HNC8 Milling and Turning Machining Solution

What is a Milling-Turning Machining Center?

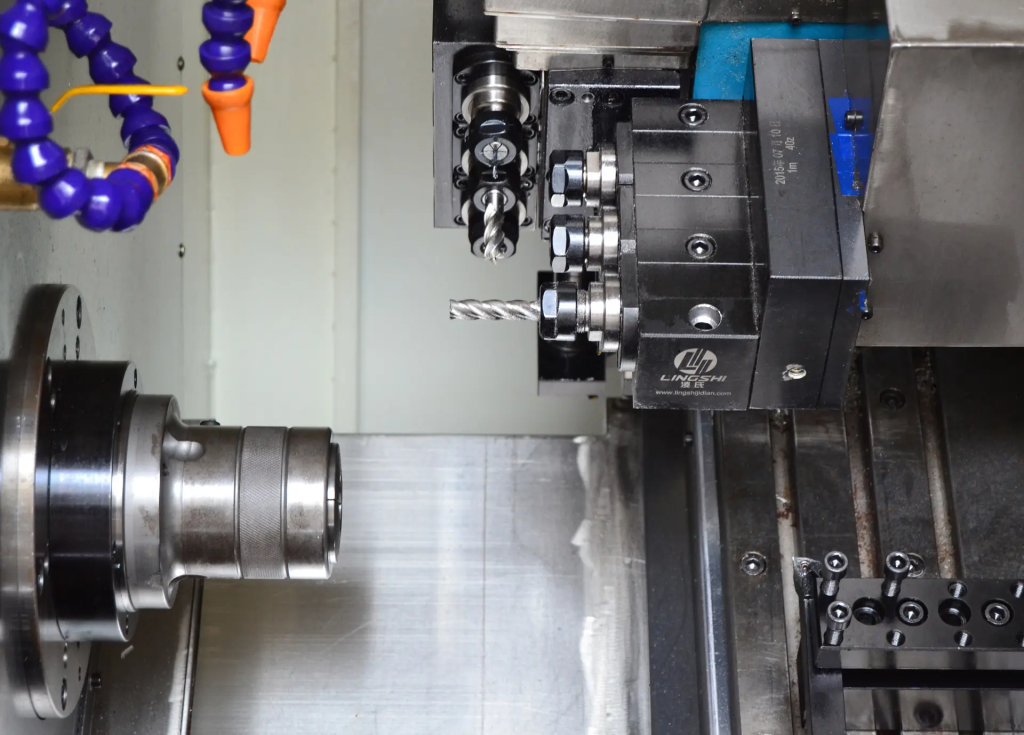

A milling-turning machining center is a machine tool that utilizes milling-turning machining technology to perform milling and turning operations simultaneously. It is essentially a combination of a CNC lathe and a machining center. Milling-turning machining centers typically have five axes: x, y, z, a, and c. Through multi-axis linkage, they can achieve milling-turning machining, and are adept at machining spatial curved surfaces, irregular shapes, hollowing, drilling, angled holes, and bevel cutting.

Milling-turning machining is one of the most advanced machining processes internationally, representing an advanced manufacturing technology and representing the fastest-growing and most widely used CNC equipment among composite machining tools.

Types of Mill-Turn Turning Machines

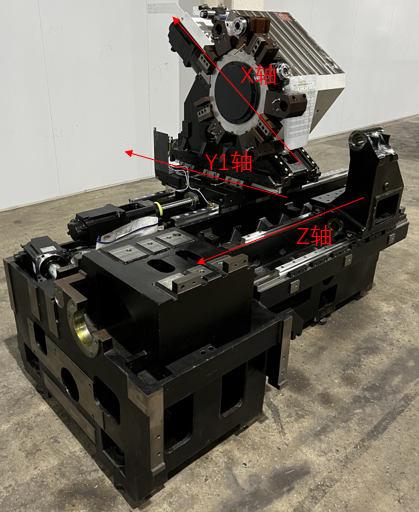

Popular mill-turn machining centers enhance standard turning machines by incorporating a Y-axis in addition to the powered turret. There are two main types of mill-turn machines: one features an orthogonal Y-axis, where the X and Y axes intersect at right angles, while the other uses a virtual Y-axis, in which the angle between the Y1 axis guide and the X axis is not a right angle. Typically, the angle between the X and Y1 axes is -35 degrees.

What are the advantages of mill-turn machines?

1. Shortened manufacturing process chain and improved production efficiency. Mill-turn turning can complete all or most machining operations in a single setup, significantly shortening the manufacturing process chain. This reduces auxiliary production time caused by changes in setup, as well as tooling manufacturing cycle and waiting time, significantly improving production efficiency.

