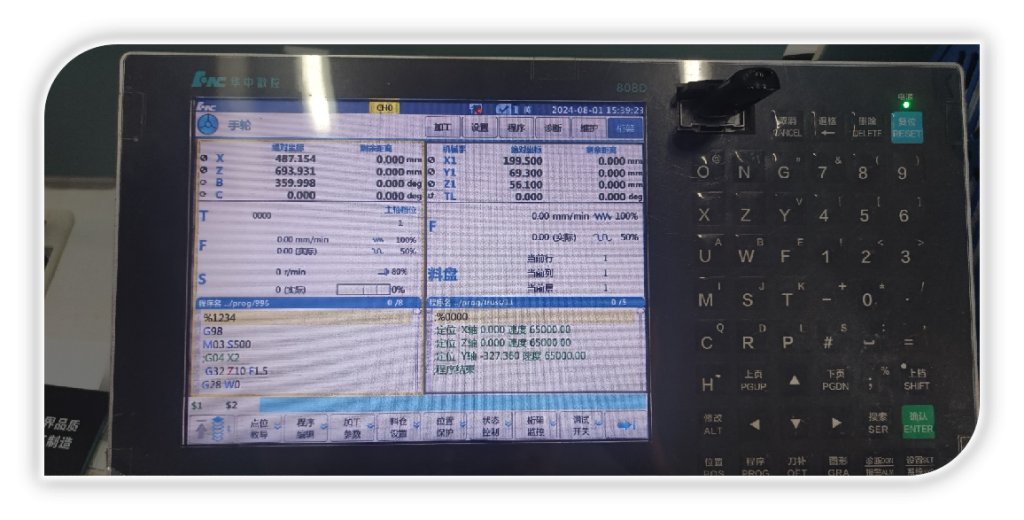

Motion Simulation Function and Easy Display: The HNC8 high-end CNC system can simulate the gantry’s operation in real time, displaying the gantry’s position and speed, showing the current material pick-up position of the tray, monitoring the current status of the blank and finished product claws, and prompting the gantry’s current and next actions.

Additionally, while typical dual-channel displays utilize G-code, the HNC8 high-end CNC system’s dual-channel interface can display Chinese programs and automatically convert them into G-code for execution.

Robot Overload Protection: The robot’s overload protection function continuously monitors the load current during low-speed movements, such as loading and unloading. It compares this current in real-time with a predetermined threshold. In the event of even a minor collision, the system immediately activates an alarm and stops the gantry from moving. This prevents driver alarms and protects the gantry from potential damage.

Collision Avoidance: The system includes dynamic collision avoidance and protection. Both the machine tool and gantry can stop, and the gantry has a retraction function.

Effective collaboration leads to adaptable production lines.

In practical applications, gantry robots that utilize the HNC8 high-end CNC system and feature a “one brain, two controls” design showcase their capabilities in the precision machining of essential transmission components and automated assembly lines.

Highly Efficient and Precise Loading and Unloading: With a unified scheduling system, the gantry robots operate seamlessly together. They accurately pick up raw materials and feed them into the machine tools, then remove the finished products and transfer them to the next workstation or inspection area. This process achieves continuous operation of the machine tools with “zero-interval” downtime.

Flexible Production Line Support: The HNC8 high-end CNC system offers exceptional scalability and openness. Together with the flexibility of its “one brain, two controls” feature, Auboson can swiftly adapt to the production requirements of various small batches. This capability enables easy adjustments to task allocation and collaboration between the two robots, ultimately enhancing the overall flexibility of the production line.

The successful adoption of HuazhongCNC’s “one brain, two controls” gantry robot solution by manufacturing enterprises showcases how domestic high-end CNC technology supports intelligent manufacturing. With its exceptional control performance and innovative integrated architecture, the HNC8 high-end CNC system offers the manufacturing industry a more economical, efficient, and intelligent route to automation upgrades. This technology continuously assists Chinese manufacturing enterprises in enhancing their core competitiveness and accelerates their progress towards high-quality development.