2. Reduced clamping times and improved machining accuracy. Reduced clamping times to avoid error accumulation caused by changes in positioning references. Furthermore, most mill-turn turning machines have online monitoring capabilities, enabling in-situ monitoring and accuracy control of key manufacturing data, thereby improving product machining accuracy.

3. Reduced footprint and lower production costs. Although the unit price of mill-turn machining center equipment is relatively high, the reduction in the manufacturing process chain, the number of equipment required for the product, the number of tooling fixtures, the workshop floor space, and the equipment maintenance costs can effectively reduce the overall fixed asset investment, production operation, and management costs.

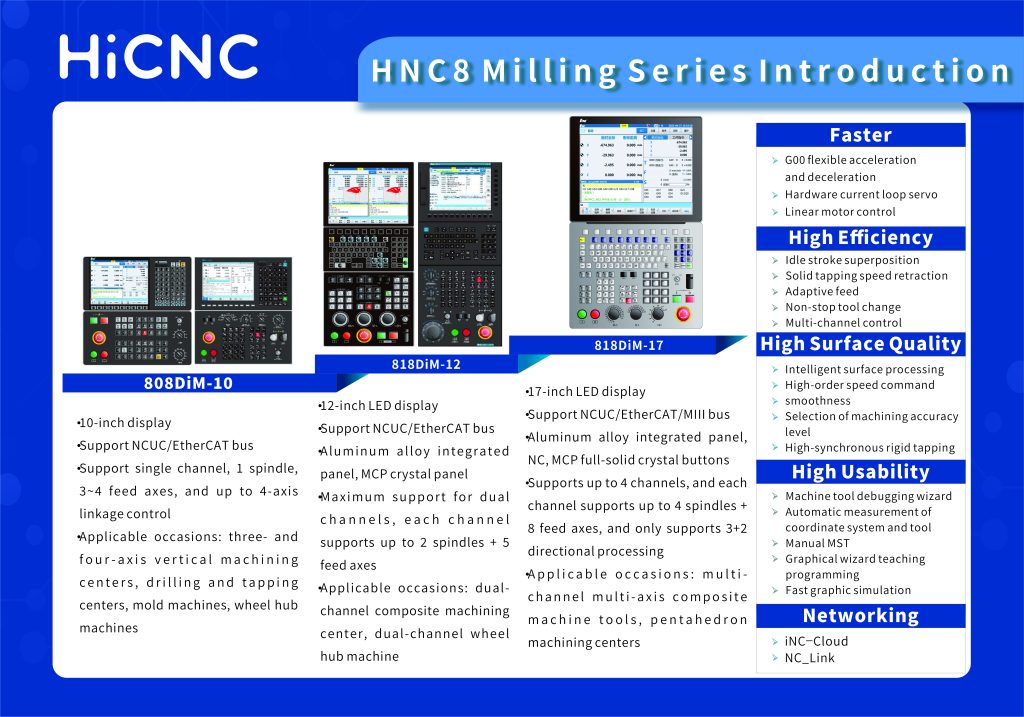

HNC 8 Milling and Turning Composite CNC System

High-Performance IPC

- IPC200 unit, fanless fully enclosed structure, industrial-grade control unit, maximum operating temperature up to 55℃;

- Adopts Atom series processor, lower power consumption, higher processing speed; standard 8GB solid-state drive, supports ultra-large programs, 1GB memory, overall performance improvement of 50%;

- Supports both NCUC and EtherCAT bus protocols.

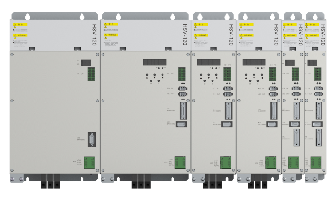

Modular All-in-One Servo Drive

- AC380V input

- Compact, modular multi-axis drive system with a small assembly size, saving cabinet space.

- Supports regenerative power modules for energy feedback.

- Equipped with a power failure protection module to prevent gravity axis drop during accidental power outages and supports tool retraction.

- Supports NCUC bus and various encoder types.

- 120 model is compatible with 3.0~7.5kW AC servo motors or 5.5~11kW AC spindle motors.

- 130 model is compatible with 5.5~55kW AC servo motors or 5.5~55kW AC spindle motors.

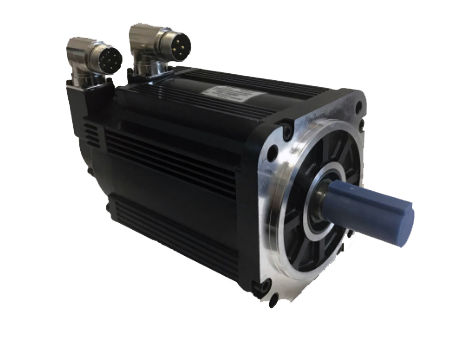

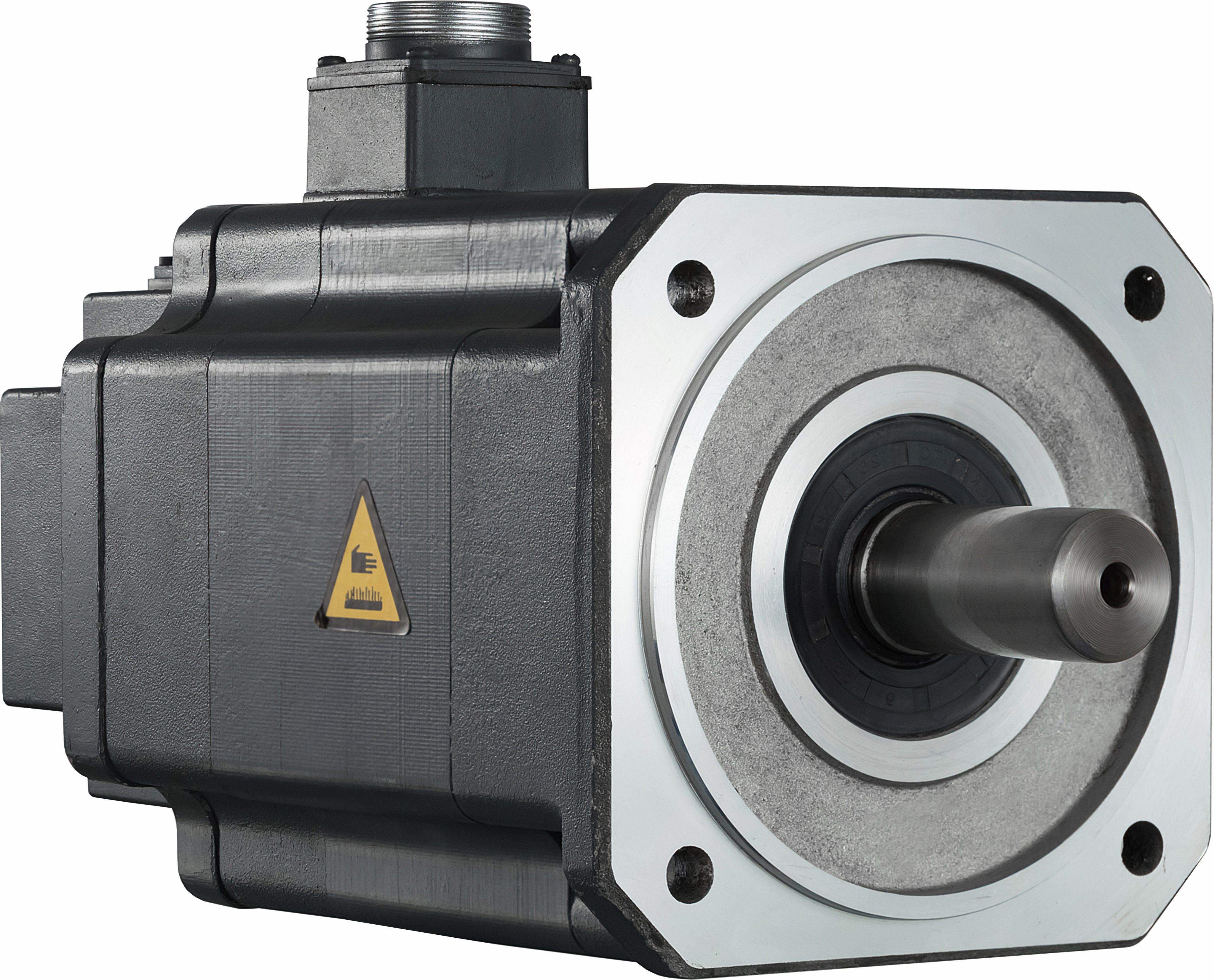

High-performance servo motor

| LDD Series Low-voltage feed motor |  | · High torque density · High efficiency density · Low cogging torque · High response frequency · High smoothness · Process stability with excellent product consistency |

| GK Series High-voltage feed motor |  | · High torque, high power density · High speed, wide output range · Low torque ripple · High rotational accuracy · Robust construction · Compatible with multiple encoders Permanent magnetism retention |

| GM Series High-voltage spindle motor |  | · High torque-to-inertia ratio with fast dynamic response; · High efficiency and energy savings; · Compact size and lightweight design; · Stable manufacturing process with excellent product consistency; · Low noise and vibration with extended service life; · High rotational speed; |